Phenol wastewater treatment method

A treatment method, phenol technology, applied in water/sewage treatment, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of low iron ion circulation efficiency, waste post-treatment efficiency, low utilization rate of hydrogen peroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In the preparation of the described zerovalent iron sulfide, the present invention first prepares a compound containing CH 3 COOH and CH 3 COONa buffer solution, and removing oxygen in the buffer solution to obtain a deoxidizing solution.

[0051] In certain embodiments of the present invention, in the buffer solution, CH 3 The concentration of COONa is 1.00~2.50mol / L, CH 3 The concentration of COOH is 0.10 to 0.16 mol / L. In certain embodiments, in the buffer solution, CH 3 The concentration of COONa is 1.2mol / L, CH 3 The concentration of COOH was 0.10 mol / L.

[0052] In certain embodiments of the present invention, the pH of the buffer solution is 5.5-6.5. In certain embodiments, the pH of the buffer solution is 6.0.

[0053] The present invention has no special limitation on the preparation method of the buffer solution, and the preparation method of the buffer solution well known to those skilled in the art can be used for preparation.

[0054] In some embodime...

Embodiment 1

[0091] (1) Preparation of oxygen removal solution: Add 200mL deionized water into a three-necked flask, add 20.00g (243mmol) of anhydrous CH 3 COONa was stirred until it was completely dissolved, and then 1.20 mL (20 mmol) of CH 3 COOH to obtain a buffer solution (pH value is 6.0), and nitrogen gas was passed into the buffer solution for 30 minutes to eliminate oxygen in the buffer solution to obtain a deoxygenated solution.

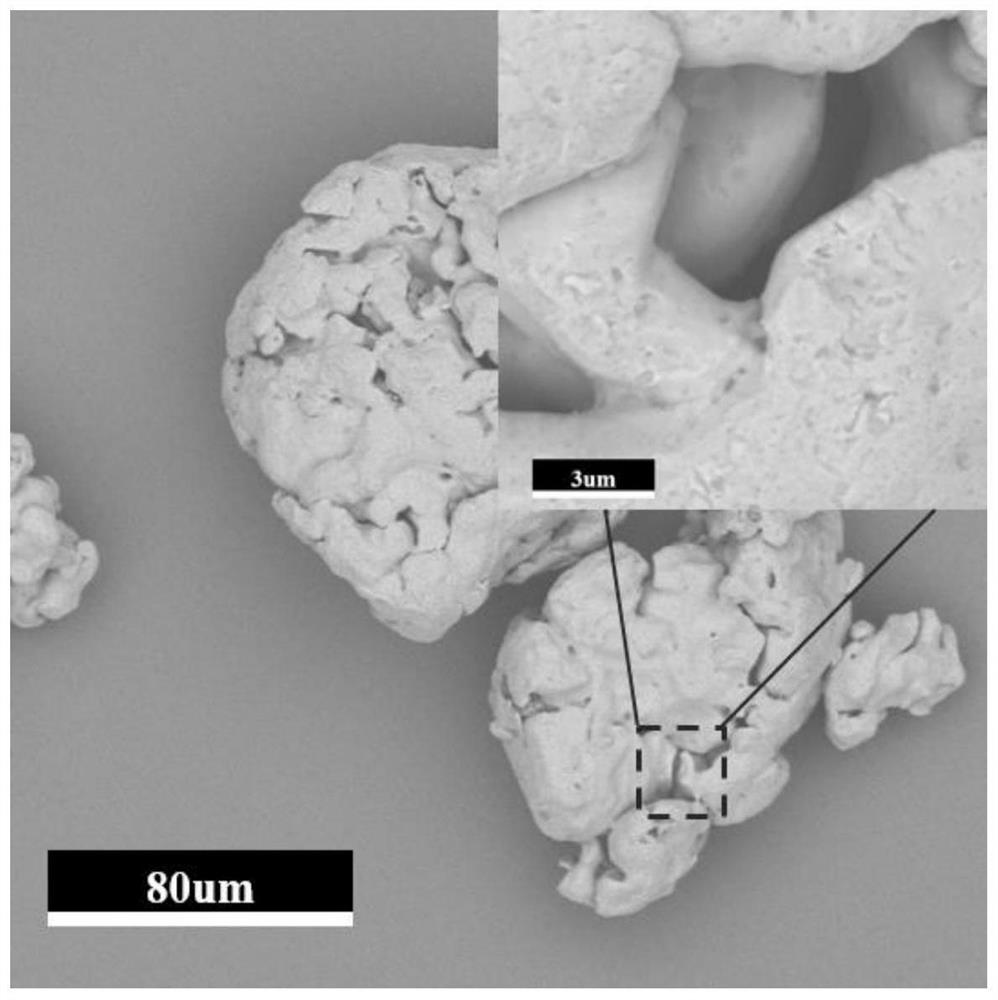

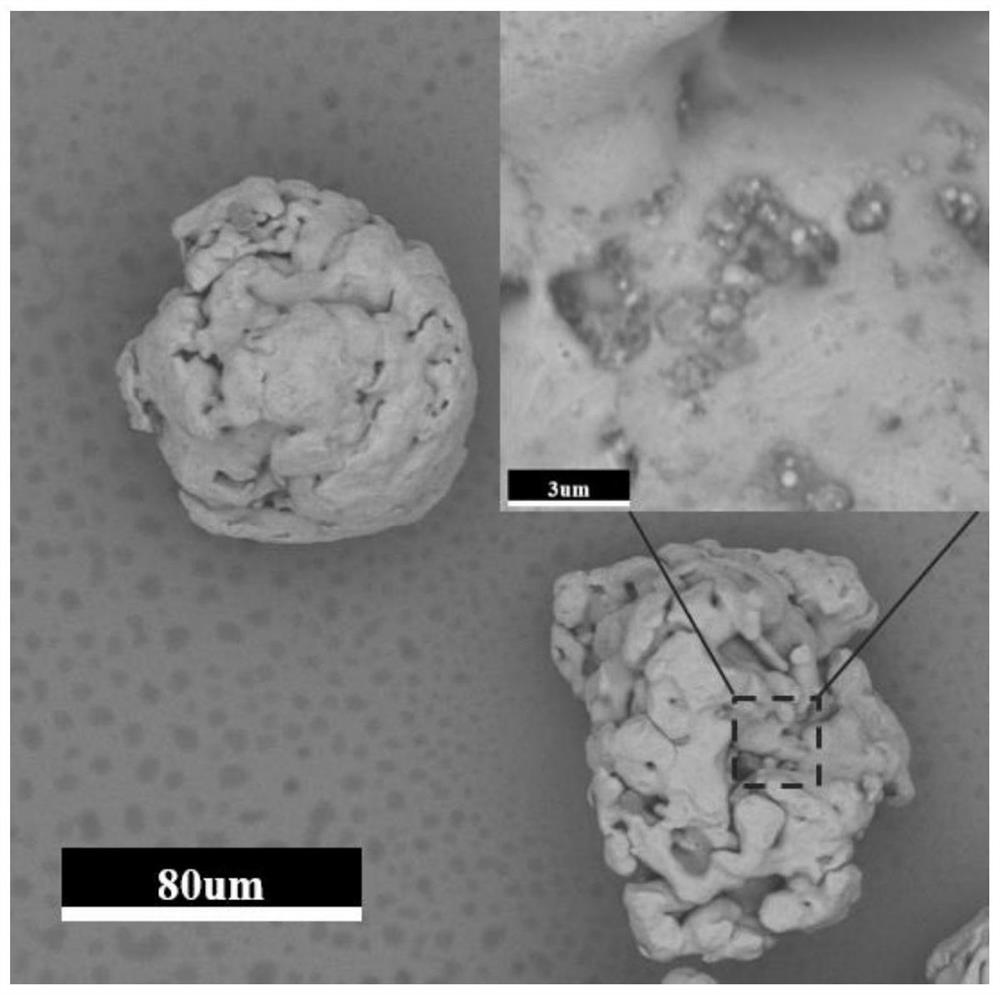

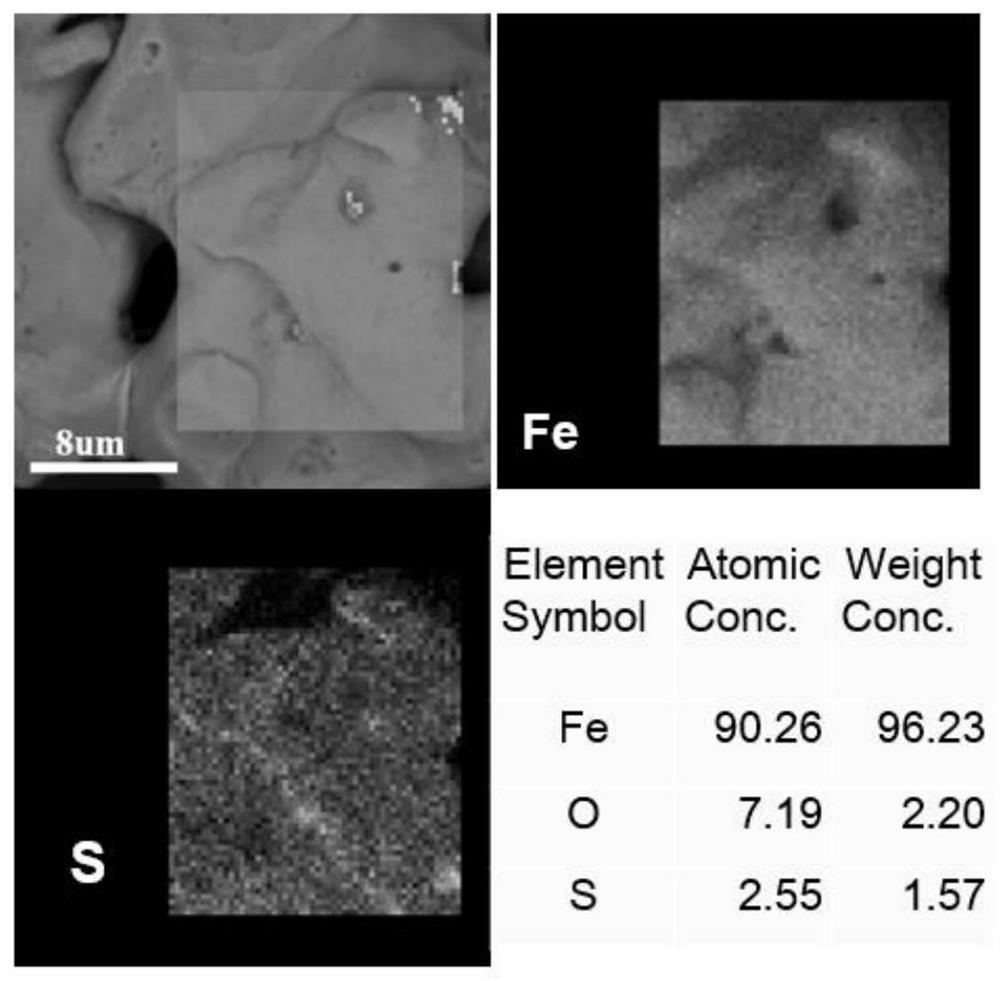

[0092] (2) Preparation of catalyst: 8.0g iron powder is added in the described deaeration solution, feed nitrogen 30min in the solution obtained, add 3.0g sodium sulfide nonahydrate and 0.1g sulfur powder, continue feeding nitrogen, in The reaction was performed under mechanical stirring at 20° C. for 4 h at a rotational speed of 500 rpm. At the end of the reaction, the pH of the solution became 10.5.

[0093] (3) Washing and drying of the catalyst: transfer the reacted solid-liquid mixture into a centrifuge tube, centrifuge for 5min (rotating speed is...

Embodiment 2

[0101] (1) Preparation of deoxygenation solution: add 200 mL of deionized water into a three-necked bottle, add 30.00 g of anhydrous CH 3 COONa was stirred until completely dissolved, and then 1.40 mL of CH was added. 3 COOH to obtain a buffer solution (pH value is 6.0), and nitrogen gas was introduced into the buffer solution for 30 min to remove oxygen in the buffer solution to obtain a deoxygenated solution.

[0102] (2) preparation of catalyst: 10g of iron powder was added to the deoxidizing solution, nitrogen was introduced into the solution obtained for 30min, 4.0g of sodium sulfide nonahydrate was added, nitrogen was continuously introduced, and the rotating speed was 500rpm for 22 minutes. The reaction was mechanically stirred for 4h. At the end of the reaction, the pH of the solution became 11.0.

[0103] (3) washing and drying of catalyst: transfer the reacted solid-liquid mixture into a centrifuge tube, centrifuge for 5min (rotating speed is 4000rpm), remove super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com