Perfluoropolyether carboxylic acid compound and preparation method thereof

A technology of perfluoropolyether carboxylic acid and perfluoropolyether, which is applied in the field of polymer compound synthesis, can solve the problems of cumbersome perfluoropolyether carboxylic acid route, discomfort for experimenters, and difficulty in removing potassium salt, and saves the cost of reagents. , the effect of high reaction yield and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

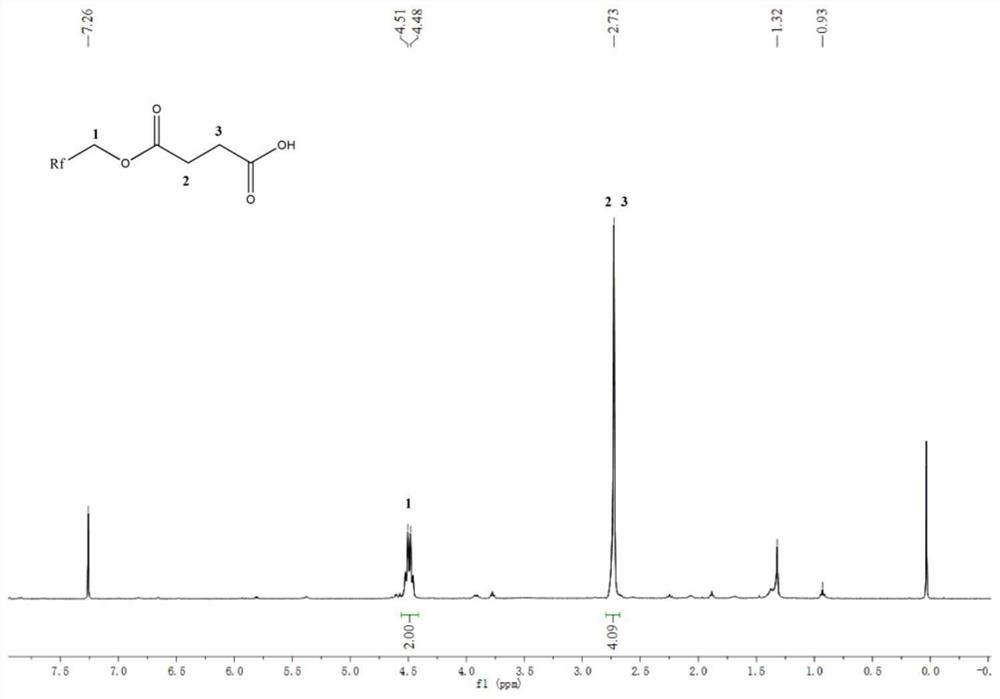

[0048] Add 10g (2.86mmol) to the 100mL three-neck flask equipped with stirring and the average composition is 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 CH 2 OH perfluoropolyether alcohol (the sum of p and q is 36, the number average molecular weight is 3500, produced by SOLVAY company), 15mL m-ditrifluorotoluene, 0.43g (4.29mmol, 1.5equ) of succinic anhydride, 0.05g ( 0.5wt% dimethylaminopyridine in perfluoropolyether alcohol), heated up to 40°C and stirred for 5 hours, then extracted with water and distilled under reduced pressure to obtain 10.08g of a colorless and transparent product with a yield of 98%. Ether carboxylic acid compound (A 1 ) CF 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 CH 2 OCOCH 2 CH 2 COOH, the reaction formula is as follows.

[0049]

[0050] where Rf is CF 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 -.

Embodiment 2

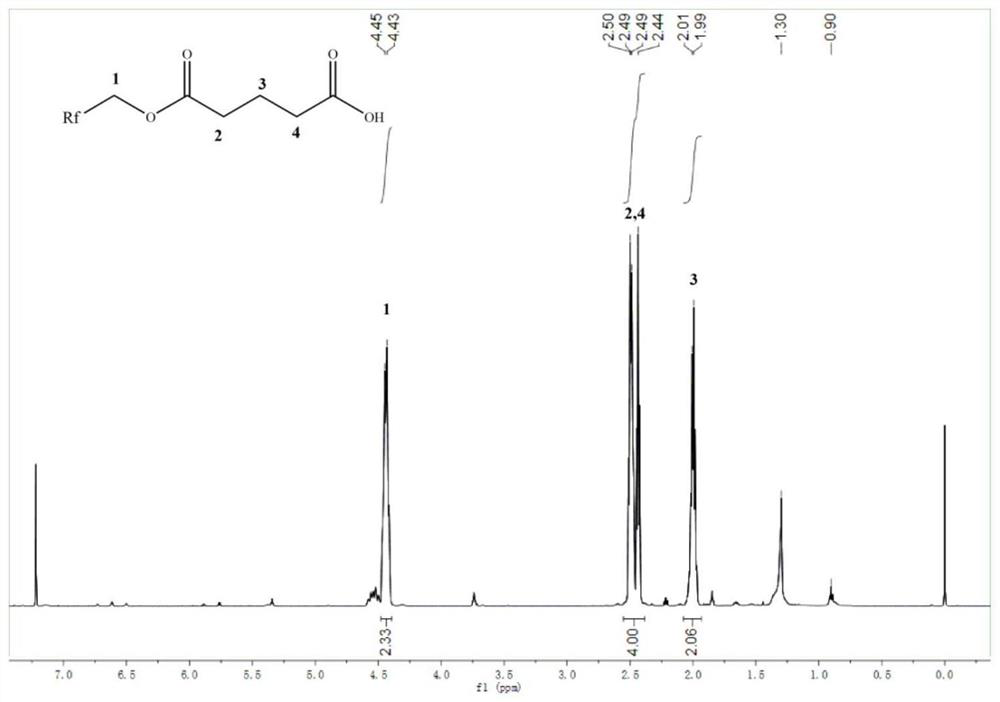

[0052] Add 10g (2.03mmol) average composition to CF in a 100mL three-neck flask equipped with stirring 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 CH 2 OH perfluoropolyether alcohol (the sum of p and q is 49, the number average molecular weight is 4930, produced by SOLVAY company), 15mL m-ditrifluorotoluene, 0.69g (6.09mmol, 3equ) of glutaric anhydride, 0.2g (2wt % N,N-diisopropylethylamine in perfluoropolyether alcohol), heated to 60°C under reflux and stirred for 4h, and obtained 10.03g of a colorless and transparent product through water extraction and vacuum distillation, with a yield of 98%. That is perfluoropolyether carboxylic acid compound (A 2 ) CF 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 CH 2 OCOCH 2 CH 2 CH 2 COOH, the reaction formula is as follows.

[0053]

[0054] where Rf is CF 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 -.

Embodiment 3

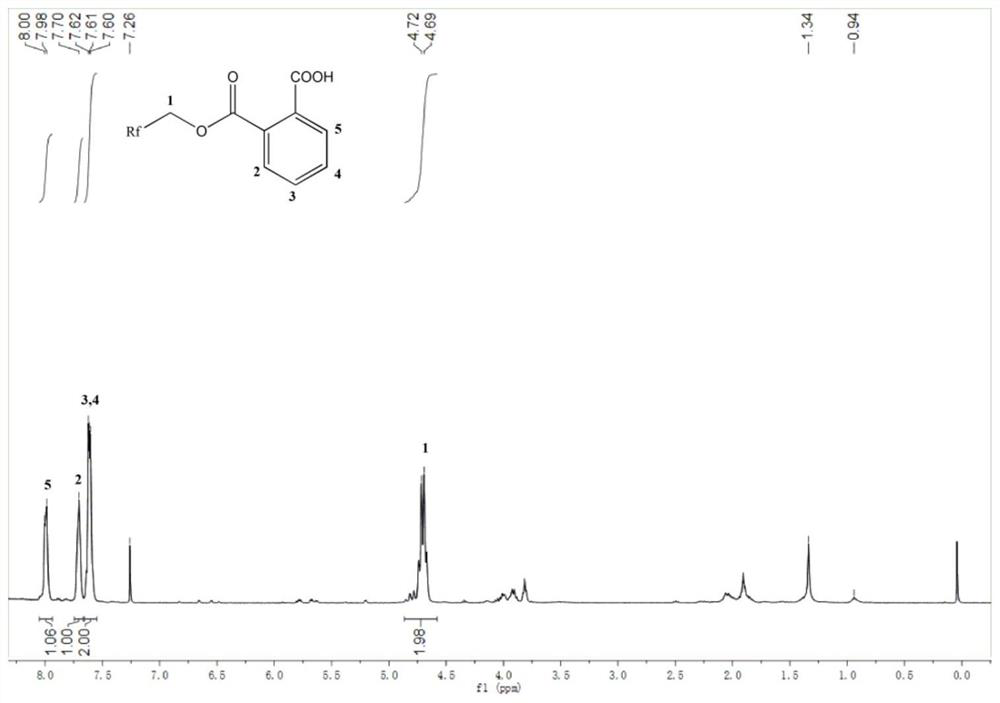

[0056] Add 10g (2.86mmol) average composition to CF in a 100mL three-necked flask equipped with stirring 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 CH 2 OH perfluoropolyether alcohol (the sum of p and q is 36, the number average molecular weight is 3500, produced by SOLVAY company), 25mL m-ditrifluorotoluene, 2.12g (14.29mmol, 5equ) of phthalic anhydride, 0.5g (5wt% in perfluoropolyether alcohol) of dimethylaminopyridine, heated to 80 ° C and stirred for 3 hours, obtained 10.18 g of a colorless and transparent product through water extraction and vacuum distillation, with a yield of 99%, which is perfluoropolyether alcohol. Ether carboxylic acid compound (A 3 ), CF 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 CH 2 OCOC 6 h 4 COOH, the reaction formula is as follows.

[0057]

[0058] where Rf is CF 3 (OCF 2 CF 2 ) p (OCF 2 ) q OCF 2 -

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com