High-efficiency energy-saving triple-effect forced circulation evaporation system

A technology of forced circulation evaporation and three-effect evaporation, which is applied in the field of evaporation system, can solve the problems of long material and steam flow, bloated and complicated equipment layout, and large steam consumption, so as to save steam consumption, reduce equipment investment cost, Effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

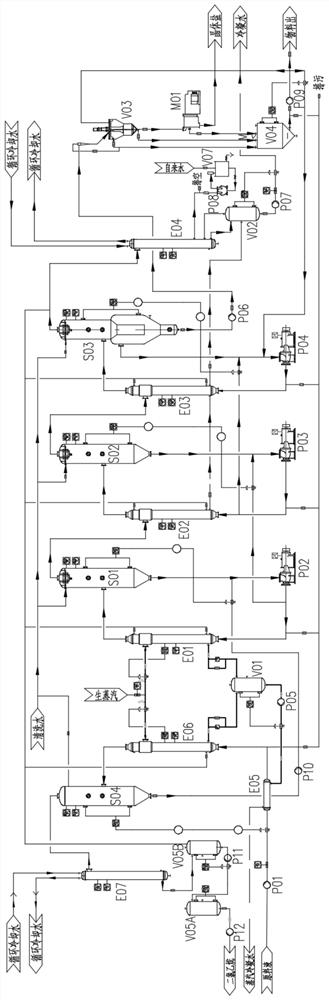

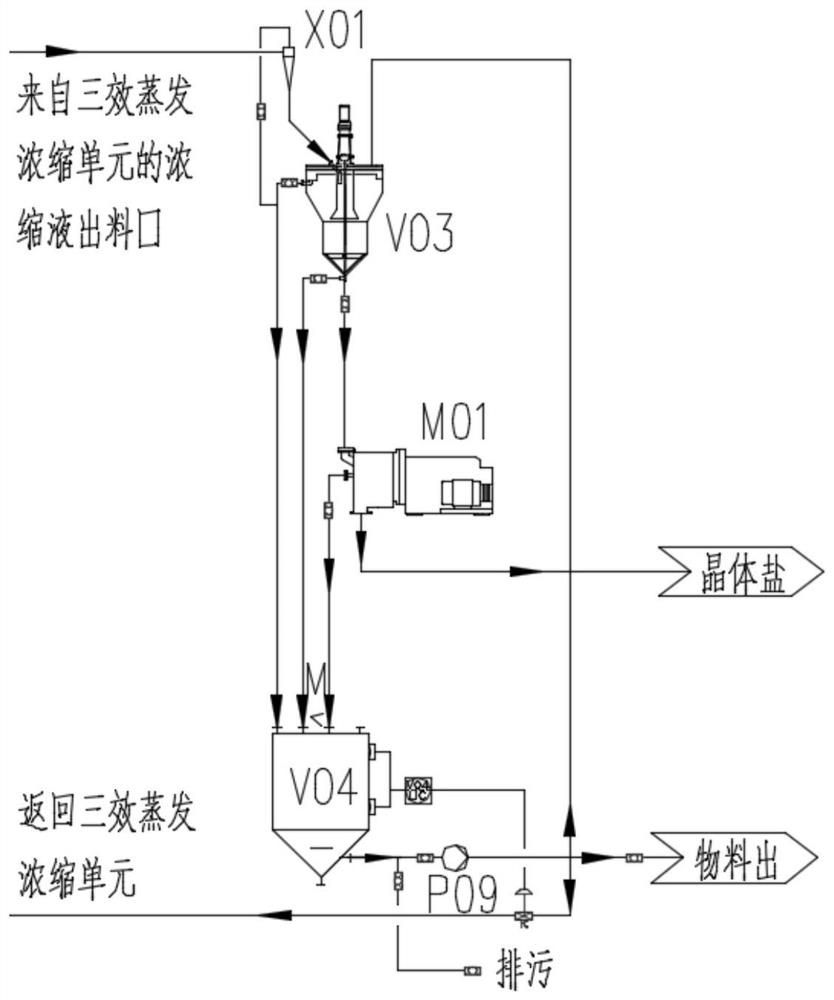

[0040] Combine figure 1 As shown, a high-efficiency energy-saving three-efficiency circulation evaporation system, including a flash device, a three-effect evaporation concentrator, a crystalline device, and a vacuum negative pressure device, wherein:

[0041] The flashing device includes a flash tank S04, a flash heater E06, a flash condenser E07, and an organic substance receiving tank, and the raw material liquid is opened into the steam cold gear preheater in the steam cold gear preheater in the steam cold gear preheater. E06, the raw material can take the pipe of the steam colder preheater E05, the discharge port of the flash heater E06 is connected to the material feed port of the flash tank S04, and the liquid phase of the flash tank S04 passes. The flash cycle pump P10 is connected to the feed port of the flash heater E06, which constitutes the circulating flashing unit, the gas phase discharge port of the flash tank S04 and the feed port of the flash condenser E07, flash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com