Silicon dioxide nanofiber/polyimide composite aerogel as well as preparation method and application thereof

A composite aerogel and nanofiber technology, used in applications, other household appliances, ceramic products, etc., can solve the problems of brittleness and poor flexibility of aerogel, and achieve the effect of improving continuity, excellent elasticity and avoiding collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

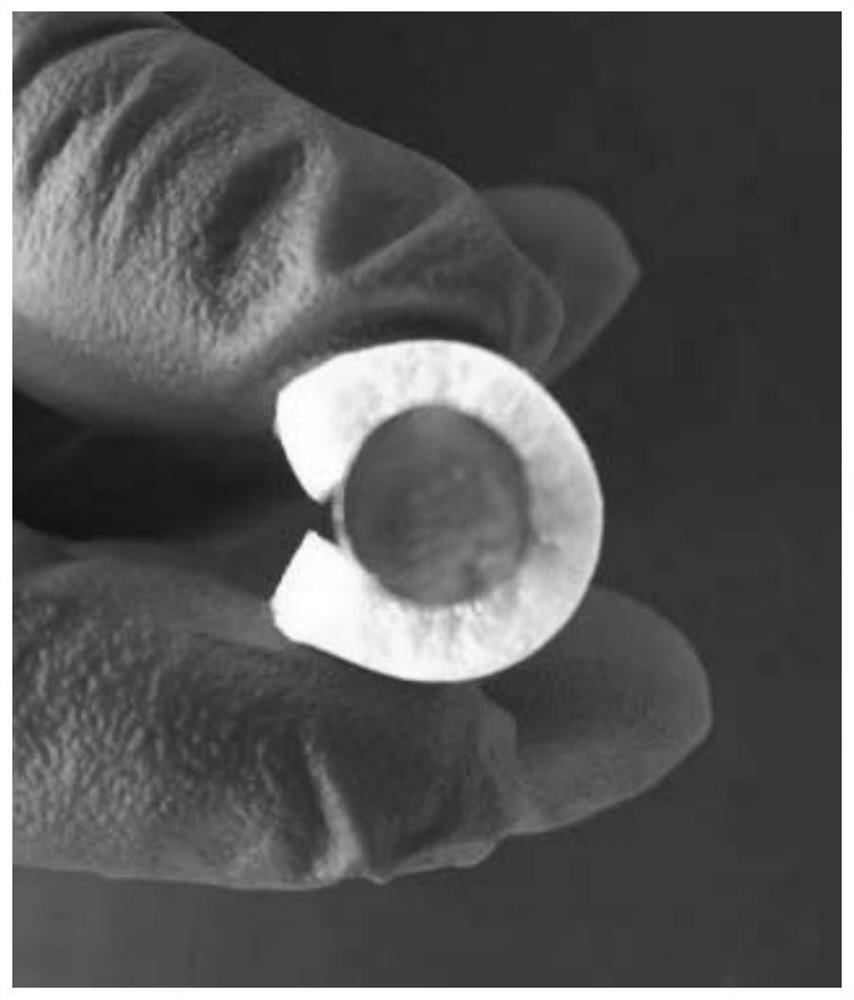

Image

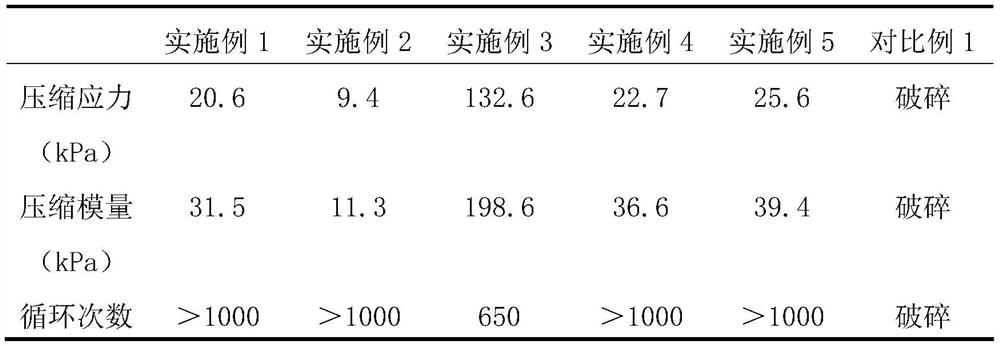

Examples

Embodiment 1

[0025] 1. Weigh tetraethyl orthosilicate / phosphoric acid / deionized water and mix at a molar ratio of 1:0.01:10, stir at room temperature for 10 hours to obtain a silica precursor sol; weigh 1g of polyvinyl alcohol and dissolve it in 9g of deionized In water, stir at 80°C for 5h to obtain 10wt% polyvinyl alcohol aqueous solution; mix silica precursor sol / polyvinyl alcohol aqueous solution at a mass ratio of 1:1, stir at room temperature for 8h to obtain spinning solution, and transfer the spinning solution into a syringe Among them, the fiber membrane is obtained by electrospinning, the spinning temperature is 25°C, the spinning liquid propulsion speed is 1ml / h, the voltage is 15kV, and the receiving distance of the drum is 15cm. Fibrous membrane with a diameter of 100-400nm.

[0026] 2. Weigh 4.31g of 4,4'-diaminodiphenyl ether (ODA) and completely dissolve it in 51g of N,N-dimethylacetamide, add 4.69g of pyromellitic dianhydride (PMDA) and stir at 0°C 4h, then add 2.18g trie...

Embodiment 2

[0031]1. Weigh methyl orthosilicate / phosphoric acid / deionized water and mix in a molar ratio of 1:0.01:10, stir at room temperature for 10 hours to obtain a silica precursor sol; weigh 1g of polyvinyl alcohol, dissolve in 9g of deionized In water, stirred at 80°C for 5h to obtain a 10wt% poly(vinyl butyral) aqueous solution; the silica precursor sol / poly(vinyl butyral) aqueous solution was mixed at a mass ratio of 1:1, stirred at room temperature for 8h, and a spinning solution was obtained. Silk liquid, the spinning liquid is transferred into the syringe, and the fiber film is obtained by electrospinning. The spinning temperature is 25°C, the spinning liquid advancing speed is 1ml / h, the voltage is 15kV, and the receiving distance of the drum is 15cm. The obtained spinning film Treating at a high temperature of 600° C. for 10 h to obtain a silica nanofiber membrane with a diameter of 100-400 nm.

[0032] 2. Weigh 2.33g of p-phenylenediamine, dissolve it completely in 51g of N...

Embodiment 3

[0037] 1. Weigh tetraethyl orthosilicate / phosphoric acid / deionized water and mix them in a molar ratio of 1:0.01:10, stir at room temperature for 10 hours to obtain a silica precursor sol; weigh 1g of polyvinylpyrrolidone and dissolve in 9g of deionized In water, stir at 80°C for 5 hours to obtain 10wt% polyvinylpyrrolidone aqueous solution; mix silica precursor sol / polyvinylpyrrolidone aqueous solution at a mass ratio of 1:1, stir at room temperature for 8 hours to obtain spinning solution, and transfer the spinning solution into a syringe Among them, the fiber membrane was obtained by electrospinning, the spinning temperature was 25°C, the spinning liquid propulsion speed was 1ml / h, the voltage was 15kV, the receiving distance of the drum was 15cm, and the obtained spinning membrane was treated at a high temperature of 900°C for 0.5h to obtain silica The nanofibrous membrane has a diameter of 100-400nm.

[0038] 2. Weigh 2.33g of p-phenylenediamine, dissolve it completely in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com