Ti/Al composite wire for additive manufacturing of TiAl alloy and preparation method of Ti/Al composite wire

A technology of additive manufacturing and composite wire, which is applied in manufacturing tools, additive processing, metal processing equipment, etc., can solve the problems of poor plasticity at room temperature of TiAl alloy, and it is difficult to use additive manufacturing. Quality, dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

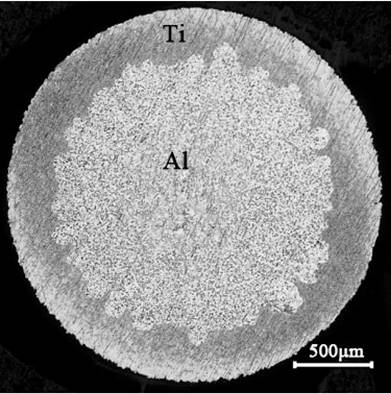

[0031] In this embodiment, the Ti / Al composite wire for the additive manufacturing of TiAl alloy is made of an inner core material of 1080 aluminum rod and an outer material TA1 titanium tube coated on the inner core material; the cross-section of the TA1 titanium tube and the 1080 aluminum rod The area ratio is 0.93:1.

[0032] The preparation method of Ti / Al composite wire for additively manufacturing TiAl alloy in this embodiment comprises the following steps:

[0033] Step 1. According to the production of the target product Ti / Al composite wire, select a TA1 titanium tube of Φ15mm×2.1mm (outer diameter×wall thickness) and a 1080 aluminum rod of Φ10.8mm×1m (diameter×length) for pickling in sequence and ultrasonic cleaning to obtain clean TA1 titanium tubes and 1080 aluminum rods;

[0034] Step 2, importing the clean 1080 aluminum rod obtained in step 1 into clean TA1 titanium to obtain a composite wire blank;

[0035] Step 3: Perform swaging and intermediate annealing trea...

Embodiment 2

[0044] The difference between this example and Example 1 is that the system of swaging and intermediate annealing in step 3 is: when the amount of swaging deformation is 30%, stress relief annealing is performed, and the temperature of stress relief annealing is 610°C , the time is 70 minutes; the drawing and intermediate annealing treatment system in step 4 is: when the drawing deformation is 10%, the stress relief annealing is carried out, the temperature of the stress relief annealing is 550 ° C, and the time is 60 minutes.

[0045] The Ti / Al composite wire prepared in this example was used to prepare TiAl alloy by arc additive manufacturing. The obtained TiAl alloy had good molding quality, smooth surface, and no defects such as cracks, pores, welding spots, and oxidation.

Embodiment 3

[0047] The difference between this example and Example 1 is that the system of swaging and intermediate annealing in step 3 is: when the amount of swaging deformation is 25%, stress relief annealing is performed, and the temperature of stress relief annealing is 600°C , the time is 90 minutes; the drawing and intermediate annealing treatment system in step 4 is: when the drawing deformation is 15%, the stress relief annealing is carried out, the temperature of the stress relief annealing is 580 ° C, and the time is 80 minutes.

[0048] The Ti / Al composite wire prepared in this example was used to prepare TiAl alloy by arc additive manufacturing. The obtained TiAl alloy had good molding quality, smooth surface, and no defects such as cracks, pores, welding spots, and oxidation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com