Preparation method and application of nanoscale beta-carotene particles

A carotene and nano-scale technology, which is applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of affecting product perception, poor product stability, and can only reach the micron level. Excellent solubilization performance, improved stability, and reduced interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

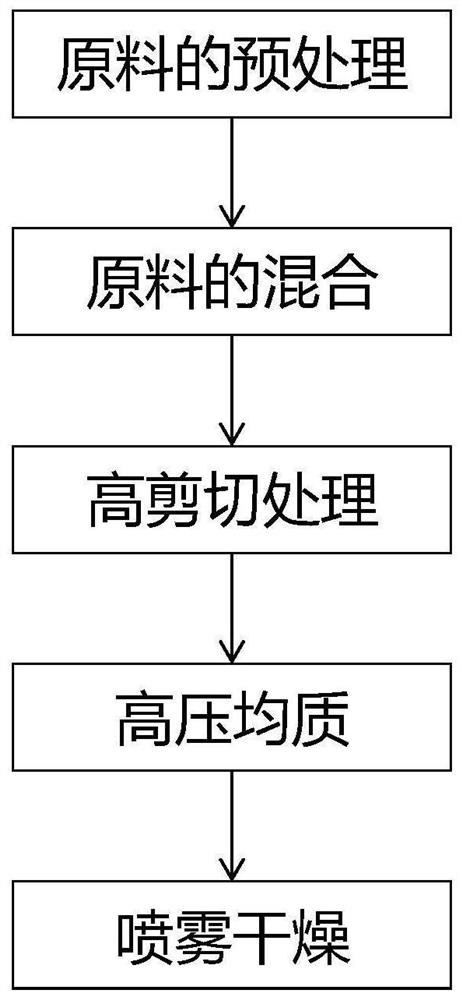

[0031] A preparation method for nanoscale β-carotene particles, characterized in that it comprises the steps of:

[0032] S1. Raw material pretreatment: in parts by weight, mix 1 part of β-carotene crystals with 8 parts of soybean oil, heat to 120° C. to dissolve, and obtain β-carotene oil suspension;

[0033] S2. Mixing of raw materials: in parts by weight, add 0.2 parts of vitamin E to the β-carotene oil suspension obtained in step S1, and mix well to obtain the oil phase material; mix 1 part of palmitin P90, 0.2 parts of high Hydrolyzed sunflower lecithin, 0.5 parts of enzyme-modified isoquercetin (EMIQ), 80 parts of maltodextrin and 200 parts of water are evenly mixed to obtain the water phase material;

[0034] S3. High-shear treatment: the water-phase material obtained in step S2 is sheared by a shearing machine, the shearing speed is 15,000 rpm, and when the temperature of the water-phase material reaches 50°C, slowly add the oil-phase material , continue to shear unti...

Embodiment 2

[0038] A preparation method for nanoscale β-carotene particles, characterized in that it comprises the steps of:

[0039] S1. Raw material pretreatment: in parts by weight, 1.5 parts of β-carotene crystals are mixed with 10 parts of a mixture of rapeseed oil, coconut oil and palm oil, heated to 128° C. to dissolve, and β-carotene oil suspension is obtained;

[0040] S2. Mixing of raw materials: In parts by weight, add 0.3 parts of a mixture of tert-butylhydroquinone and dibutylhydroxytoluene to the β-carotene oil suspension obtained in step S1, and mix well to obtain an oil phase material ; After mixing 3 parts of glyceryl palmitate P90, 0.6 part of high hydrolyzed sunflower lecithin, 0.7 part of vitamin C and phytic acid mixture, 85 parts of maltodextrin and 240 parts of water, the water phase material is obtained;

[0041] S3. High-shear treatment: the water-phase material obtained in step S2 is sheared by a shearing machine, and the shearing speed is 18000 rpm. When the tem...

Embodiment 3

[0045] A preparation method for nanoscale β-carotene particles, characterized in that it comprises the steps of:

[0046] S1. Raw material pretreatment: in parts by weight, mix 2 parts of β-carotene crystals with 12 parts of a mixture of coconut oil and palm oil, heat to 135° C. to dissolve, and obtain β-carotene oil suspension;

[0047] S2. Mixing of raw materials: in parts by weight, add 0.4 parts of a mixture of butylhydroxyanisole, gallic acid and tea polyphenols to the β-carotene oil suspension obtained in step S1, and mix well to obtain an oil phase material; Mix 5 parts of glyceryl palmitate P90, 1 part of highly hydrolyzed sunflower lecithin, 1 part of a mixture of enzyme-modified isoquercetin (EMIQ) and phytic acid, 90 parts of maltodextrin and 270 parts of water to obtain water Phase material;

[0048] S3. High-shear treatment: the water-phase material obtained in step S2 is sheared by a shearing machine, the shearing speed is 20,000 rpm, and when the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com