Preparation method of beryllium-aluminum alloy surface composite reinforced modified layer

A beryllium-aluminum alloy and surface compounding technology is applied in the field of preparation of a beryllium-aluminum alloy surface composite strengthening and modified layer, which can solve the problems of mismatched CTE parameters of the matrix, large differences in phase electrochemical properties, and low hardness/strength, etc. Difficulty and heating power advantages, reduce usage, and ensure the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

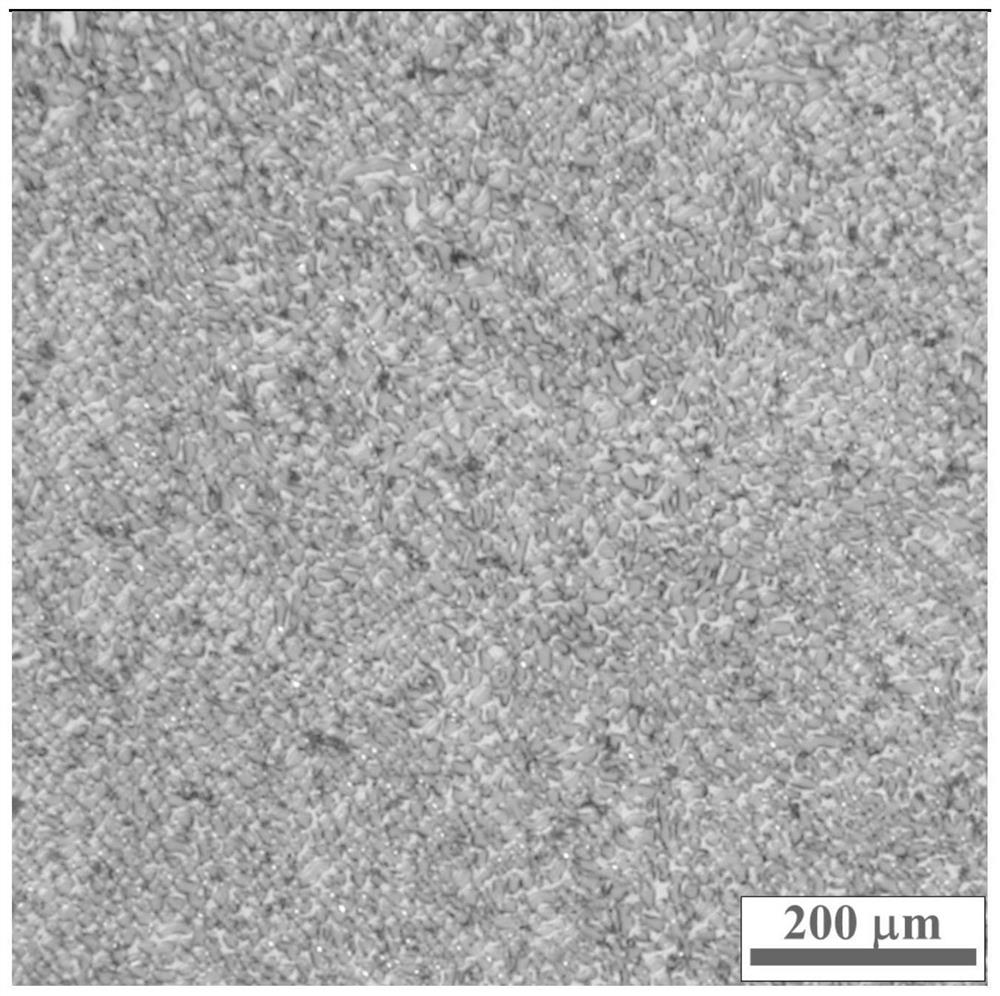

[0038] A method for preparing a beryllium-aluminum alloy surface composite strengthened modified layer, comprising the steps of:

[0039](1) Aluminum oxide powder and beryllium oxide powder with an average particle diameter of about 100 microns, aluminum oxide powder and beryllium oxide powder with an average particle diameter of about 100 nanometers, 20% of aluminum oxide powder, 15% of nano beryllium oxide powder, and the rest being aluminum powder Prepare in parts by weight, carry out dry ball milling and mixing in high-purity argon, the balls used in the ball milling are corundum, the weight ratio of the balls and the composite mixed powder is controlled at 1:1, the ball milling time is 2 hours, and then in high-purity argon Take out the premixed powder in the air and let it stand for later use;

[0040] (2) Grinding and polishing the surface of the beryllium aluminum alloy to be treated, ultrasonically cleaning it with analytical pure anhydrous ethanol and deionized water...

Embodiment 2

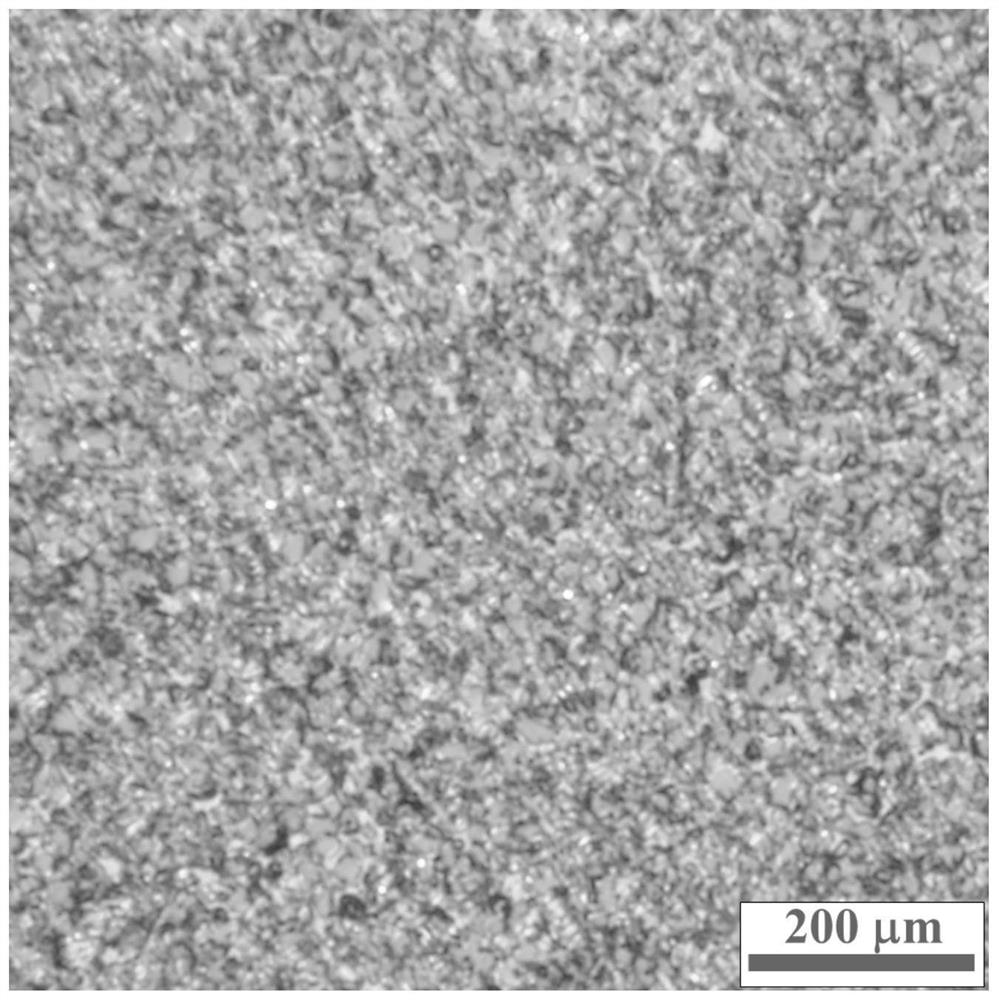

[0045] A method for preparing a beryllium-aluminum alloy surface composite strengthened modified layer, comprising the steps of:

[0046] (1) Aluminum oxide powder and beryllium oxide powder with an average particle diameter of about 150 microns, aluminum oxide powder and beryllium oxide powder with an average particle diameter of about 200 nanometers, 25% of aluminum oxide powder, 20% of nano beryllium oxide powder, and the rest being aluminum powder Prepare in parts by weight, carry out dry ball milling and mixing in high-purity argon, the balls used in ball milling are corundum, the weight ratio of balls and composite mixed powder is controlled at 1:0.8, the ball milling time is 3 hours, and then in high-purity argon Take out the premixed powder in the air and let it stand for later use;

[0047] (2) Grinding and polishing the surface of the beryllium aluminum alloy to be treated, ultrasonically cleaning it with analytical pure anhydrous ethanol and deionized water successi...

Embodiment 3

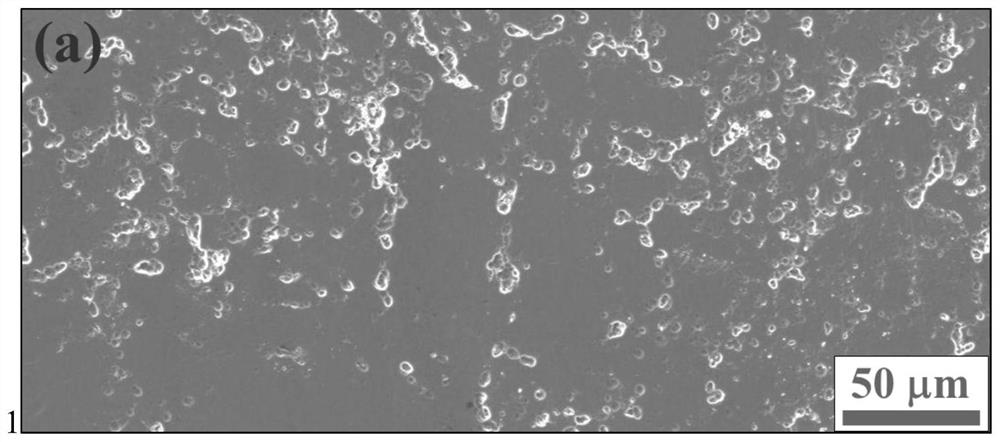

[0052] A method for preparing a beryllium-aluminum alloy surface composite strengthened modified layer, comprising the steps of:

[0053] 1) Aluminum oxide powder and beryllium oxide powder with an average particle size of about 30 microns, aluminum oxide powder and beryllium oxide powder with an average particle size of about 20 nanometers, according to the weight of aluminum oxide powder 30%, nano beryllium oxide powder 30%, and the rest being the weight of metal aluminum powder Parts preparation, dry ball milling and mixing in high-purity argon, the balls used in the ball milling are corundum, the weight ratio of the balls and the composite mixed powder is controlled at 1:1.2, the ball milling time is 5 hours, and then in high-purity argon Take out the pre-mixed powder and let it stand for later use;

[0054] (2) Grinding and polishing the surface of the beryllium aluminum alloy to be treated, ultrasonically cleaning it with analytical pure anhydrous ethanol and deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com