Biosurfactant and preparation method thereof

A biosurfactant and active agent technology, which is applied in the direction of chemical instruments and methods, dissolution, etc., can solve problems such as violations of the production of biosurfactants and insufficient performance of surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

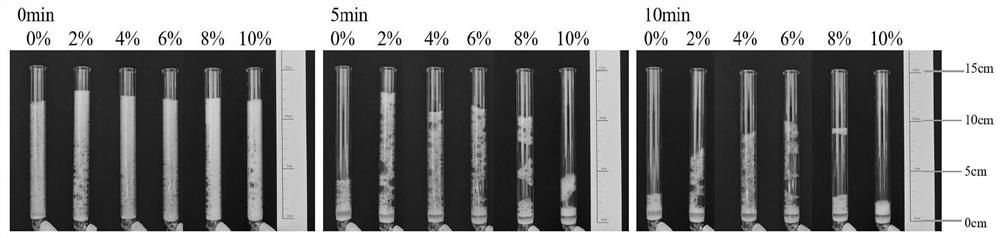

[0034] In the present invention, the degree of hydrolysis of the proteolysis product is 2%-10%. In the present invention, the preparation method of the proteolysis product preferably includes the following steps: mixing the protein to be hydrolyzed with water to obtain the product to be hydrolyzed, adding protease to the product to be hydrolyzed for enzymolysis, and sterilizing Enzymes to obtain proteolysis products.

[0035] In the present invention, before adding protease to the hydrolyzed product, it is preferred to further include preheating the hydrolyzed product to the temperature of enzymatic hydrolysis.

[0036]In the present invention, when the protease is alkaline protease and the protein to be hydrolyzed is soybean protein, the temperature of the enzymolysis is preferably 55-60°C; the time of the enzymolysis is preferably 0.01-1 h; The process of enzymolysis is preferably carried out in a water bath; during the process of enzymolysis, the pH value of the product to...

Embodiment 1

[0047] The preparation of embodiment 1 soybean protein isolate enzymatic hydrolyzate

[0048] Accurately weigh 5g of soybean protein isolate, dilute to 100mL with water, preheat in a 55°C water bath for 10min, adjust the pH to 8.0, and add 0.05g of alkaline protease for enzymatic hydrolysis. During the enzymatic hydrolysis, 1M NaOH aqueous solution was added dropwise to maintain the pH at 8.0, and the amount of lye added was recorded to determine the degree of hydrolysis. According to the predetermined degree of hydrolysis, after dropping the corresponding amount of lye, immediately inactivate the enzyme in a 95°C water bath for 15 minutes to terminate the enzymolysis reaction, and obtain the enzymolysis product after cooling down in the cold water bath. The degree of hydrolysis DH and the amount of lye added dropwise are shown in the formula I relational formula in the above-mentioned scheme.

[0049] In this embodiment, the relationship between the degree of hydrolysis of t...

Embodiment 2

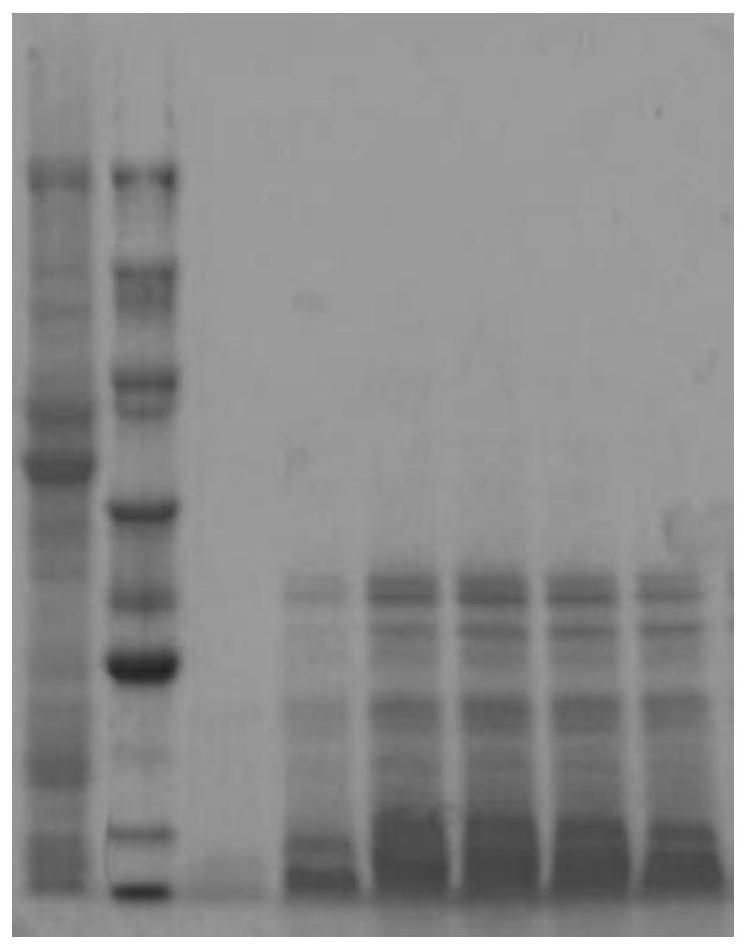

[0052] Example 2 SDS polypropylene gel electrophoresis detection of soybean protein isolate hydrolyzate

[0053] The enzymatic hydrolysis product in embodiment 1 is carried out SDS polypropylene gel electrophoresis, the result is as follows figure 1 , figure 1 The lanes from left to right in the middle are soybean protein isolate solution, marker, blank control, 2%, 4%, 6%, 8% and 10% hydrolyzed enzymatic products. Depend on figure 1 It can be seen that the particle size of soybean protein isolate is significantly smaller after being enzymatically hydrolyzed, and has a faster migration rate in the gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com