Method for removing hardness by using exhaust gas CO2

A CO2, waste gas technology, applied in chemical instruments and methods, water softening, water/sewage treatment, etc., can solve the problems of inconvenient waste water treatment and reuse, difficult sedimentation of particulate matter, low treatment efficiency, etc., to reduce the floor space. , The effect of reducing acid consumption and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

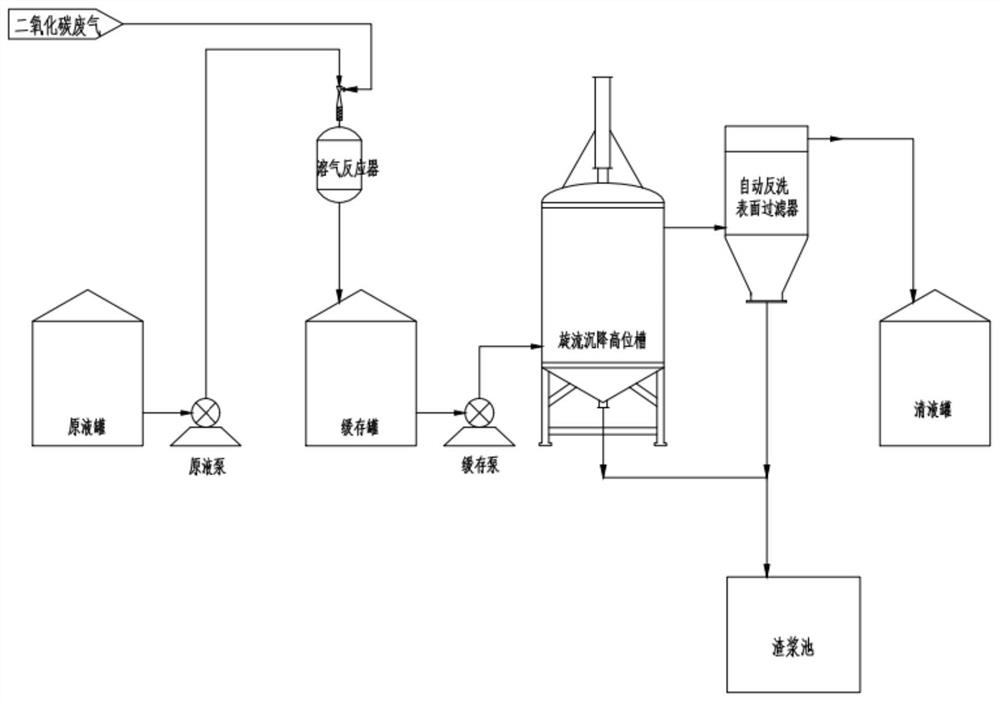

[0050] Such as figure 1 As shown, the original solution is transported from the original solution tank to the mixer (Venturi high-efficiency mixer) through the original solution pump, mixed with carbon dioxide waste gas, and then enters the dissolved gas reactor. The outlet of the device flows into the buffer tank, and is sent into the swirl settling high level tank through the buffer pump;

[0051] The fully reacted mixed liquid flows into the automatic backwash surface filter for solid-liquid separation, and the qualified clear liquid at the filter outlet enters the clear liquid tank.

[0052] The slurry produced by the swirl settling head tank (magnesium removal reactor, calcium removal reactor) and the automatic backwash surface filter is regularly discharged into the slurry pool.

specific Embodiment approach 2

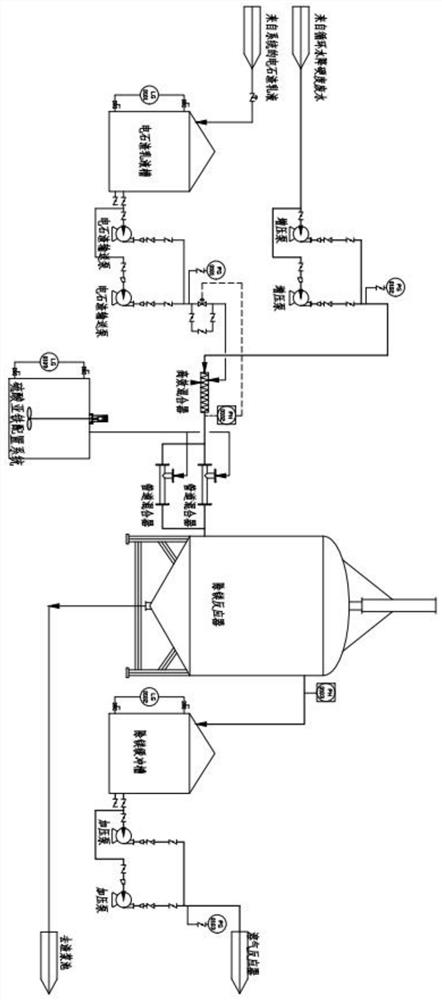

[0053] Such as figure 2 As shown, the calcium carbide slag emulsion from the system enters the carbide slag emulsion tank, enters the high-efficiency mixer through the carbide slag delivery pump, and at the same time, the wastewater from the circulation for hardness reduction enters the high-efficiency mixer through the booster pump, and the carbide slag emulsion and the circulation for hardness reduction The waste water is mixed into the pipeline mixer through a high-efficiency mixer. Two pipeline mixers are set in parallel and communicated with the magnesium removal reactor. One of the pipeline mixers is connected in series with the ferrous sulfate configuration system, and the solution passing through the pipeline mixer enters Ca(OH) in carbide slag solution in magnesium removal reactor 2 with Mg in circulating water 2+ After the chemical reaction is carried out to generate magnesium hydroxide, the supernatant of the magnesium removal reactor is collected into the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com