System and method for preparing high-purity methyl lactate by direct esterification method

A technology of methyl lactate and lactic acid, which is applied in the field of direct esterification to prepare high-purity methyl lactate, can solve the problems of low product purity and complex methyl lactate process, achieve low polymerization degree, improve the single-pass conversion rate of lactic acid, and not easily The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

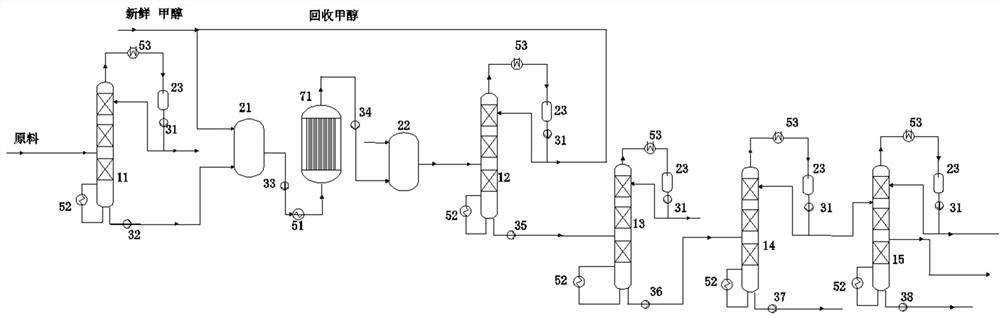

[0038] See figure 1 , the raw material lactic acid content from the tank farm is 72.03%, and the water content is 17.07%, and it is injected into the lactic acid pretreatment tower 11 for vacuum distillation. The total plate number of the lactic acid pretreatment tower 11 is 20, and the tower pressure is set at 5kPa , the reflux ratio was 0.5, and the temperature of the tower kettle was set at 110°C. The steam rising from the top of the tower is condensed by the condenser 51 and enters the reflux tank 23. Part of the material flows back into the tower, and the other part of water is extracted. The acid content of the treated lactic acid rises to 85.12%, and the water content drops to 2.00%.

[0039] The material extracted from the tower kettle is pumped into the reactant mixing tank 21 through the first pump 32 and mixed with methanol. The molar ratio of methanol to dehydrated lactic acid is 4:1. The esterification reaction takes place in the bed reactor 71, and the residence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com