Electrolyte of silicon-carbon negative electrode lithium ion battery and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of continuous consumption of electrolyte, deterioration of battery performance, increase of battery internal resistance, etc., to improve battery gas production, reduce battery internal resistance, and suppress thickness increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

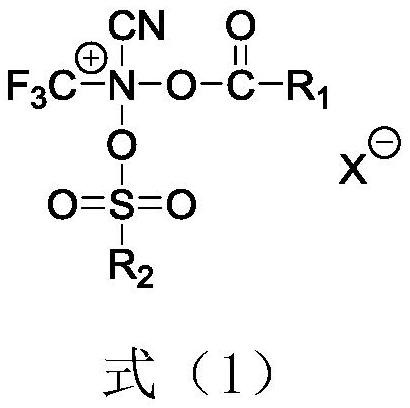

[0026] An electrolyte solution for a silicon-carbon negative electrode lithium-ion battery, comprising an electrolyte lithium salt, a non-aqueous organic solvent, a film-forming additive and a high-temperature-resistant additive, wherein the high-temperature-resistant additive is compound 1, and the structural formula of compound 1 is as follows:

[0027]

[0028] The mass of compound 1 accounts for 0.05% of the total mass of the electrolyte;

[0029] The electrolyte lithium salt is LiPF 6 , LiPF 6 The mass accounts for 12.5% of the total mass of the electrolyte;

[0030] The film-forming additive is vinyl sulfate, and the quality of vinyl sulfate accounts for 2.5% of the total mass of the electrolyte;

[0031] The non-aqueous organic solvent is supplemented to 100%, and the non-aqueous organic solvent is ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC) according to mass ratio EC:EMC:DEC=3:5: 2 mixed to get.

[0032] The preparation of a ...

Embodiment 2

[0044] An electrolyte solution for a silicon-carbon negative electrode lithium-ion battery, comprising electrolyte lithium salt, a non-aqueous organic solvent, a film-forming additive and a high-temperature-resistant additive, wherein the high-temperature-resistant additive is compound 1, and the quality of compound 1 accounts for 2.5% of the total mass of the electrolyte %;

[0045] The electrolyte lithium salt is LiPF 6 , LiPF 6 The mass accounts for 12.5% of the total mass of the electrolyte;

[0046] The film-forming additive is vinyl sulfate, and the quality of vinyl sulfate accounts for 2.5% of the total mass of the electrolyte;

[0047] The non-aqueous organic solvent is supplemented to 100%, and the non-aqueous organic solvent is ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC) according to mass ratio EC:EMC:DEC=3:5: 2 mixed to get.

[0048] To prepare a silicon-carbon negative electrode lithium-ion battery, the steps are the same as...

Embodiment 3

[0050] An electrolyte solution for a silicon-carbon negative electrode lithium-ion battery, comprising an electrolyte lithium salt, a non-aqueous organic solvent, a film-forming additive and a high-temperature-resistant additive, wherein the high-temperature-resistant additive is compound 1, and the quality of compound 1 accounts for 10% of the total mass of the electrolyte %;

[0051] The electrolyte lithium salt is LiPF 6 , LiPF 6 The mass accounts for 12.5% of the total mass of the electrolyte;

[0052] The film-forming additive is vinyl sulfate, and the quality of vinyl sulfate accounts for 2.5% of the total mass of the electrolyte;

[0053] The non-aqueous organic solvent is supplemented to 100%, and the non-aqueous organic solvent is ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC) according to mass ratio EC:EMC:DEC=3:5: 2 mixed to get.

[0054] To prepare a silicon-carbon negative electrode lithium-ion battery, the steps are the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com