Nano-zinc oxide/collagen-based antibacterial dressing and preparation method thereof

A nano-zinc oxide and collagen technology, applied in medical science, absorbent pads, bandages, etc., can solve the problems of restricting collagen dressings, enhancing cytotoxicity, high cytotoxicity, etc., to improve the quality of healing, reduce biological toxicity, and improve mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

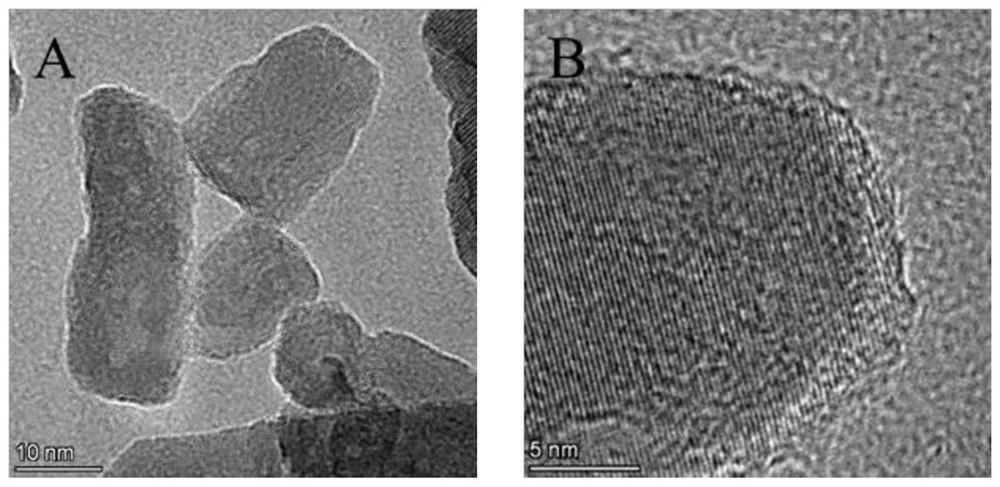

[0031] (1) Preparation of nano zinc oxide wrapped by polydopamine:

[0032] After heating 50 parts by volume of 0.2 mol / L sodium hydroxide solution to 100°C, slowly add an equivalent amount of 0.1 mol / L zinc acetate solution under stirring conditions, and react at constant temperature for 30 minutes. The suspension was separated by filtration, and vacuum-dried at 100°C to obtain nano-zinc oxide;

[0033] 0.1 parts by mass of dopamine hydrochloride was dissolved in 0.05 mol / L Tris buffer solution of pH 8.5 to obtain a solution of dopamine hydrochloride with a mass fraction of 0.1%, and 1 part by mass of nano-zinc oxide was added, and the reaction was stirred at room temperature for 1 d. The suspension was separated by filtration, and vacuum-dried at 60°C to prepare polydopamine-coated nano-zinc oxide;

[0034] (2) Preparation of modified collagen:

[0035] 1 mass part of type I collagen was dissolved in 0.5 mol / L acetic acid solution to obtain a collagen solution with a mass ...

Embodiment 2

[0038] (1) Preparation of nano zinc oxide wrapped by polydopamine:

[0039] After heating 50 parts by volume of 0.2 mol / L sodium hydroxide solution to 100°C, slowly add an equivalent amount of 0.1 mol / L zinc acetate solution under stirring conditions, and react at constant temperature for 30 minutes. The suspension was separated by filtration, and vacuum-dried at 100°C to obtain nano-zinc oxide;

[0040]0.1 parts by mass of dopamine hydrochloride was dissolved in 0.05 mol / L Tris buffer solution of pH 8.5 to obtain a solution of dopamine hydrochloride with a mass fraction of 0.1%, and 1 part by mass of nano-zinc oxide was added, and the reaction was stirred at room temperature for 1 d. The suspension was separated by filtration, and vacuum-dried at 60°C to prepare polydopamine-coated nano-zinc oxide;

[0041] (2) Preparation of modified collagen:

[0042] 1 mass part of type I collagen was dissolved in 0.5 mol / L acetic acid solution to obtain a collagen solution with a mass c...

Embodiment 3

[0045] (1) Preparation of nano zinc oxide wrapped by polydopamine:

[0046] After heating 50 parts by volume of 0.2 mol / L sodium hydroxide solution to 100°C, slowly add an equivalent amount of 0.1 mol / L zinc acetate solution under stirring conditions, and react at constant temperature for 30 minutes. The suspension was separated by filtration, and vacuum-dried at 100°C to obtain nano-zinc oxide;

[0047] 0.1 parts by mass of dopamine hydrochloride was dissolved in 0.05 mol / L Tris buffer solution of pH 8.5 to obtain a solution of dopamine hydrochloride with a mass fraction of 0.1%, and 1 part by mass of nano-zinc oxide was added, and the reaction was stirred at room temperature for 1 d. The suspension was separated by filtration, and vacuum-dried at 60°C to prepare polydopamine-coated nano-zinc oxide;

[0048] (2) Preparation of modified collagen:

[0049] 1 mass part of type I collagen was dissolved in 0.5 mol / L acetic acid solution to obtain a collagen solution with a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com