Process for preparing isooctene by selective superposition of mixed C4

A hybrid carbon four, selective technology, applied in the direction of hydrocarbons, hydrocarbons, carbon compound catalysts, etc., can solve the problem of low 1-butene catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

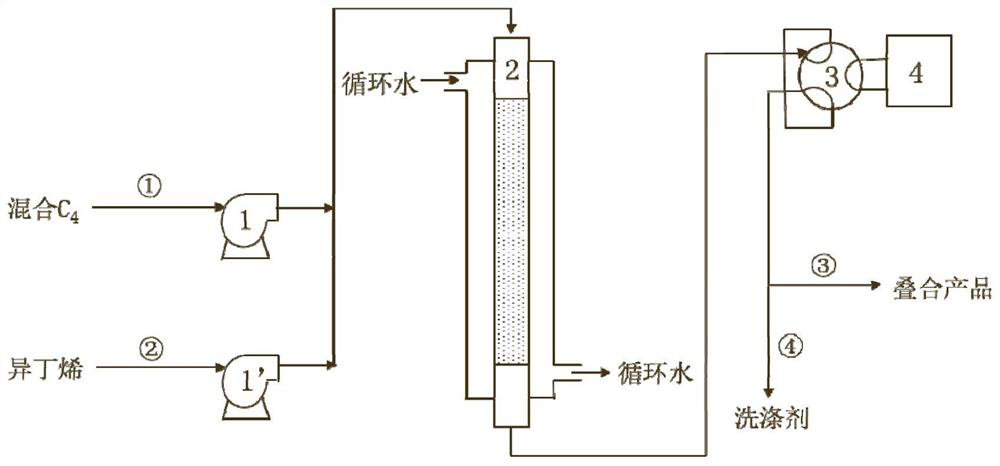

Method used

Image

Examples

preparation example Construction

[0042] According to the present invention, the preparation method of described Y type molecular sieve catalyst comprises:

[0043] (1) NaY molecular sieve and ammonium salt aqueous solution are subjected to ammonium ion exchange reaction to obtain NH 4 -Y type molecular sieve;

[0044] (2) NH 4 -Y-type molecular sieve is subjected to hydrothermal treatment to obtain ultra-stable Y-type molecular sieve;

[0045] (3) contacting the ultra-stable Y-type molecular sieve with oxoacid and ammonium oxoacid for acid treatment, then drying and roasting to obtain a modified HY-type molecular sieve;

[0046] (4) Mix the modified HY type molecular sieve and the alumina source to form a carrier mixture, and add nitric acid aqueous solution and scallop powder to the carrier mixture to make a slurry for extruding.

[0047] According to the present invention, desodium NH is obtained through the step (1) 4 - Molecular sieve of type Y, preferably such that said desodiumized NH 4 -Na of Y mo...

Embodiment 1

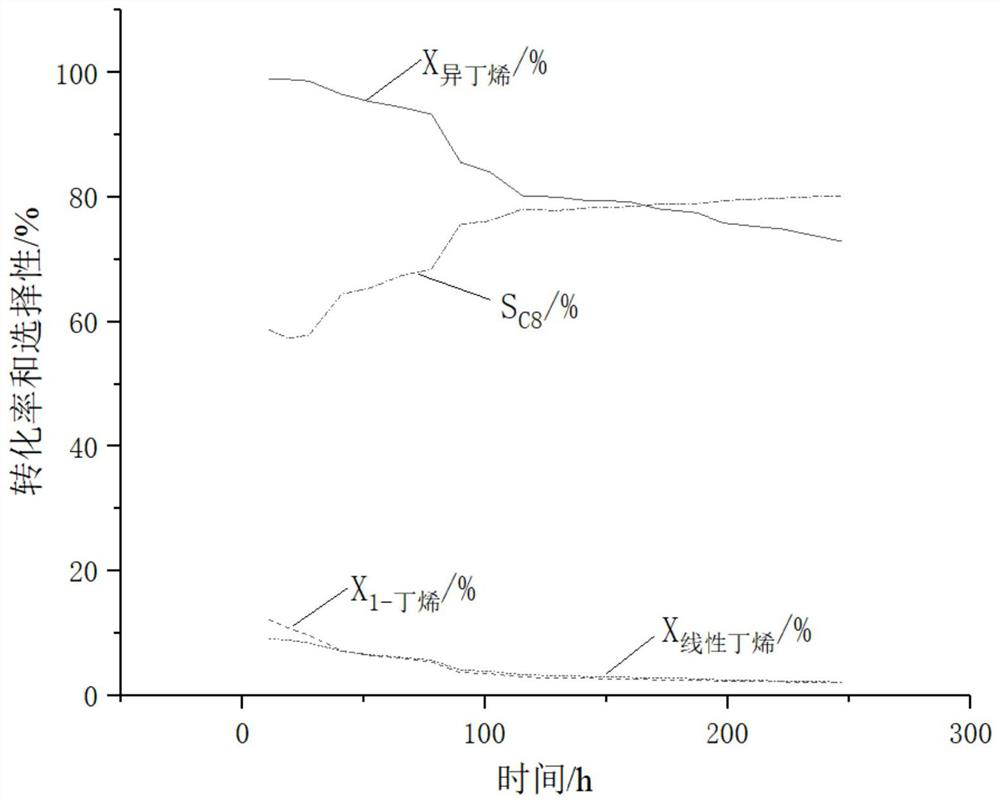

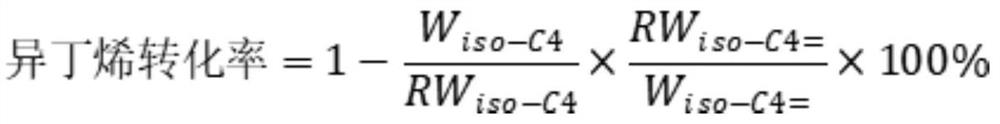

[0084] This example is used to illustrate the process for preparing isooctene by selective condensation of mixed carbon four provided by the present invention.

[0085] Weigh 120g NaY powder (SiO 2 / Al 2 o 3 The molar ratio is 5:1, Na 2 O content is 8% by weight), 60g NH 4 Mix Cl with 800g of water at room temperature, stir at 75°C for 3 hours and then filter; after suction filtration three times, add the filter residue to 800g of water, stir at 75°C for 3 hours and then filter, and repeat this operation twice. Put the obtained filter residue into a high-temperature hydrothermal treatment furnace for hydrothermal treatment. The temperature of the furnace is raised from room temperature to 550 °C at a rate of 10 °C / min, and the temperature is kept for 3 hours. The water vapor pressure in the furnace is controlled to 0.1 MPa. Add 12g oxalic acid and 18g ammonium oxalate to the molecular sieve after hydrothermal treatment and add 1.4L water to be configured into a 0.2mol / L ox...

Embodiment 2

[0093] This example is used to illustrate the process for preparing isooctene by selective condensation of mixed carbon four provided by the present invention.

[0094]Repeat the reaction in Example 1-deactivated catalyst washing and regeneration-reaction step 5 times, after the fifth washing and regeneration, the conversion rate of isobutene is 96.7%, the conversion rate of 1-butene is 5.4%, and the total conversion rate of butene is 45.3% %, the total conversion rate of linear butenes (1-butene, cis-2-butene, trans-2-butene) is 4.9%, and the selectivity of carbon octaolefins is 66.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com