Europium dysprosium co-doped tungstate red fluorescent powder for white light LED and preparation method of europium dysprosium co-doped tungstate red fluorescent powder

A red phosphor powder and co-doping technology, which is applied in the field of fluorescent materials, can solve the problems of low color rendering index, lack of red components, and low luminous efficiency of white LEDs, achieve low calcining temperature, abundant raw material resources, and improve display efficiency. Effect of color index and color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

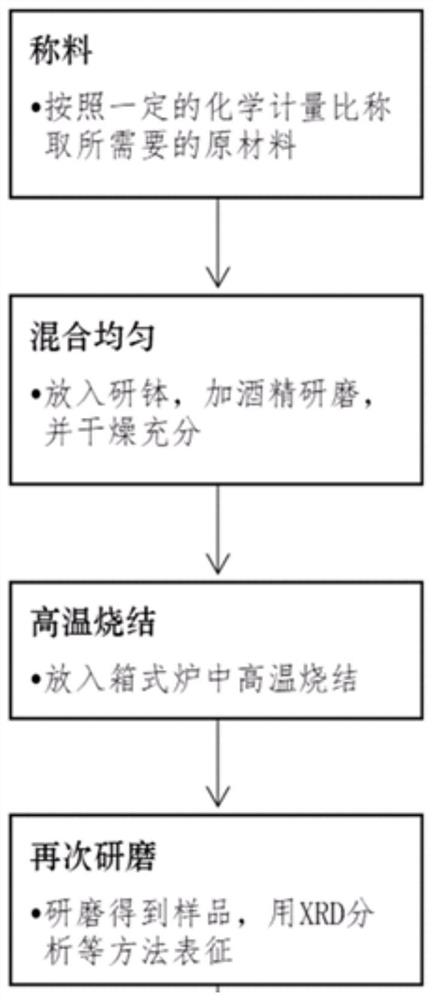

[0040] use as figure 1 LiSrGd was prepared by the traditional high-temperature solid-state method shown in 0.97 (WO 4 ) 3 :0.01Eu 3+ ,0.02Dy 3+ Phosphor powder, the steps are as follows:

[0041] (1) Weighing: according to the target product LiSrGd 0.97 (WO 4 ) 3 :0.01Eu 3+ ,0.02Dy 3+ Calculate the stoichiometric ratio in the fluorescent powder to obtain the amount of each raw material, and use an electronic balance to obtain a suitable quality of raw material;

[0042] (2) Mix evenly: Mix the raw materials evenly and put them into an agate mortar, add absolute ethanol and grind for 1 hour, after the absolute ethanol evaporates cleanly, grind the raw materials evenly and place them in a corundum crucible, and dry them completely in an electronic drying oven;

[0043] (3) High temperature sintering: put the dried sample together with the corundum crucible into a high temperature box furnace, and calcinate at 900°C for 4 hours;

[0044] (4) Secondary grinding: After t...

Embodiment 2

[0053] Preparation of LiSrGd in this embodiment 0.9 (WO 4 ) 3 :0.05Eu 3+ , 0.05 Dy 3+ Phosphor powder, the steps are as follows:

[0054] (1) Weighing: according to the target product LiSrGd 0.9 (WO 4 ) 3 :0.05Eu 3+ , 0.05 Dy 3+ The stoichiometric ratio in the phosphor is used to calculate the amount of raw materials for compounds containing Li, Sr, Gd, W, Eu, and Dy elements, and use an electronic balance to obtain raw materials of appropriate quality;

[0055] (2) Mix evenly: mix the raw materials evenly and put them in an agate mortar, add absolute ethanol and grind for 0.5h, after the absolute ethanol evaporates, put the raw materials evenly in a corundum crucible, and dry them completely in an electronic drying oven;

[0056] (3) High-temperature sintering: put the dried sample together with the corundum crucible into a high-temperature box furnace, and calcinate at 850°C for 3 hours;

[0057] (4) Secondary grinding: After the reaction is completely completed, t...

Embodiment 3

[0060] Preparation of LiSrGd in this embodiment 0.98 (WO 4 ) 3 :0.01Eu 3+ ,0.01Dy 3+ Phosphor powder, the steps are as follows:

[0061] (1) Weighing: according to the target product LiSrGd 0.98 (WO 4 ) 3 :0.01Eu 3+ ,0.01Dy 3+ Calculate the stoichiometric ratio in the phosphor to obtain the amount of raw materials for compounds containing Li, Sr, Gd, W, Eu, and Dy elements, and use an electronic balance to obtain raw materials of appropriate quality;

[0062] (2) Mix evenly: Mix the raw materials evenly and put them into an agate mortar, add absolute ethanol and grind for 1.5 hours, after the absolute ethanol evaporates, put the raw materials evenly in a corundum crucible, and dry them completely in an electronic drying oven;

[0063] (3) High temperature sintering: put the dried sample together with the corundum crucible into a high temperature box furnace, and calcinate at 950°C for 5 hours;

[0064] (4) Secondary grinding: After the reaction is completely complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com