Rice soil conditioner for reducing cadmium and increasing yield and preparation method thereof

A soil conditioner and rice technology, applied in soil conditioning materials, chemical instruments and methods, microbial treatment, etc., can solve the problems of polluting the environment, destroying the living environment of rural and urban residents, and uneven distribution of rice soil conditioner materials. The effect of improving uniformity and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A rice soil conditioner for reducing cadmium production, the formula is as follows: 15 parts of sheep manure, 10 parts of sawdust, 20 parts of biomass charcoal, 10 parts of oil shale slag, 5 parts of wood vinegar, 15 parts of shell powder, sea foam 15 parts of stone, 9.8 parts of white clay, and 0.2 parts of microbial agent.

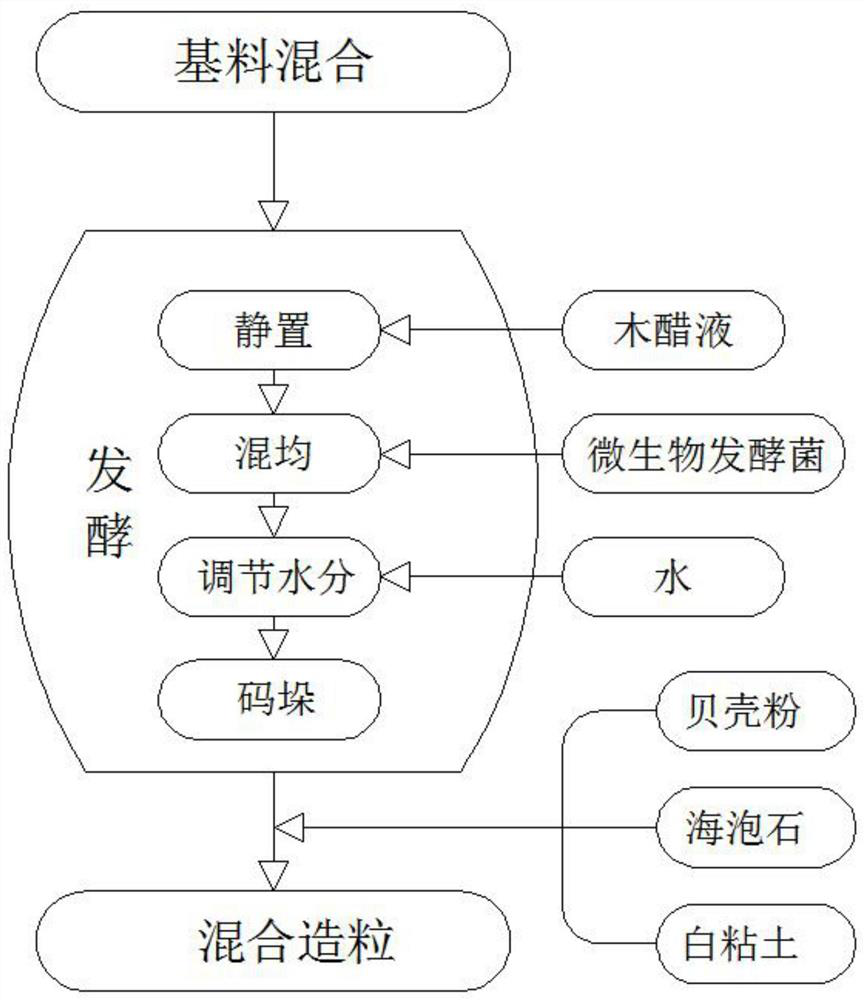

[0031] A preparation method of a paddy soil conditioner for reducing cadmium and increasing yield, the specific steps are as follows:

[0032] Step 1: base material mixing; take appropriate amount of various raw materials according to the ratio of raw materials, dilute wood vinegar 5 times for later use, use a mixing device to mix sheep manure, sawdust, biochar and oil shale slag evenly, In this process, firstly, remove the top cover 2 and the fixed plate 14 of the mixing device, put sheep manure, sawdust, biomass charcoal and oil shale slag into the mixing shell 1, and then put the top cover 2 and the fixed plate 14 Reset, so that the communicat...

Embodiment approach

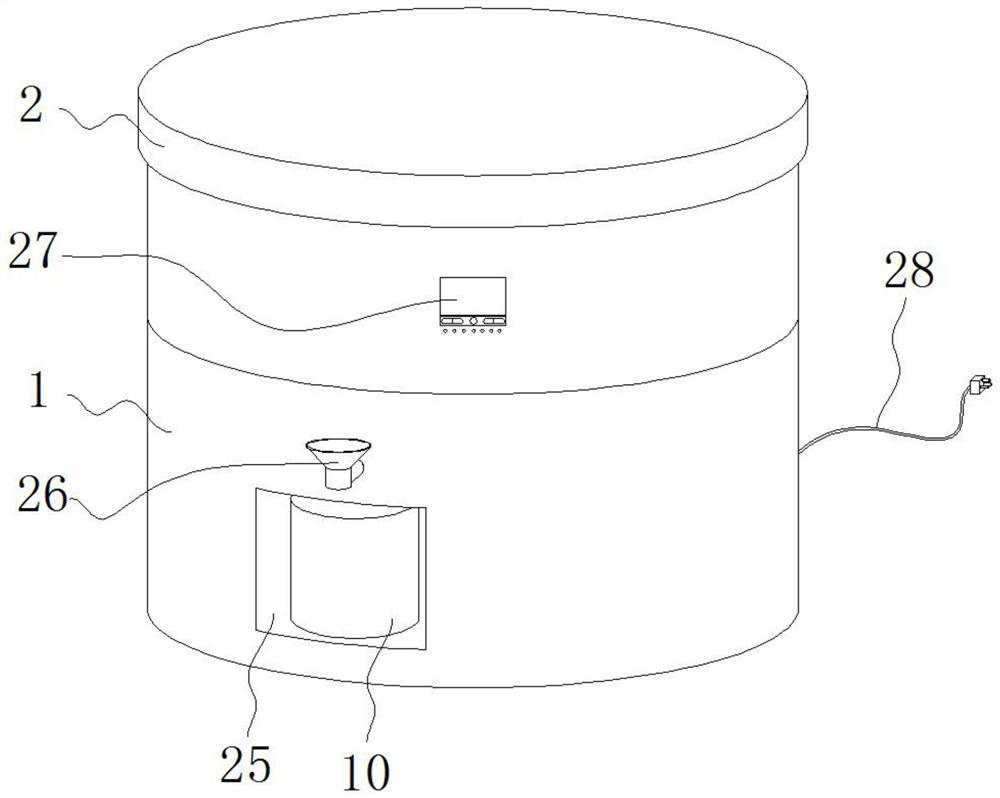

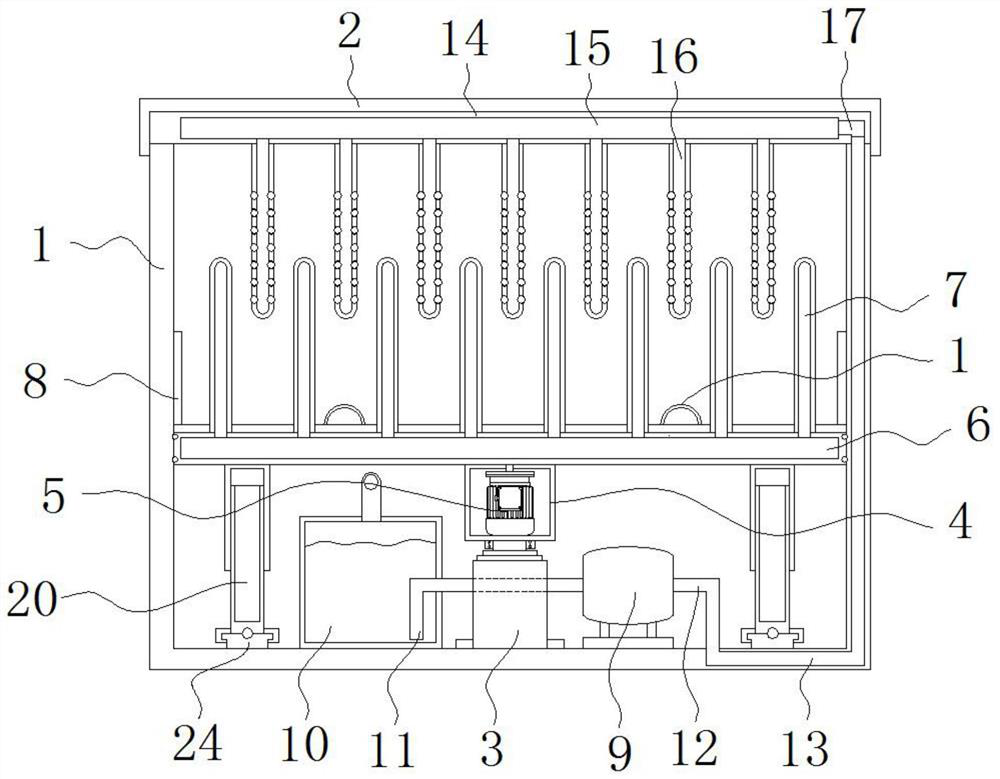

[0035] As a preferred embodiment of the present invention, the mixing device includes a mixing housing 1 and a top cover 2, and a multi-stage electric push rod 3 is fixedly installed on the inner wall of the bottom of the mixing housing 1, and the multi-stage electric push rod 3 is fixedly installed on the output shaft of the motor shell 4, and the motor 5 is fixedly installed in the said motor shell 4, and the movable disc 6 is fixedly installed on the output shaft of the said motor 5, and the outer side of the said movable disc 6 is attached Closed on the inner side of the mixing shell 1, the top of the movable disc 6 is fixedly equipped with several movable stirring rods 7, and a movable frame 8 is installed in the described mixing casing 1, and the movable frame 8 is connected with the movable stirring rod A through hole is opened at the position corresponding to 7, and the movable frame 8 is sleeved on the top of the movable stirring rod 7 through the through hole, and a w...

Embodiment 2

[0043] A rice soil conditioner for reducing cadmium production, the formula is as follows: 15 parts of sheep manure, 10 parts of sawdust, 20 parts of biomass charcoal, 10 parts of oil shale slag, 5 parts of wood vinegar, 15 parts of shell powder, sea foam 15 parts of stone, 9.8 parts of white clay, and 0.2 parts of microbial agent.

[0044] A preparation method of a paddy soil conditioner for reducing cadmium and increasing yield, the specific steps are as follows:

[0045] Step 1: base material mixing; take appropriate amount of various raw materials according to the ratio of raw materials, dilute wood vinegar 6 times for later use, use a mixing device to mix sheep manure, sawdust, biochar and oil shale slag evenly, In this process, firstly, remove the top cover 2 and the fixed plate 14 of the mixing device, put sheep manure, sawdust, biomass charcoal and oil shale slag into the mixing shell 1, and then put the top cover 2 and the fixed plate 14 Reset, so that the communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com