Wet chemical method for preparing lead-based relaxor ceramics with perovskite structure or their solid solutions

A technology of perovskite structure and wet chemical method, which is applied in the field of ceramic preparation, can solve the problems of difficult removal of impurities, toxic substances, and high price, and achieve the effects of short mixing time, low cost, and easy production control and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

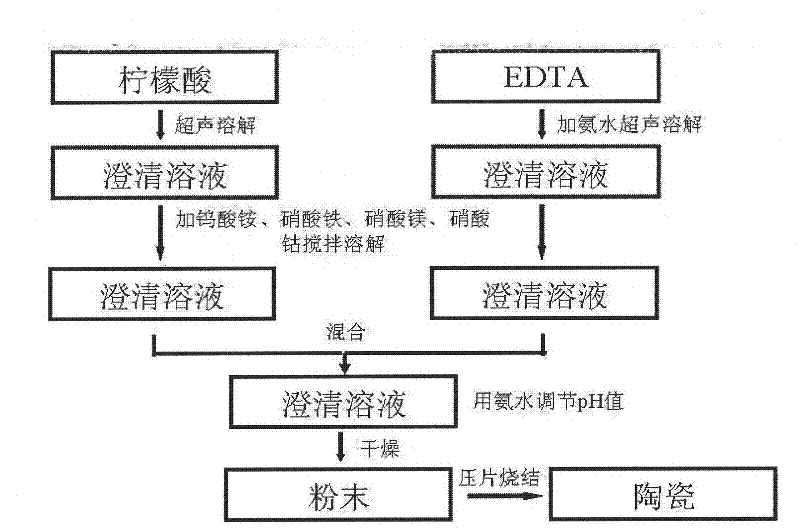

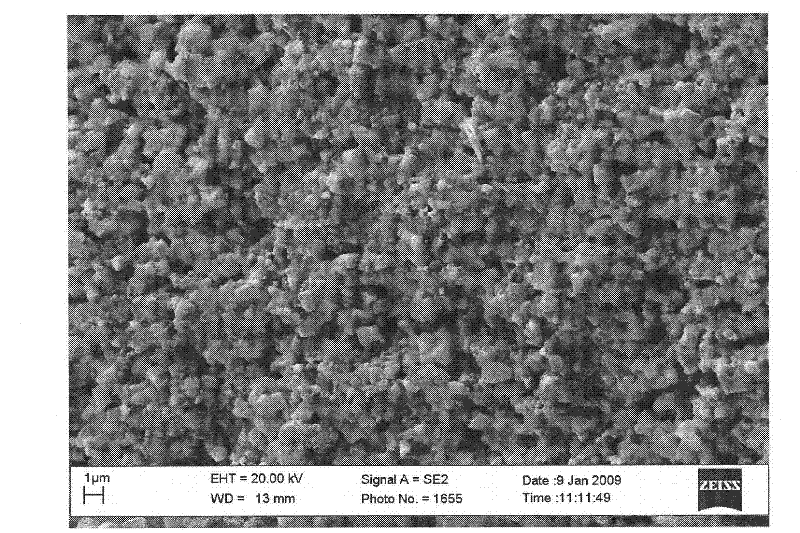

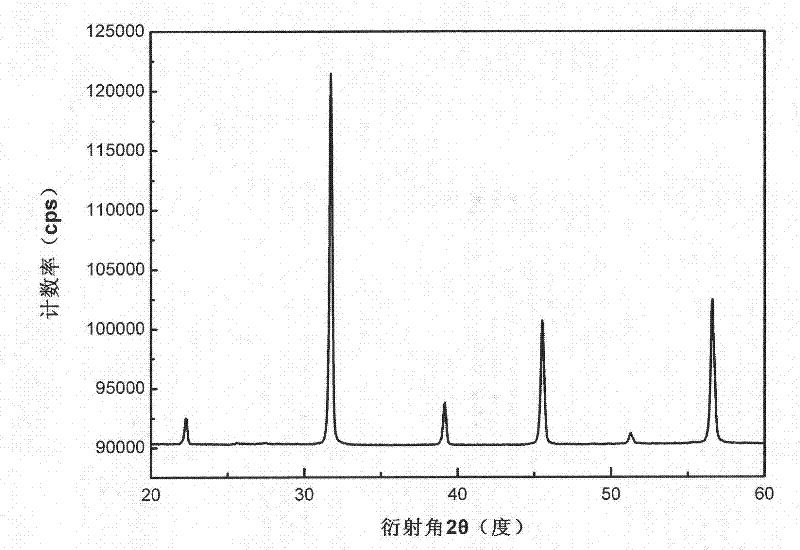

[0060] Weigh lead acetate, ferric nitrate and ammonium tungstate according to the molar ratio of Pb:Fe:W 3:2:1, and weigh citric acid and ethylene glycol respectively according to the molar ratio of complexing agent and metal ion of 2:1. Aminetetraacetic acid, citric acid and ethylenediaminetetraacetic acid were dissolved in deionized water respectively, the concentration of citric acid was 1.0Mol / L, the concentration of ethylenediaminetetraacetic acid was 1.0Mol / L, and then according to figure 1 The process flow diagram shown is synthesized and prepared as figure 2 Pure Pb(Fe 2 / 3 W 1 / 3 )O 3 , the crystal grains of the product present a cubic shape, with an average size of about 250nm, and the X-ray diffraction spectrum is shown in image 3 . Among them, the optimum sintering temperature is 725°C, and the purity is as high as 99wt%.

Embodiment 2

[0062] According to the molar ratio of Pb:Fe:W:Bi 3:4:1:2, weigh appropriate weights of lead acetate, iron nitrate, ammonium tungstate and bismuth nitrate, respectively according to the molar ratio of complexing agent and metal ion of 2:1 Weigh citric acid and ethylenediaminetetraacetic acid, citric acid and ethylenediaminetetraacetic acid are dissolved in deionized water respectively, the concentration of citric acid is 1.5Mol / L, and the concentration of ethylenediaminetetraacetic acid is 1.5Mol / L, then according to figure 1 The process flow diagram shown synthesizes and prepares 0.6Pb(Fe 2 / 3 W 1 / 3 )O 3 -0.4BiFeO 3 Single-phase solid solution, the average size of cubic crystal grains is about 100nm, and its morphology is as follows Figure 4 Shown, the X-ray diffraction spectrum is shown in Figure 5 . Among them, the optimum sintering temperature is 700°C, and the purity of the obtained bismuth-doped iron lead tungstate is as high as 99wt%.

Embodiment 3

[0064] Weigh appropriate weights of lead acetate, iron nitrate, ammonium tungstate and magnesium nitrate according to the molar ratio of Pb:Fe:W:Mg 5:2:2:1, and weigh according to the molar ratio of complexing agent to metal ion of 2:1 Get citric acid and ethylenediaminetetraacetic acid, citric acid and ethylenediaminetetraacetic acid are dissolved in deionized water respectively, the concentration of citric acid is 2.0Mol / L, the concentration of ethylenediaminetetraacetic acid is 2.0Mol / L, and then according to figure 1 0.6Pb(Fe 2 / 3 W 1 / 3 )O 3 -0.4Pb(Mg 1 / 2 W 1 / 2 )O 3 Single-phase solid solution, its X-ray diffraction spectrum is as follows Figure 6 shown. Among them, the optimum sintering temperature is 700°C, and the purity of the obtained magnesium-doped iron lead tungstate is as high as 99wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com