Filter material, and preparation method and application thereof

A filter material and substrate surface technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of high binding fastness between filter material and catalyst, uniform distribution of catalyst, and good air permeability of integrated filter material, etc. , to achieve the effect of strong bonding fastness, small influence and high bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

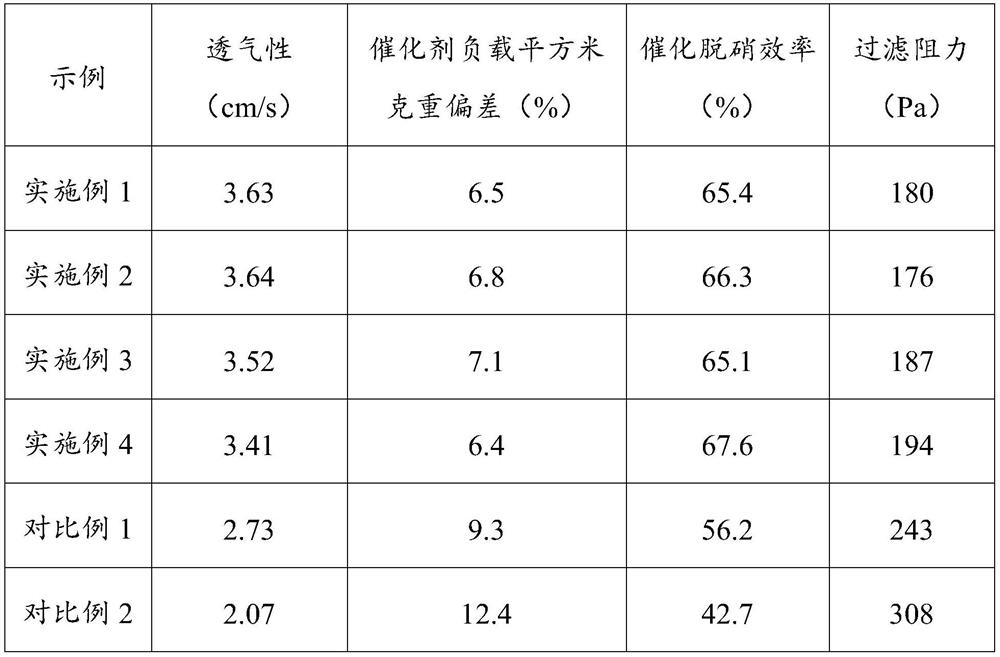

Embodiment 1

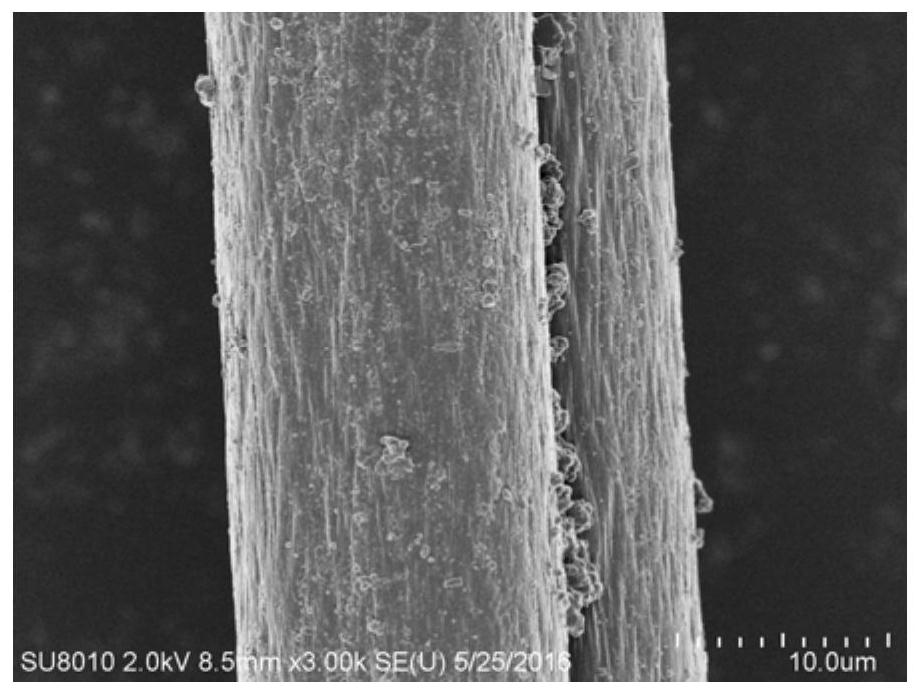

[0046] The present embodiment provides a kind of preparation method of filter material, comprises the following steps,

[0047] (1) Under the condition of 65°C, immerse the glass fiber substrate in the metal salt solution for 1 min; wherein, the metal salt solution includes titanyl sulfate, cerium nitrate and acetic acid in a molar ratio of 11:1:4.5 Manganese, the mass concentration of the metal salt solution is 15wt%.

[0048](2) Then the glass fiber base material is placed under the atmosphere of 65 ℃, and the volume concentration of 40% ammonia solution and the hydrogen peroxide solution of 30% volume concentration are sprayed successively on the surface of the glass fiber base material after immersion, and the per square meter filter In terms of material base, the spraying amount of ammonia solution is 220ml / m 2 , the spraying amount of hydrogen peroxide solution is 160ml / m 2 , After spraying, place the glass fiber substrate at 120°C to dry to remove excess water and oth...

Embodiment 2

[0052] The present embodiment provides a kind of preparation method of filter material, comprises the following steps,

[0053] (1) Under the condition of 60°C, immerse the polyimide needle felt substrate in the metal salt solution for 1.5 minutes; wherein, the metal salt solution includes sulfuric acid oxygen with a molar ratio of 11:1:4.5 Titanium, cerium nitrate and manganese acetate, the concentration of the metal salt solution is 10wt%.

[0054] (2) then the polyimide needle felt base material is placed under the atmosphere of 70 ℃, and the polyimide needle felt base material surface after dipping is sprayed successively that mass concentration is 40% urea aqueous solution and volume concentration is 12 % hydrogen peroxide solution, based on per square meter of filter substrate, the spraying amount of urea solution is 200ml / m 2 , the spraying amount of hydrogen peroxide solution is 140ml / m 2 , after spraying, put the polyimide needle-punched felt substrate at 120°C to d...

Embodiment 3

[0057] The present embodiment provides a kind of preparation method of filter material, comprises the following steps,

[0058] (1) Under the condition of 70°C, the glass fiber and polyimide composite needle felt substrate were immersed in the metal salt solution, and the immersion time was 0.8min; wherein, the metal salt solution included a molar ratio of 11:1: 4.5 titanyl sulfate, cerium nitrate and manganese acetate, the concentration of the metal salt solution is 35wt%.

[0059] (2) The composite needle felt base material is then placed in an atmosphere of 70° C., and the volume concentration of 40% ammonia solution and the volume concentration of 40% hydrogen peroxide solution are sprayed on the surface of the impregnated composite needle felt base material successively, with Calculated per square meter of filter material base material, the spraying amount of ammonia solution is 320ml / m 2 , the spraying amount of hydrogen peroxide solution is 270ml / m 2 , After spraying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com