Low-temperature high-activity toluene catalytic oxidation catalyst, and preparation method and application thereof

A catalytic oxidation, high activity technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of limited resources and low activity, and achieve environmental pollution. Small, excellent activity, simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

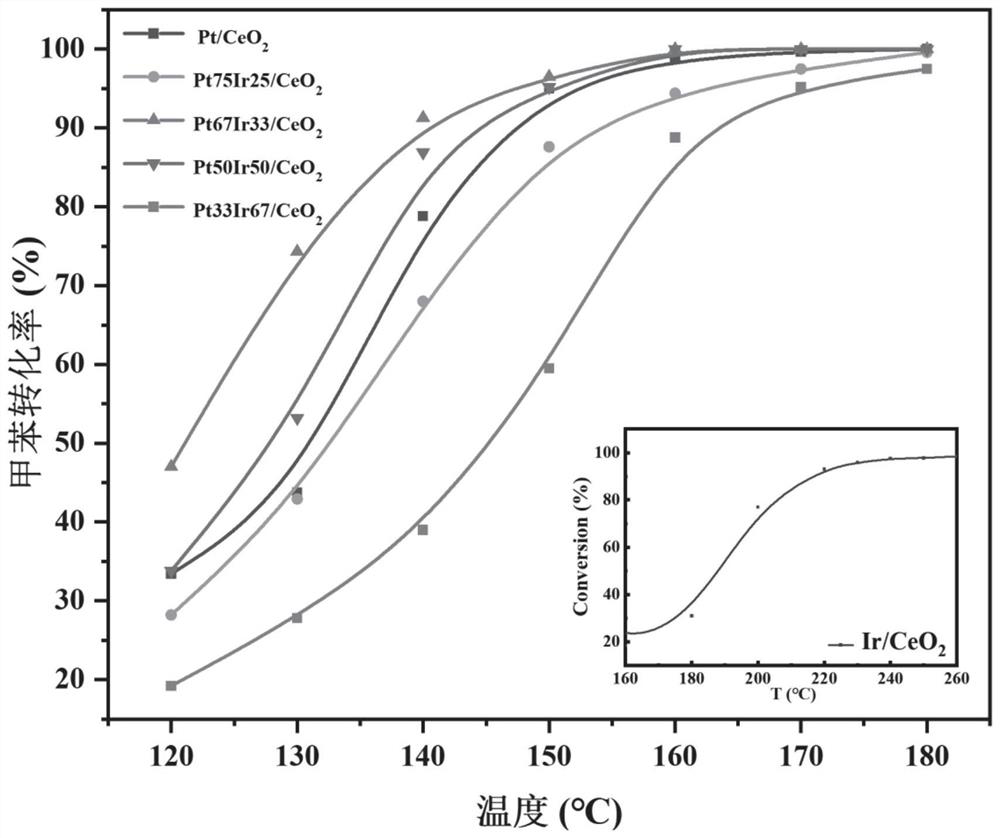

[0029] Take 2.25mL 0.02mol / L H 2 PtCl 6 ·6H 2 O solution in ethylene glycol and 0.75mL 0.02mol / L IrCl 3 The ethylene glycol solution mixed with 2.4mL 0.25mol / L NaOH ethylene glycol solution was added dropwise to 15mL ethylene glycol solution in which 100mgPVP was dissolved, and the microwave irradiation method was used to react at 150°C for 30min, and the reaction The final solution was centrifuged once with acetone, and then centrifuged twice with ethanol and n-hexane, and the obtained alloy was dispersed in the ethanol solution, added to the cerium dioxide dispersed in the ethanol solution, the loading capacity was 0.6%, and stirred at room temperature 4h, evaporated to dryness in a water bath, dried in an oven at 110°C for 4h, ground evenly, then roasted in a muffle furnace at 200°C for 2h, and reduced in a hydrogen atmosphere at 200°C for 2h to obtain a platinum-iridium alloy catalyst Pt75Ir25 supported on ceria / CeO 2 .

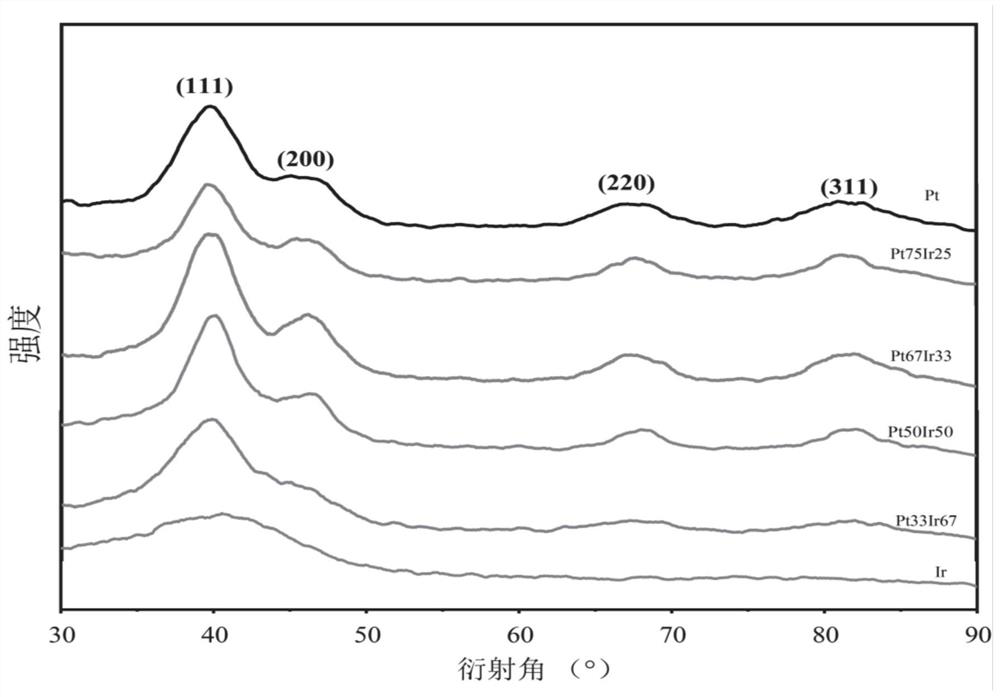

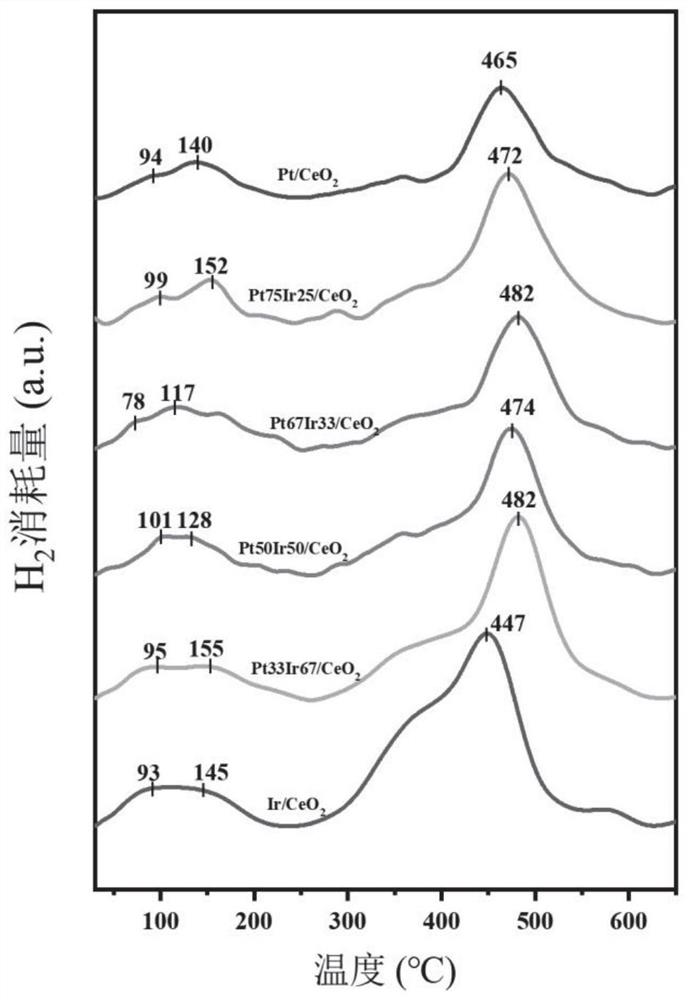

[0030] The XRD of the sample is attached fig...

Embodiment 2

[0032] Take 2mL 0.02mol / L H 2 PtCl 6 ·6H 2 O solution in ethylene glycol and 1mL 0.02mol / L IrCl 3 The ethylene glycol solution mixed with 2.4mL 0.25mol / L NaOH ethylene glycol solution was added dropwise to 15mL ethylene glycol solution in which 100mg PVP was dissolved, and the microwave irradiation method was used to react at 150°C for 30min. The solution after the reaction was centrifuged once with acetone, and then centrifuged twice with ethanol and n-hexane, and the obtained alloy was dispersed in the ethanol solution, and added to the cerium dioxide dispersed in the ethanol solution, with a loading capacity of 0.6%, at room temperature Stir for 4 hours, evaporate to dryness in a water bath, dry in an oven at 110°C for 4 hours, grind evenly, then bake in a muffle furnace at 200°C for 2 hours, and then reduce in a hydrogen atmosphere at 200°C for 2 hours to obtain a platinum-iridium alloy catalyst supported on ceria Pt67Ir33 / CeO 2 .

[0033] The XRD of the sample is att...

Embodiment 3

[0035] Take 1.5mL 0.02mol / L H 2 PtCl 6 ·6H 2 O solution in ethylene glycol and 1.5mL 0.02mol / L IrCl 3 The ethylene glycol solution mixed with 2.4mL 0.25mol / L NaOH ethylene glycol solution was added dropwise to 15mL ethylene glycol solution in which 100mgPVP was dissolved, and the microwave irradiation method was used to react at 150°C for 30min, and the reaction The final solution was centrifuged once with acetone, and then centrifuged twice with ethanol and n-hexane, and the obtained alloy was dispersed in the ethanol solution, added to the cerium dioxide dispersed in the ethanol solution, the loading capacity was 0.6%, and stirred at room temperature 4h, evaporated to dryness in a water bath, dried in an oven at 110°C for 4h, ground evenly, then roasted in a muffle furnace at 200°C for 2h, and reduced in a hydrogen atmosphere at 200°C for 2h to obtain a platinum-iridium alloy catalyst Pt50Ir50 supported on ceria / CeO 2 .

[0036] The XRD of the sample is attached figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com