A kind of nano crystal nucleus early strengthening agent and preparation method thereof

A technology of early strength agent and nano crystal, which is applied in the field of nano crystal nucleus early strength agent and its preparation, can solve the problems of limited particle size control effect, large structural molecular weight, and inability to arrange dispersants tightly, so as to facilitate uniform nucleation , High activity, low foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

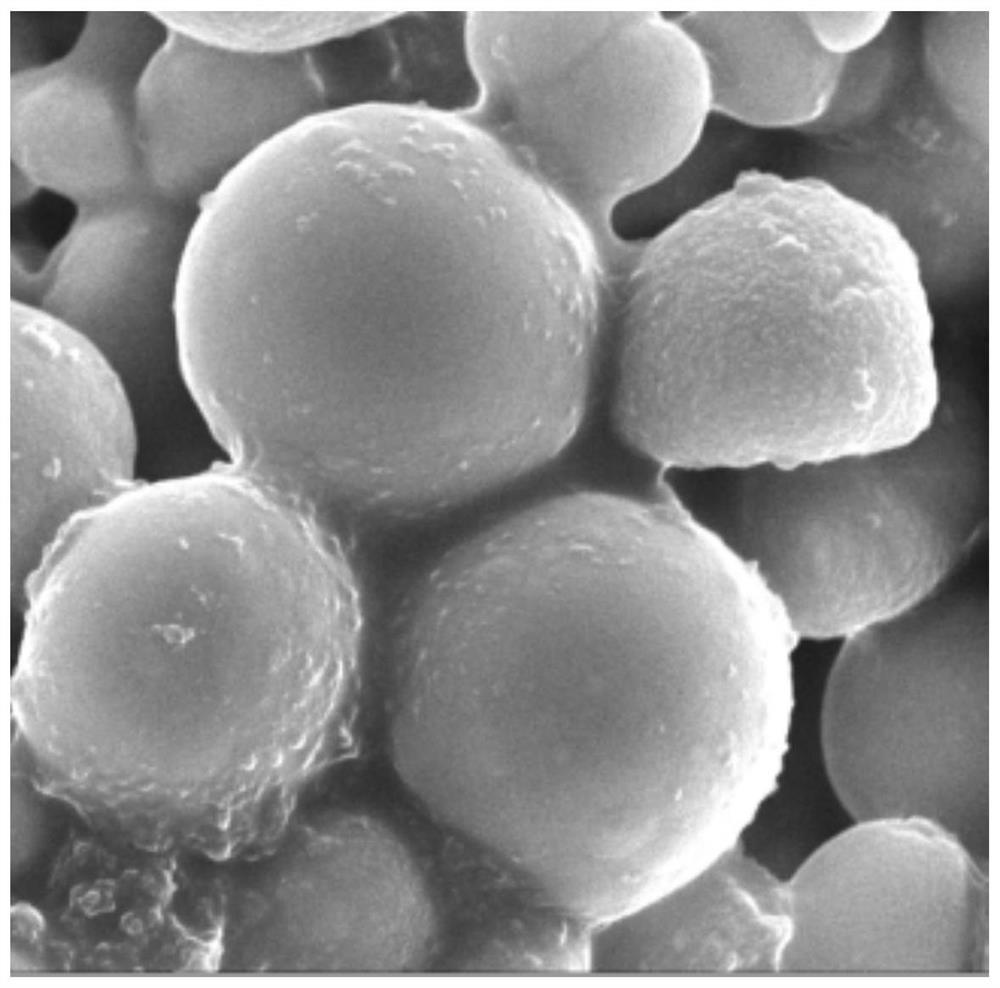

Image

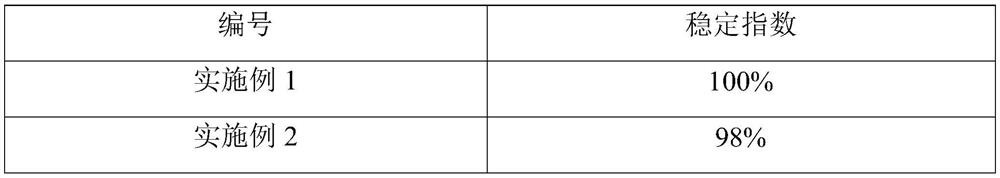

Examples

Embodiment 1

[0042] A nanocrystalline nucleus early strength agent, comprising the following components by weight:

[0043] 0.4% of dispersant, 5% of calcium salt, 5% of composite silicon salt, and the balance is water; wherein, the dispersant includes a 2:1 mass ratio of phosphoric acid-terminated hydroxyl group-modified EO / PO block polycondensate and acrylic acid-polyoxygen vinyl ether copolymer;

[0044] Wherein, the preparation method of phosphoric acid terminal hydroxyl modified EO / PO block polycondensate is as described above, and its chemical structural formula is:

[0045] [CH 3 CH 2 (CH 2 CH 2 O) 8 (CHCH 3 CH 2 O) 5 ]2-OP(OH);

[0046] The calcium salt includes calcium nitrate and calcium acetate in a weight ratio of 1:1;

[0047] The composite silicon salt includes sodium silicate and lithium silicate in a mass ratio of 10:1, and the doping amount of polyethylene glycol in the composite silicon salt is 0.3% of the total mass of sodium silicate and lithium silicate.

[...

Embodiment 2

[0053] A nanocrystalline nucleus early strength agent, comprising the following components by weight:

[0054] 1.2% of dispersant, 10% of composite calcium salt, 10% of composite silicon salt, and the balance is water; wherein, the dispersant includes phosphate-terminated hydroxyl group modified EO / PO block polycondensate and acrylic acid-polyester with a mass ratio of 8:1 Oxyethylene ether copolymer;

[0055] Wherein, the preparation method of phosphoric acid terminal hydroxyl modified EO / PO block polycondensate is as described above, and its chemical structural formula is:

[0056] [CH 3 CH 2 (CH 2 CH 2 O) 8 (CHCH 3 CH 2 O) 5 ]2-OP(OH);

[0057] The calcium salt includes calcium nitrate and calcium chloride in a weight ratio of 2:3;

[0058] The composite silicon salt includes sodium silicate and lithium silicate in a mass ratio of 5:5, and the doping amount of polyethylene glycol in the composite silicon salt is 0.2% of the total mass of the sodium silicate and li...

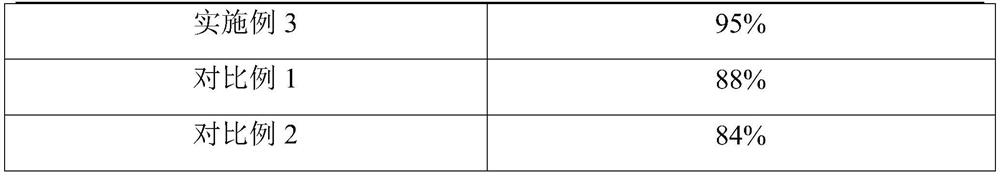

Embodiment 3

[0064] A nanocrystalline nucleus early strength agent, comprising the following components by weight:

[0065] 3% of dispersant, 15% of calcium salt, 15% of composite silicon salt, and the balance of water; wherein, the dispersant includes a 10:1 mass ratio of phosphoric acid-terminated hydroxyl group-modified EO / PO block polycondensate and acrylic acid-polyoxygen vinyl ether copolymer;

[0066] Wherein, the preparation method of phosphoric acid terminal hydroxyl modified EO / PO block polycondensate is as described above, and its chemical structural formula is:

[0067] [CH 3 CH 2 (CH 2 CH 2 O) 8 (CHCH 3 CH 2 O) 5 ]2-OP(OH);

[0068] Calcium salts include calcium nitrate, calcium chloride and calcium acetate in a mass ratio of 8:1:1;

[0069] The composite silicon salt includes sodium silicate and lithium silicate in a mass ratio of 8:1, and the doping amount of polyethylene glycol in the composite silicon salt is 0.1% of the total mass of the sodium silicate and lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com