Geopolymer-stabilized phosphate tailing pavement base layer and preparation method thereof

A technology of pavement base and phosphorus tailings, applied in the direction of roads, roads, solid waste management, etc., can solve problems such as resource consumption, non-conformity with green and low-carbon development concepts, and carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The application also provides a preparation method for geopolymer-stabilized phosphorus tailings pavement base, comprising the following steps:

[0039] Mix one or two of phosphorus slag powder and fly ash, calcium carbide slag and phosphorus tailings according to the ratio of raw materials, and then add water to obtain a mixture;

[0040] The mixture is paved, rolled and formed and maintained in sequence to obtain a geopolymer-stabilized phosphorus tailings pavement base.

[0041] More specifically, the preparation method of the geopolymer-stabilized phosphorus tailings pavement base is as follows:

[0042] 1) Mixing of raw materials: mix the calcium carbide slag, phosphorus slag powder, fly ash and phosphorus tailings measured by the ratio composition evenly by factory mixing method, add water, and adjust the water content during the mixing process to make the mixture The water content is 0.5-1% of the optimal water content, and the water content is tested every 2 ho...

Embodiment 1

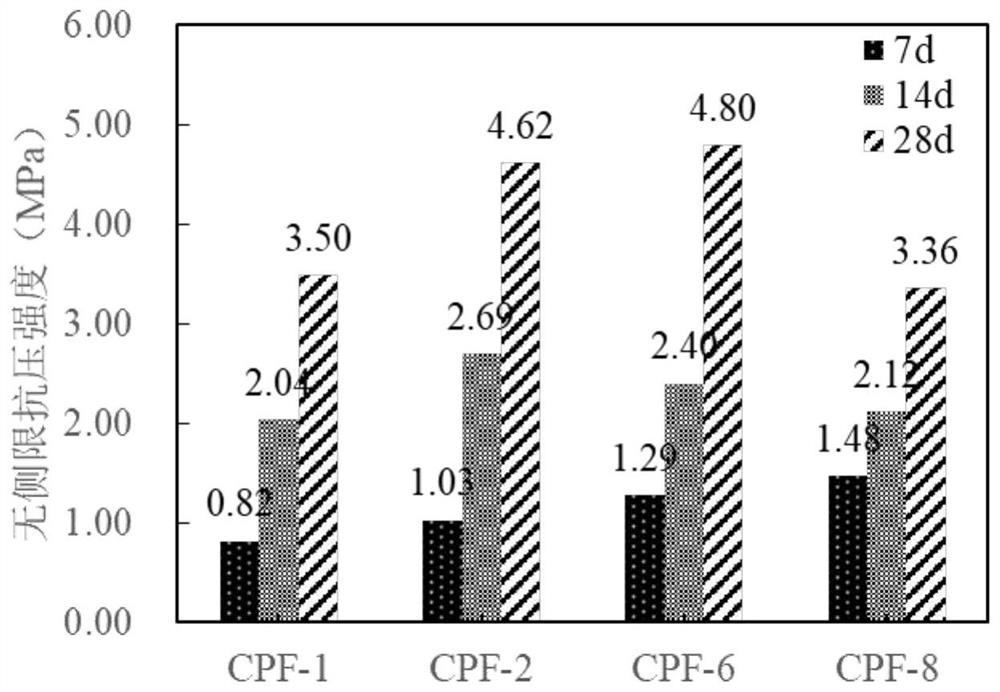

[0057] Calcium carbide slag-phosphorus slag powder base polymer stabilized phosphorus tailings pavement base: Carbide carbide slag, phosphorus slag powder, and phosphorus tailings are weighed according to the design components in Table 2, according to the "Highway Engineering Inorganic Binder Stable Material Test Regulations" (JTG E51-2009) carry out the compaction test to determine the optimum moisture content and maximum dry density of the mixture, form the test piece according to the controlled compaction degree and measure its unconfined compressive strength. Phosphorus tailings are taken from the tailings warehouse of Guizhou Chuanheng Chemical Co., Ltd., and the specific surface area of carbide slag is ≥300m 2 / kg, phosphorus slag powder specific surface area ≥ 400m 2 / kg, changing the mass ratio of calcium carbide slag and phosphorus slag powder, and carrying out the unconfined compressive strength test according to the compaction degree of 95%. .

[0058] From the ...

Embodiment 2

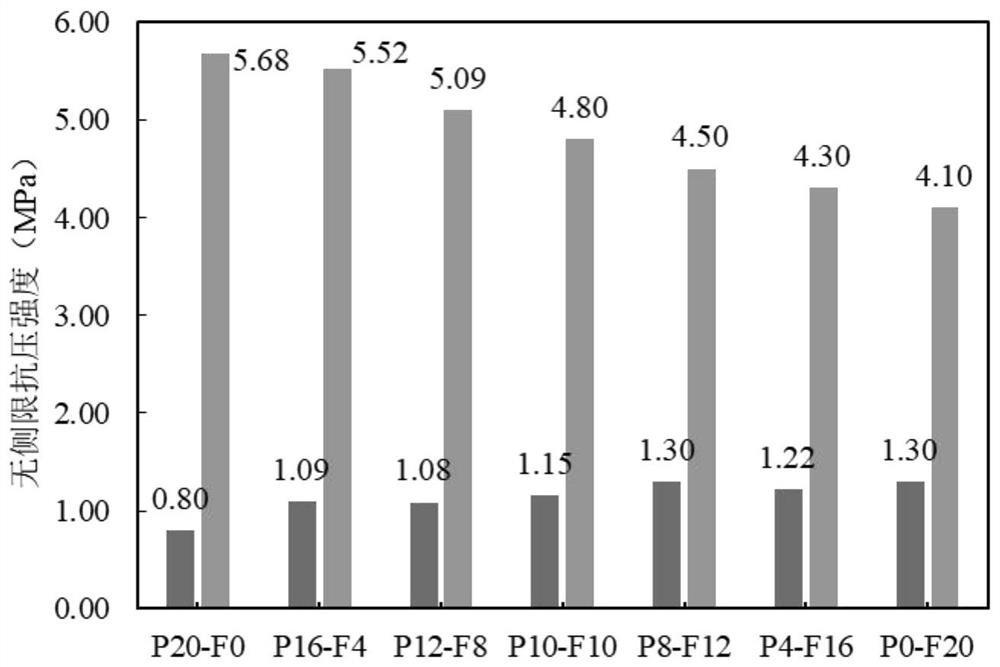

[0060] Calcium carbide slag-phosphorus slag powder-fly ash geopolymer stabilized phosphorus tailings pavement base: Carbide carbide slag, phosphorus slag powder, and phosphorus tailings were weighed according to the design components in Table 3, according to "Highway Engineering Inorganic Binder Stabilization According to the "Material Test Regulations" (JTG E51-2009), the compaction test is carried out to determine the optimum moisture content and maximum dry density of the mixture, and the test pieces are formed according to the controlled compaction degree and their unconfined compressive strength is measured. Phosphorus tailings are taken from the tailings warehouse of Guizhou Chuanheng Chemical Co., Ltd., and the specific surface area of carbide slag is ≥300m 2 / kg, phosphorus slag powder specific surface area ≥ 400m 2 / kg, fly ash specific surface area ≥ 750m 2 / kg, adjust the amount of phosphorus slag powder and fly ash, and carry out the unconfined compressive stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com