Star-shaped polyacrylate OLED photosensitive resin and synthesis method thereof

A polyacrylate and synthetic method technology, applied in the field of OLED photosensitive resin, can solve the problems of poor heat resistance and solvent resistance, low solid content, low hardness, etc., and achieve improved workability, improved refractive index, and high transmission. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

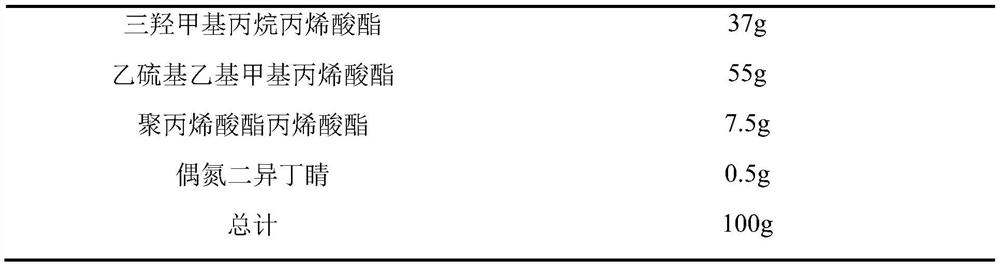

[0022] A kind of synthesis of star-shaped polyacrylate OLED photosensitive resin, the raw material type and consumption of each component are as table 1 (acetone is used as solvent):

[0023] Table 1:

[0024]

[0025] Preparation process: Take 37g of trimethylolpropane acrylate, 55g of ethylthioethyl methacrylate, 7.5g of polyacrylate acrylate, 0.5g of azobisisobutyronitrile and 25g of acetone, and add them to the In the reaction kettle, under the protection of nitrogen, the temperature was slowly raised to 50°C. After the raw materials were completely dissolved, the temperature was raised to 70°C for polymerization, and then the temperature was lowered to 40°C to synthesize a star-shaped polyacrylate OLED photosensitive resin.

[0026] Properties of star polyacrylate OLED photosensitive resin: solid content, 82%; viscosity, 3800cP.

Embodiment 2

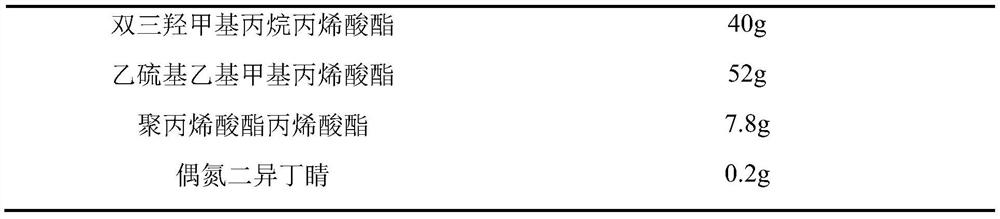

[0028] A kind of synthesis of star-shaped polyacrylate OLED photosensitive resin, the raw material type and consumption of each component are as table 2 (acetone is used as solvent):

[0029] Table 2:

[0030]

[0031]

[0032] Preparation process: Take 40g of ditrimethylolpropane acrylate, 52g of ethylthioethyl methacrylate, 7.8g of polyacrylate acrylate, 0.2g of azobisisobutyronitrile and 40g of acetone, and add them to the In the reaction kettle of the device, under the protection of nitrogen, the temperature is slowly raised to 50°C. After the raw materials are completely dissolved, the temperature is raised to 70°C for polymerization reaction, and then the temperature is lowered to 40°C to synthesize a star-shaped polyacrylate OLED photosensitive resin.

[0033] Properties of star-shaped polyacrylate OLED photosensitive resin: solid content, 73%; viscosity, 1300cP.

Embodiment 3

[0035] A kind of synthesis of star-shaped polyacrylate OLED photosensitive resin, the raw material type and consumption of each component are as table 3 (acetone is used as solvent):

[0036] table 3:

[0037]

[0038] Preparation process: Take 20g ditrimethylolpropane acrylate, 22g trimethylolpropane acrylate, 52g ethylthioethyl methacrylate, 5.5g polyacrylate acrylate, 0.5g azobisisobutyronitrile and 30g of acetone were added to the reaction kettle with a reflux device. Under the protection of nitrogen, the temperature was slowly raised to 50°C. Acrylic OLED photosensitive resin.

[0039] Properties of star polyacrylate OLED photosensitive resin: solid content, 75%; viscosity, 1700cP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com