Preparation method of europium-activated aluminate blue fluorescent powder

A technology of blue fluorescent powder and aluminate, which is applied in chemical instruments and methods, luminescent materials, sustainable manufacturing/processing, etc., can solve the problems of complex process, inability to obtain particle size, small distribution, etc., and achieve particle size Uniform distribution, good for screen coating and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

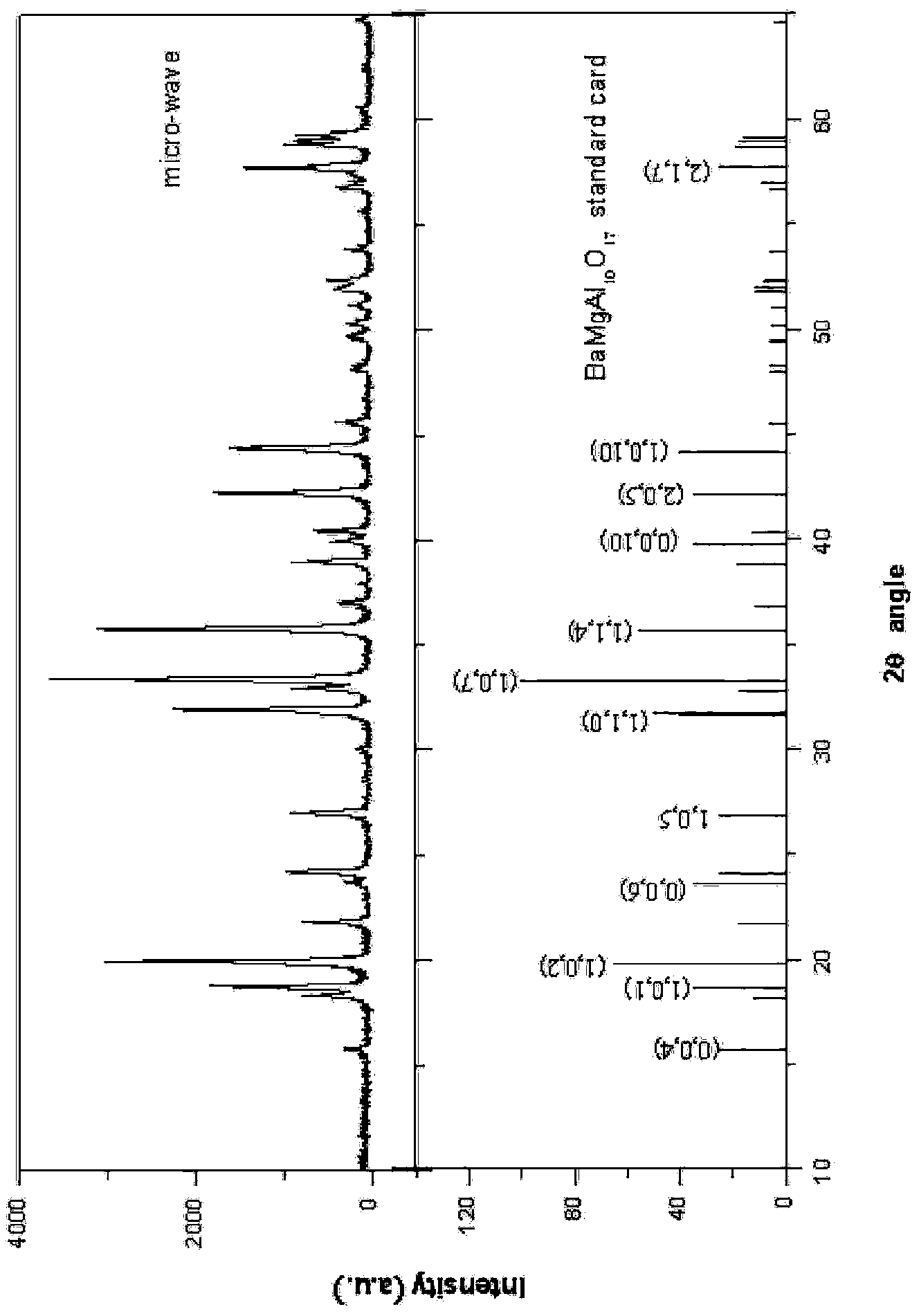

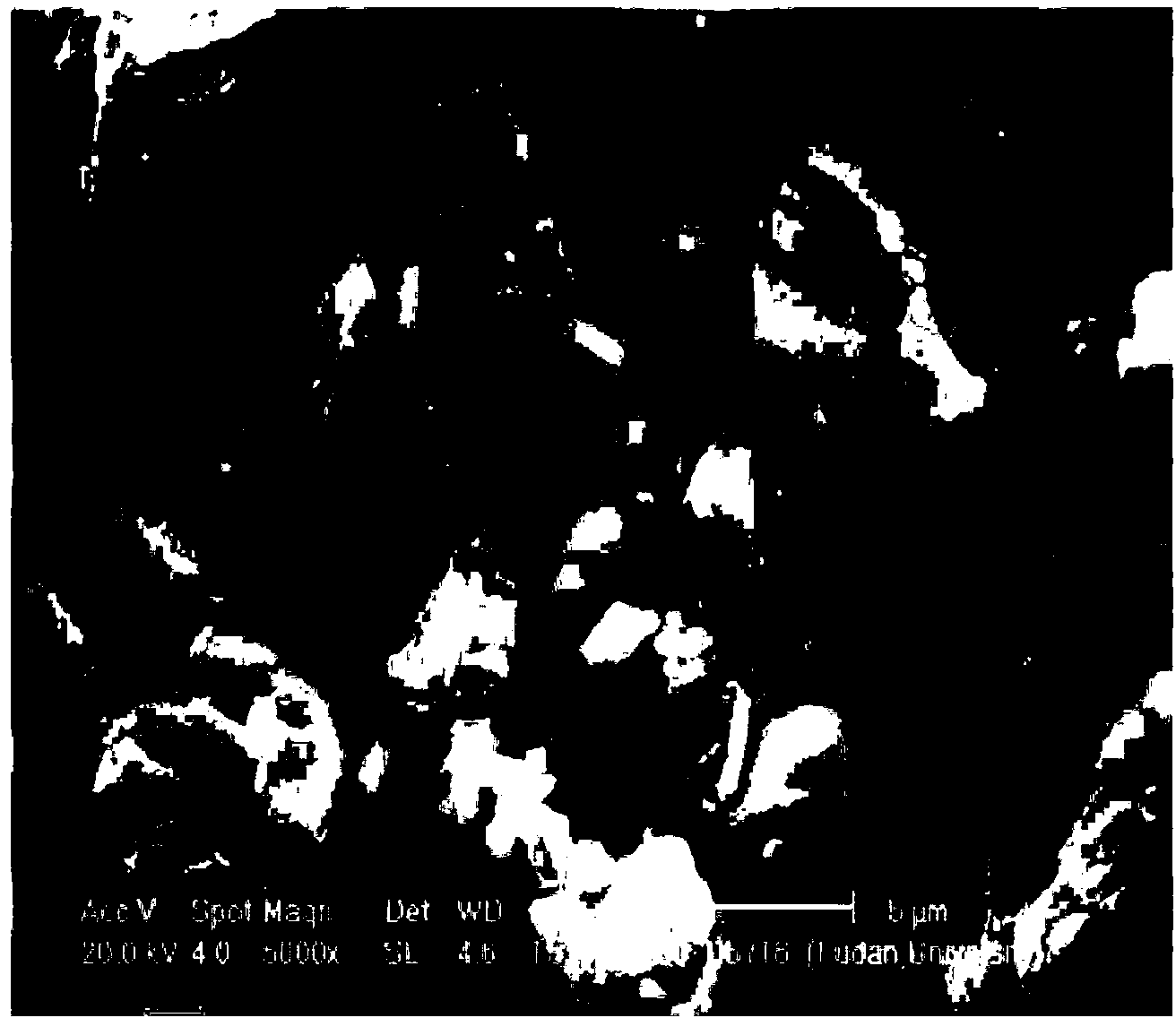

[0022] Example 1: Ba 0.9 MgAl 10 o 17 :Eu 0.1

[0023] 1) Take Ba(NO 3 ) 2 Solution (0.4mol / L) 90ml, Al(NO 3 ) 3 Solution (1mol / L) 400ml, Mg(NO 3 ) 2 Solution (0.4mol / L) 100ml, Eu(N0 3 ) 3 20ml of the solution (0.2mol / L) was mixed evenly to obtain a mixed solution;

[0024] 2) Using ammonia water to adjust the pH of the mixed solution to 2 to obtain a precursor solution;

[0025] 3) Import the precursor mixed solution into the ultrasonic nebulizer, send it into the reaction furnace through the carrier gas, control the temperature of the reaction furnace to 800°C, and react for 5 minutes to obtain the precursor;

[0026] 4) Place the precursor in a microwave reaction furnace, the temperature of the microwave reaction furnace is 1000°C, and place it in a reducing atmosphere in the microwave reaction furnace (N 2 :H 2 =9:1) for 25 minutes;

[0027] 5) Reduce to room temperature in a reducing atmosphere, the obtained powder is naturally dissolved in deionized water,...

Embodiment 2

[0028] Example 2: Ba 0.88 MgAl 10 o 17 :Eu 0.12

[0029] 1) Take Ba(NO 3 ) 2 Solution (0.4mol / L) 88ml, Al(NO 3 ) 3 Solution (1mol / L) 400ml, Mg(NO 3 ) 2 Solution (0.4mol / L) 100ml, Eu(NO 3 ) 3 Solution (0.2mol / L) 24ml was mixed evenly to obtain a mixed solution;

[0030] 2) Using a urea solution to adjust the pH of the mixed solution to 1 to obtain a precursor solution;

[0031] 3) Introduce the precursor mixed solution into the ultrasonic nebulizer, send it into the reaction furnace through the carrier gas, control the temperature of the reaction furnace at 900°C, and react for 4 minutes to obtain the precursor;

[0032] 4) Place the precursor in a microwave reaction furnace, the temperature of the microwave reaction furnace is 1200°C, and the reducing atmosphere (N 2 :H 2 =1:1) for 15 minutes;

[0033] 5) Reduce to room temperature in a reducing atmosphere, the obtained powder is naturally dissolved in deionized water, washed with nitric acid solution, finally w...

Embodiment 3

[0034] Example 3: Ba 0.9 Mg 1.1 Al 10 o 17 :Eu 0.1

[0035] 1) Take Ba(NO 3 ) 2 Solution (0.4mol / L) 90ml, Al(NO 3 ) 3 Solution (1mol / L) 400ml, Mg(NO 3 ) 2 Solution (0.4mol / L) 110ml, Eu(NO 3 ) 3 20ml of the solution (0.2mol / L) was mixed evenly to obtain a mixed solution;

[0036] 2) Using ammonia water to adjust the pH of the mixed solution to 3 to obtain a precursor solution;

[0037] 3) Introduce the precursor mixed solution into the ultrasonic nebulizer, send it into the reaction furnace through the carrier gas, control the temperature of the reaction furnace to 1100°C, and react for 2 minutes to obtain the precursor;

[0038] 4) Put the precursor in a microwave reaction furnace, the temperature of the microwave reaction furnace is 1100°C, and place it in a reducing atmosphere in the microwave reaction furnace (N 2 :H 2 =1:3) for 20 minutes;

[0039] 5) Reduce to room temperature in a reducing atmosphere, the obtained powder is naturally dissolved in deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com