Preparation method of high-flexibility integral carbon nanofiber membrane

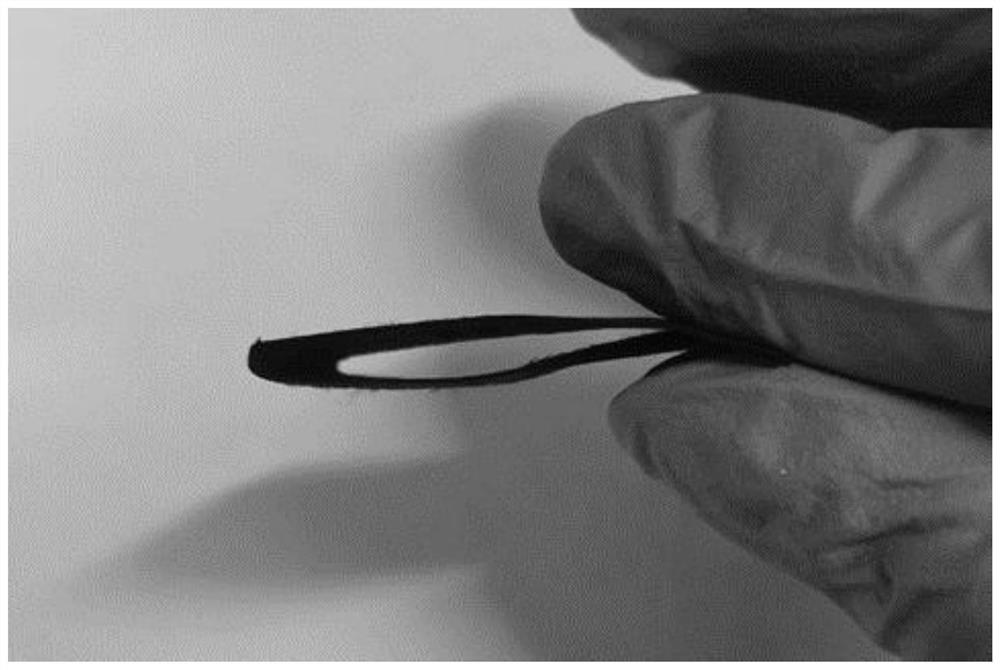

A nano-carbon fiber, monolithic technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high raw material cost, poor conductivity, and poor flexibility of flexible nanocarbon fiber membranes, etc. Achieve the effects of high specific capacitance, high value-added utilization, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

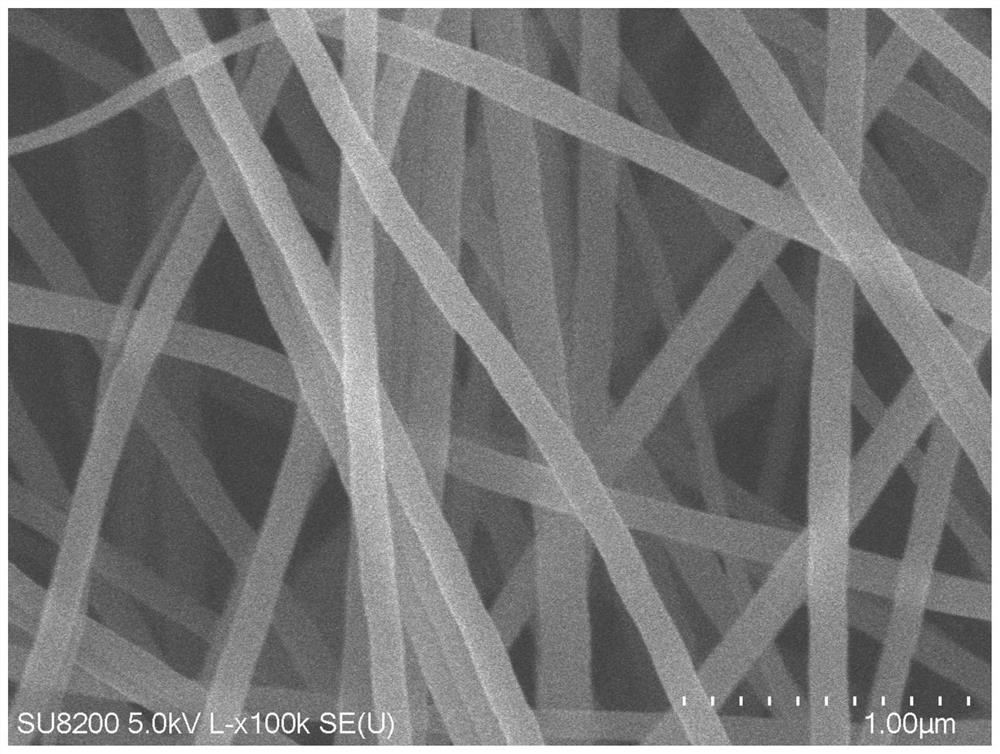

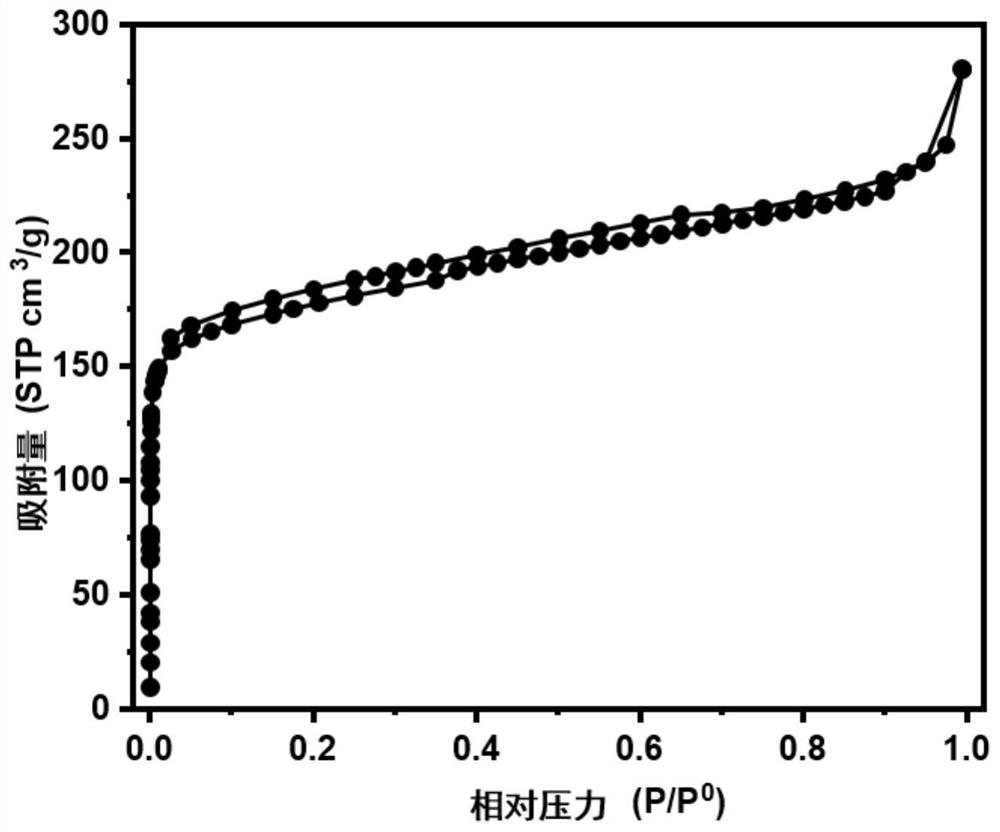

Method used

Image

Examples

Embodiment 1

[0040] According to the preparation method of the highly flexible monolithic carbon nanofiber membrane of this embodiment, using delayed coking petroleum coke as a raw material, the following steps are sequentially included:

[0041] (1) Crushing the petroleum coke with a pulverizer, and screening through a 200-mesh sieve to obtain petroleum coke powder.

[0042] (2) Add 4 g of the petroleum coke powder obtained in step (1) to a mixed acid with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1, and treat for 2 hours under reflux in a water bath at 80°C.

[0043] (3) The petroleum coke powder treated with the mixed acid solution obtained in step (2) is washed to neutrality, and dried to obtain oxidized petroleum coke powder.

[0044] (4) Dissolve 0.5 g of the oxidized petroleum coke powder obtained in step (3) and 1.0 g of spinning aid polyvinylpyrrolidone in 10 ml of N,N-dimethylformamide to obtain an electrospinning solution. That is, the mass ...

Embodiment 2

[0050] (1) Crushing the petroleum coke with a pulverizer, and screening through a 200-mesh sieve to obtain petroleum coke powder.

[0051] (2) Add 4 g of the petroleum coke powder obtained in step (1) to a mixed acid with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1, and treat it at 80°C under reflux in a water bath for 2 hours.

[0052] (3) The petroleum coke powder treated with the mixed acid solution obtained in step (2) is washed to neutrality, and dried to obtain oxidized petroleum coke powder.

[0053] (4) Dissolve 0.8 g of the oxidized petroleum coke powder obtained in step (3) and 0.7 g of polyvinylpyrrolidone spinning aid in 10 ml of N,N-dimethylformamide to obtain an electrospinning solution. That is, the mass fraction of oxidized petroleum coke is 7.3%, the mass fraction of polyvinylpyrrolidone as a spinning aid is 6.4%, and an electrospinning precursor solution is configured.

[0054] (5), the temperature of the electrospinning ...

Embodiment 3

[0059] (1) Crushing the petroleum coke with a pulverizer, and screening through a 200-mesh sieve to obtain petroleum coke powder.

[0060] (2) Add 4 g of the petroleum coke powder obtained in step (1) to a mixed acid with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1, and treat it at 80°C under reflux in a water bath for 2 hours.

[0061] (3) The petroleum coke powder treated with the mixed acid solution obtained in step (2) is washed to neutrality, and dried to obtain oxidized petroleum coke powder.

[0062] (4) Dissolve 1.0 g of the oxidized petroleum coke powder obtained in step (3) and 0.5 g of polyvinylpyrrolidone spinning aid in 10 ml of N,N-dimethylformamide to obtain an electrospinning solution. That is, the mass fraction of the oxidized petroleum coke is 9.1%, the mass fraction of the spinning aid polyvinylpyrrolidone is 4.6%, and the electrospinning precursor solution is configured.

[0063] (5), the temperature of the electrospinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com