Transparent silicon dioxide antireflection film coating process

A technology of silicon dioxide and anti-reflection coating, applied in the direction of coating, can solve problems such as poor coating effect and poor optical performance, achieve good optical and mechanical properties, improve connection strength, and increase the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

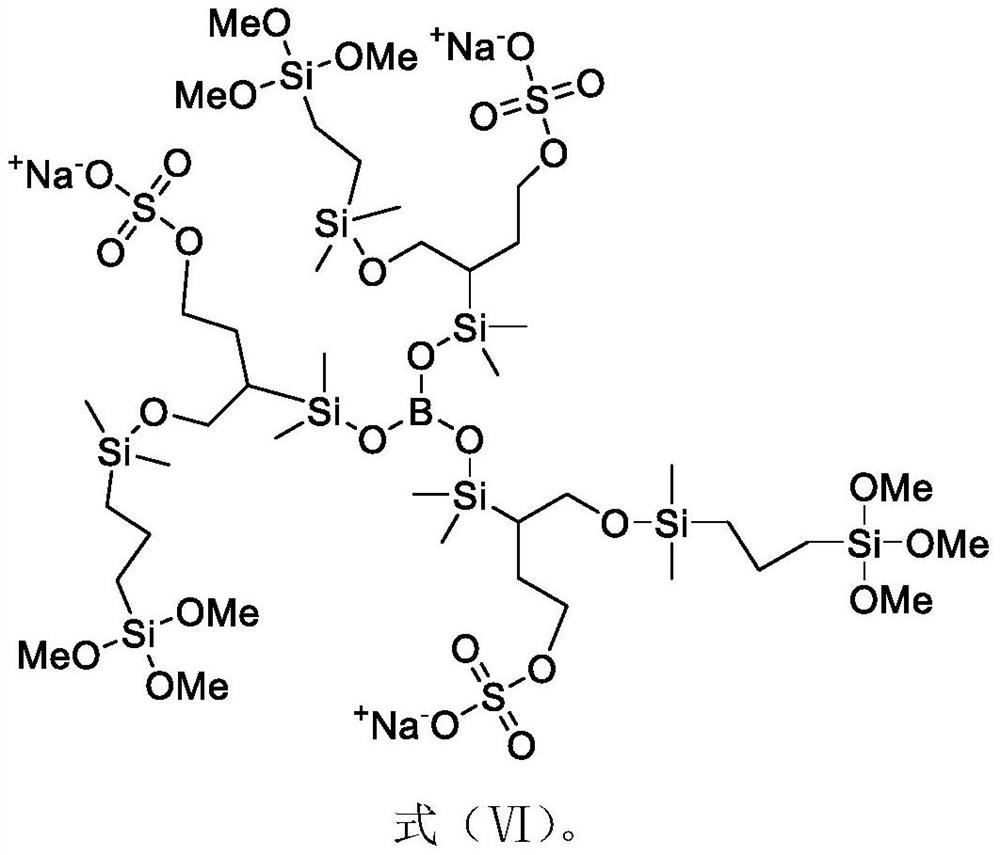

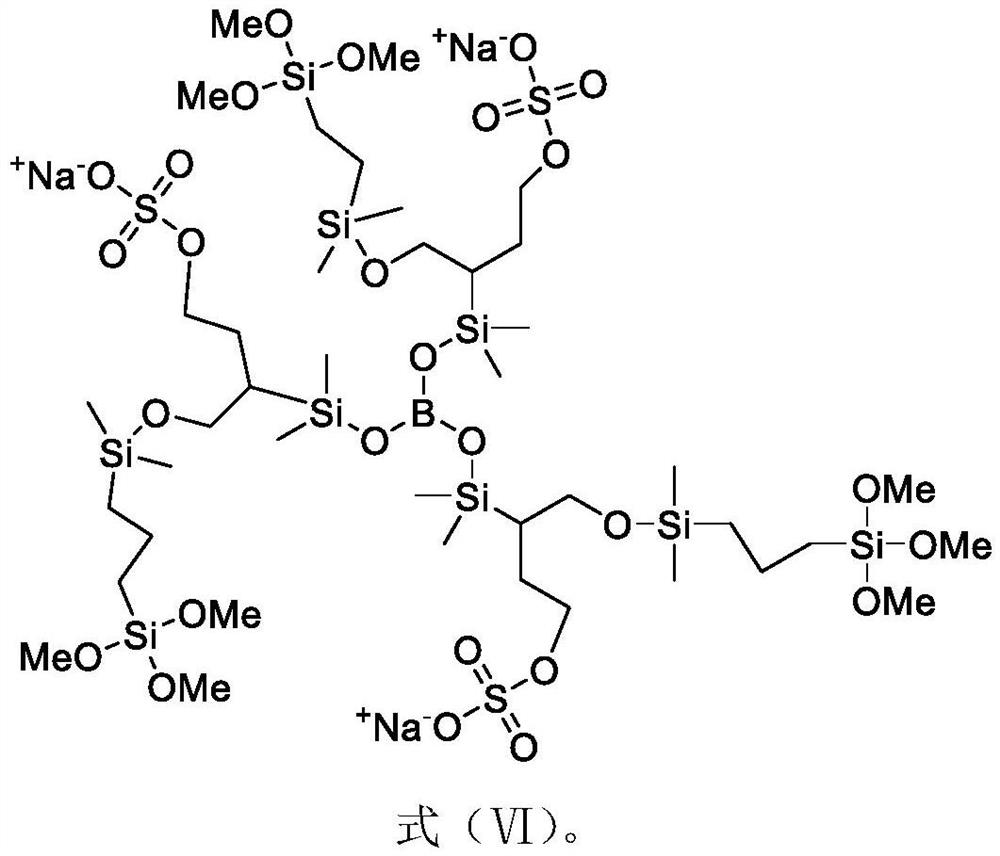

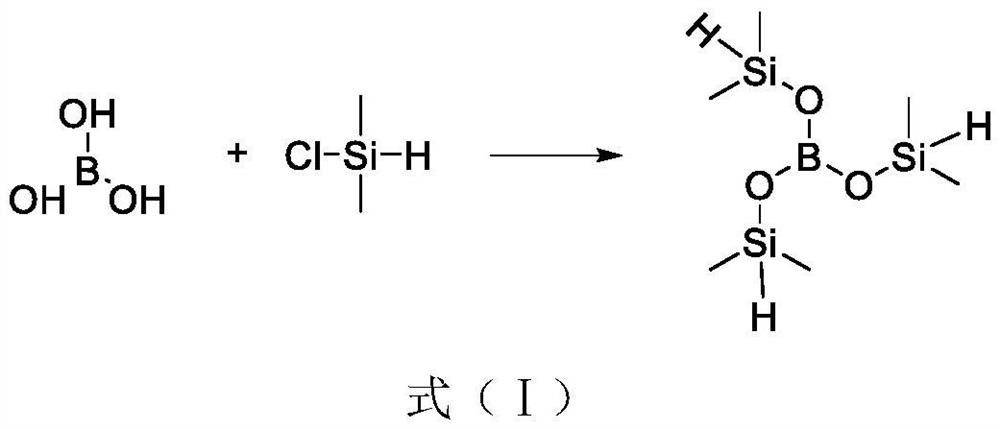

[0037] The preparation method of hyperbranched organosilicon prepolymer among the present invention is as follows:

[0038] (S.1) Under the protection of nitrogen, take 0.1mol of boric acid and 0.3mol of triethylamine dissolved in 100ml of dichloromethane and add them to the reaction kettle, and add 0.3mol of dimethylchlorosilane dropwise to it, and stir for 2 hours at -10°C Finally, after washing the reaction solution with water, the solvent was rotated to obtain compound A;

[0039] (S.2) Under nitrogen protection, add 0.1mol of compound A, 0.3mol of 2-butene-1,4-diol, 100ml of toluene and a catalytic amount of Castel catalyst into the reaction kettle and stir for 3h at 85°C , add 0.1g of activated carbon and stir for 10 minutes, filter and spin evaporate the solvent to obtain compound B;

[0040] (S.3) Under the protection of nitrogen, dissolve 0.1 mol of compound B in an organic solvent, and dropwise add 0.1 mol of chlorosulfonic acid to it, stir and react at 0°C for 2 ho...

Embodiment 1

[0044] A transparent silicon dioxide anti-reflection film coating process, comprising the following steps:

[0045] (S.1) Immerse the glass in an aqueous solution of sodium hydroxide with a pH value of 11.5 for 600 seconds, and corrode the glass surface, thereby forming micro-nano holes with a diameter of 50-500 nm and a depth of 50-100 nm on the glass surface;

[0046] (S.2) Dissolve the hyperbranched silicone prepolymer in acidic ethanol aqueous solution with a pH value of 4.5, wherein the mass of the hyperbranched silicone prepolymer, ethanol and water is 10:45:20, and prepare into a mixed solution, stirred and reacted at 50°C for 1 hour, and aged for 18 hours to obtain a transparent silica sol;

[0047] (S.3) Immerse the corroded glass in step (1) in transparent silica sol, form a layer of silicon-containing film on its surface by pulling method, let it stand for a certain period of time, and the pulling speed is 100mm / min. Stand still for 60s after pulling;

[0048] (S....

Embodiment 2

[0051] A transparent silicon dioxide anti-reflection film coating process, comprising the following steps:

[0052] (S.1) Immerse the glass in an aqueous solution of sodium hydroxide with a pH value of 13 for 60 seconds to corrode the glass surface, thereby forming micro-nano holes with a diameter of 50-500 nm and a depth of 50-100 nm on the glass surface;

[0053] (S.2) Dissolve the hyperbranched silicone prepolymer in an aqueous acidic ethanol solution with a pH value of 6, wherein the mass between the hyperbranched silicone prepolymer, ethanol and water is 30:60:40, and prepare into a mixed solution, stirred and reacted at 70°C for 5 hours, and aged for 48 hours to obtain a transparent silica sol;

[0054] (S.3) Immerse the corroded glass in step (1) in transparent silica sol, form a layer of silicon-containing film on its surface by pulling method, let it stand for a certain period of time, the pulling speed is 250mm / min, static The setting time is 10s;

[0055] (S.4) He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com