Method for analyzing small-size conductive and non-conductive materials by applying glow discharge mass spectrometry

A technique of glow discharge mass spectrometry and non-conductive materials, which is applied to the analysis of materials, material analysis by electromagnetic means, and preparation of test samples. It can solve problems such as poor discharge stability, complicated pretreatment, and easy pollution, and achieve Good discharge stability, simple pre-treatment, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

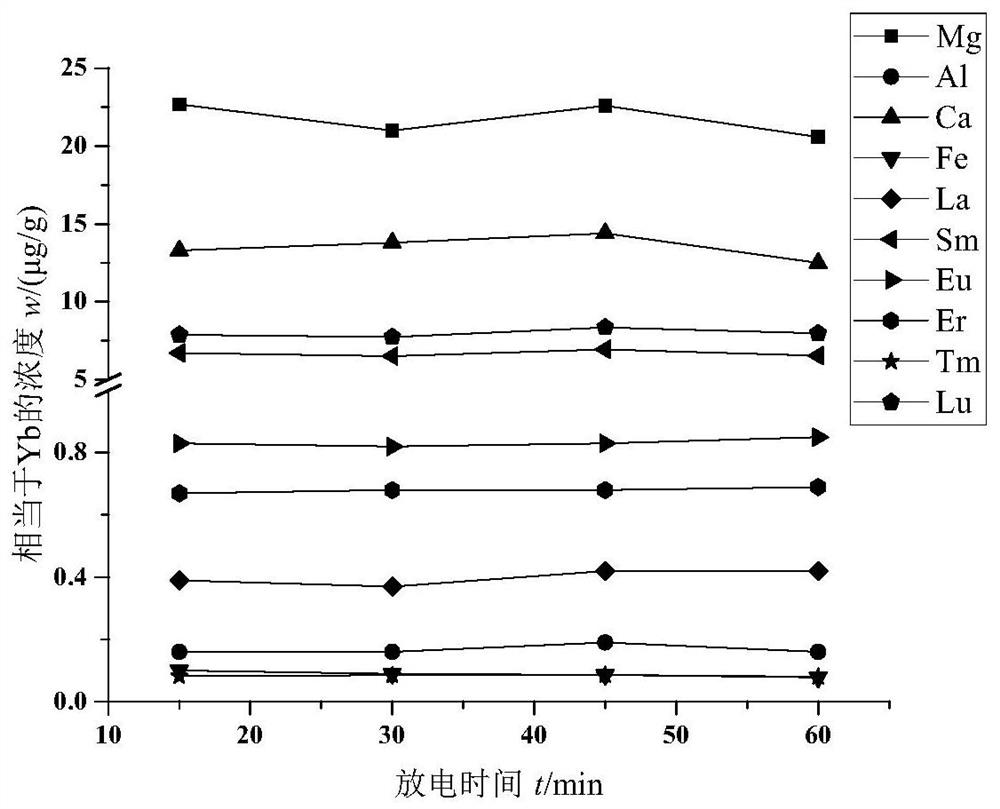

[0045] Nitric acid (HNO 3 ) and ultrapure water, ultrasonically cleaned, then ultrasonically twice in ultrapure water, and finally washed with ethanol and dried in the air. Put the graphite powder in an aluminum cup with a height of about 5mm and a diameter of 25mm. The thickness of the graphite powder is about 3-4mm. Gently shake the aluminum cup to make the surface of the graphite powder smooth. Use tweezers to pick up several pieces of scrap metal ytterbium and place them on the graphite powder. The diameter covered by scrap metal ytterbium is ≥ 10mm, and the thickness is the thickness of a layer of scrap metal ytterbium. Compress under ~10MPa. Put the pressed sample into the dc-GDMS chip sample cell for analysis, the discharge voltage is 1.2kV, the discharge current is 1.5mA, the argon gas flow rate is 350mL / min, the content of typical elements in different time periods is detected, and the inductively coupled plasma Method comparison by mass spectrometry (ICP-MS).

[0...

Embodiment 2

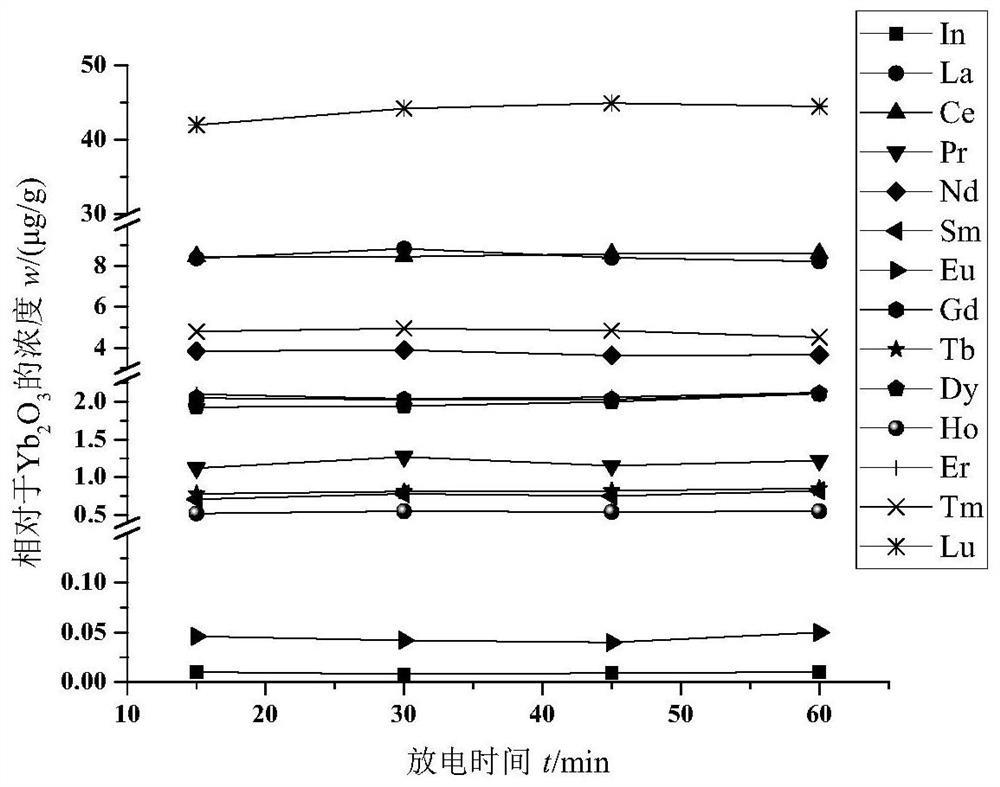

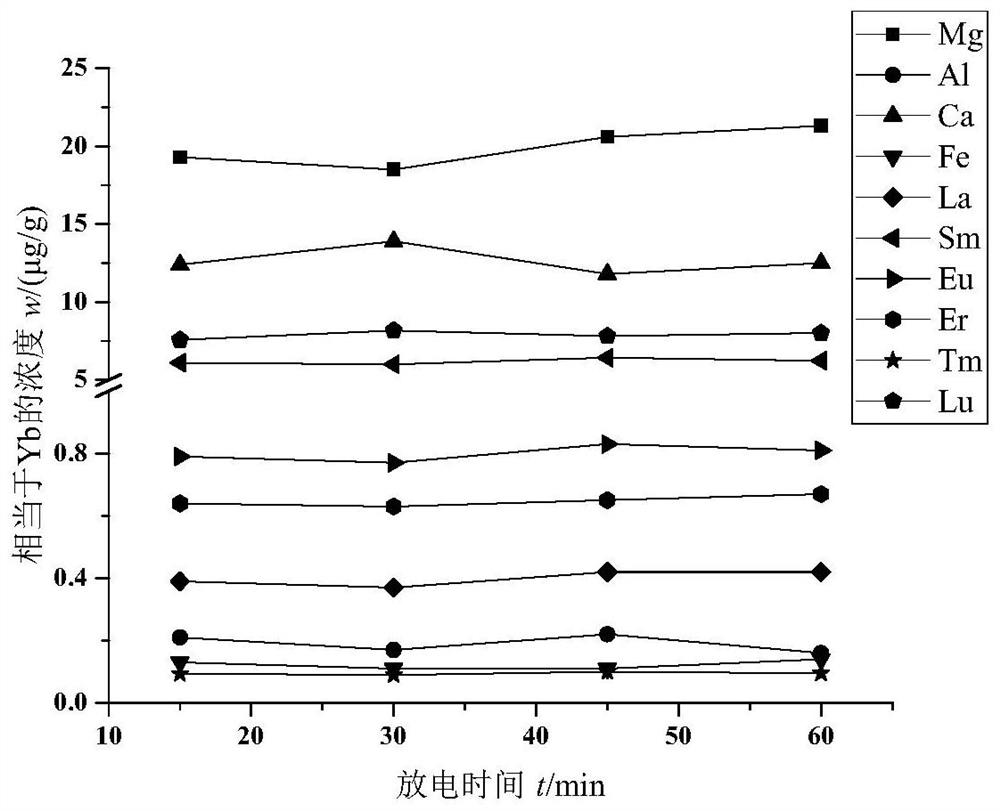

[0054] Put the graphite powder in an aluminum cup with a height of about 5mm and a diameter of 25mm. The thickness of the graphite powder is 3-4mm. Gently shake the aluminum cup to make the surface of the graphite powder smooth. Take an appropriate amount of ytterbium oxide powder and place it on the graphite powder. The diameter covered by the ytterbium oxide powder is 5mm, and the thickness is 0.5mm. The surface is covered with several layers of sulfuric acid paper, and pressed into a sheet under a pressure of 5-10MPa in a tablet press. The samples were put into the dc-GDMS flake sample cell for analysis, the discharge voltage was 1.3kV, the discharge current was 1.5mA, and the flow rate of argon gas was 400mL / min. ICP-MS) for method comparison.

[0055] The discharge stability of the method of the present invention is characterized by the contents of typical elements detected in different time periods. The relative standard deviation (RSD%) of the typical element content d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com