Synthesis method of low-cost long-carbon-chain cationic quaternary ammonium salt

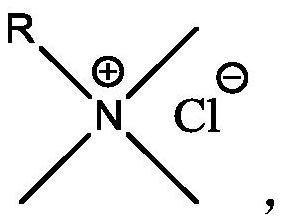

A cationic quaternary ammonium salt, long carbon chain technology, applied in the field of synthesizing cationic quaternary ammonium salts, can solve the problems of high reaction temperature (190-220 ℃, large price fluctuations of raw material fatty alcohols, difficult to control side reactions, etc., to achieve disinfection. The effect of good bactericidal and emulsifying properties, excellent solubility, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of quaternization catalyst:

[0047] Add 50 g support CuO to 100 mL NiSO 4 solution (which contains 2.37g NiSO 4 ·6H 2 O), after stirring for 2h, add 100mL H 2 PdCl 4 solution (which contains 1.13g H 2 PdCl 4 ), stirred overnight at 60 °C, filtered the solid product and dried at 80 °C for 20 h to obtain a Pd-Ni / CuO catalyst.

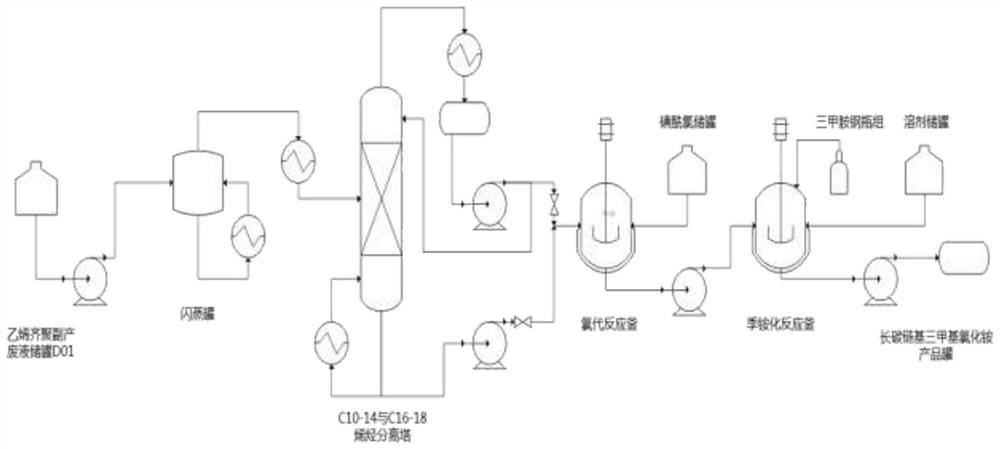

[0048] Preparation of cationic quaternary ammonium salt (using ethylene oligomerization process by-product as olefin source):

[0049] (1) Separation of olefins

[0050] The octene-1 refining column waste liquid storage tank of the ethylene oligomerization process of the POE unit is transported to the flash tank through the raw material pump. The operating conditions of the flash tank are: temperature 200°C, pressure 1.0KPa. C10-18 olefins are obtained by separation, and impurities such as oligomerization catalysts and ligands are removed. The C10-18 olefin stream enters the olefin separation tower, collects C10-14 olefins at ...

Embodiment 2

[0062] Preparation of quaternization catalyst:

[0063] Add 50 g of support CuO to 100 mL of FeCl 3 solution (containing 0.51g FeCl 3 ), stirred for 2h and then added 100mLH 2 PdCl 4 solution (containing 3.13g H 2 PdCl 4 ), stirred overnight at 60 °C, filtered the solid product and dried at 80 °C for 20 h to obtain a Pd-Fe / CuO catalyst.

[0064] Preparation of cationic quaternary ammonium salt: (using trimeric isobutene as olefin source)

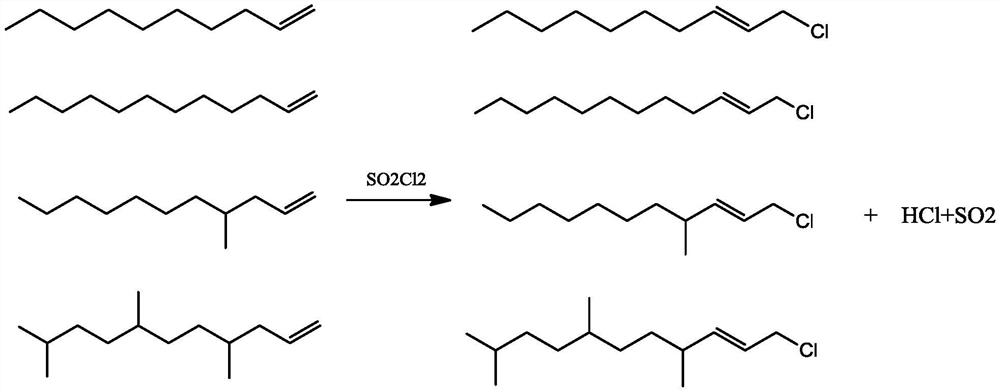

[0065] (1) Chlorination reaction

[0066] The chlorination reaction adopts a semi-continuous drop reaction process. Triisobutene and sulfonyl chloride enter the chlorination reactor in the form of dropwise addition, the molar ratio of the feed amount is 0.3:1, and the temperature of the reactor is 60°C. After 1 / 2 volume of the kettle, the dropwise addition was stopped, and the reaction was carried out at a constant temperature for 1.5 hours. Normal pressure is maintained during the reaction process, and the tail gas is pumped by the ...

Embodiment 3

[0073] Preparation of quaternization catalyst:

[0074] Add 50 g of support CuO to 100 mL of H 2 PtCl 6 ·6H 2 O solution (containing 1.91g H 2 PtCl 6 ·6H 2 O), after stirring for 2h, add 100mL H 2 PdCl 4 solution (containing 1.84g H 2 PdCl 4 ), stirred overnight at 60 °C, filtered the solid product and dried at 80 °C for 20 h to obtain a Pd-Pt / CuO catalyst.

[0075] Preparation of cationic quaternary ammonium salt: (using tetrapropylene as olefin source)

[0076] (1) Chlorination reaction

[0077] The chlorination reaction adopts a semi-continuous dropwise reaction process. Tetrapropylene and sulfonyl chloride enter the chlorination reactor in the form of dropwise addition, the molar ratio of the feed amount is 0.5:1, and the temperature of the reactor is 50°C. After 1 / 2 volume of the reaction kettle, the dropwise addition was stopped, and the reaction was performed at a constant temperature for 3.0 hours. Normal pressure is maintained during the reaction process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com