Coupling agent oligomer for enhancing adhesive property and preparation method thereof

A technology of adhesive properties and oligomers, applied in the field of silane coupling agents, can solve the problems of affecting the service life of solar panels, reducing the efficiency of converting light energy into electrical energy, skin and eye irritation, etc., and achieving enhanced adhesion. , Extend the shelf life, improve the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

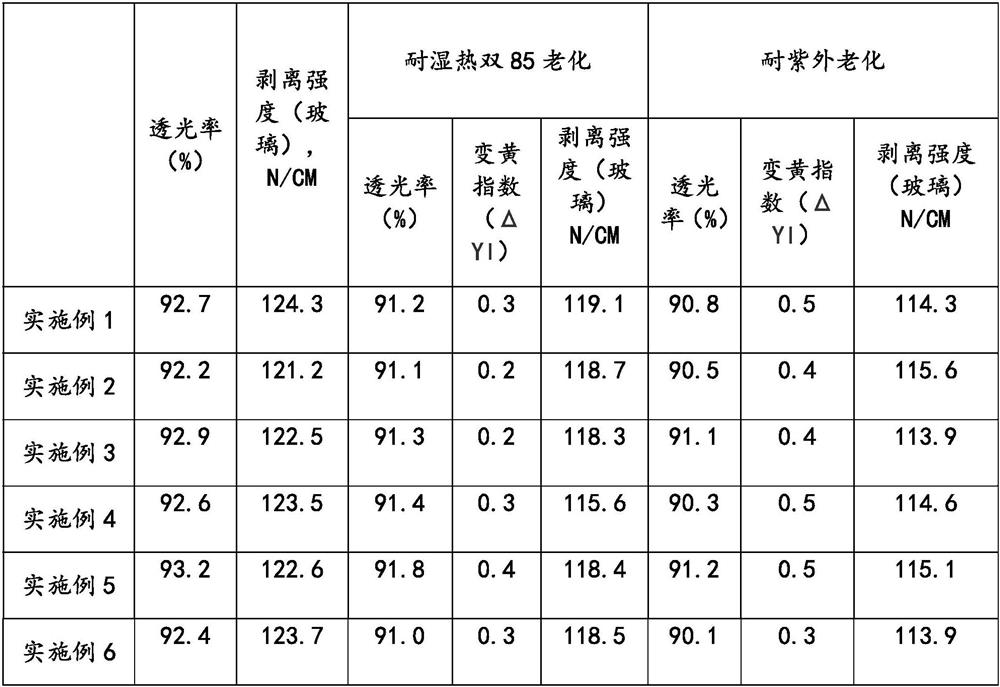

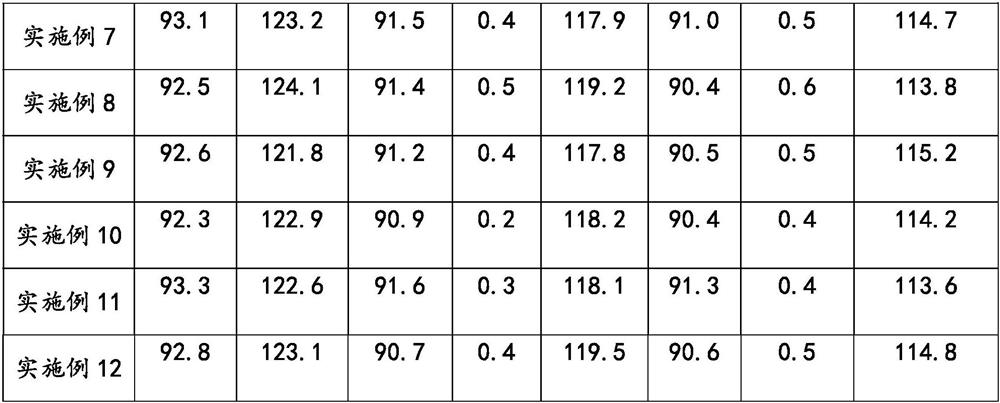

Examples

Embodiment 1

[0033] Add 150 g of solvent ethanol, 0.4 g of polymerization inhibitor 2,3,5,6-tetramethylphenol, and 36 % of concentrated hydrochloric acid catalyst 0.2g, γ-methacryloxypropyl trimethoxysilane 400g, after feeding, put the flask into the heating mantle for heating and stirring, put 40g ultrapure water and 80g solvent ethanol into the constant In the pressure funnel, when the temperature in the flask is 35°C, it starts to be evenly added dropwise into the four-necked flask, the temperature of the dropping process is not higher than 40°C, and the dropping time is 1h; the mixing of the ultrapure water and the first solvent The solution is added dropwise at a rate of 0.5s to 1s;

[0034]After the dropwise addition, keep warm at 35°C for 2 hours and then conduct moisture detection. When the moisture content is detected to be less than 1000ppm, slowly add neutralizing agent ammonia water to neutralize the catalyst in the system;

[0035] After cooling down to room temperature, remo...

Embodiment 2

[0037] Put 150 g of solvent toluene, 2 g of inhibitor hydroquinone, 0.3 g of catalyst formic acid, and γ-methylpropylene into a 1L four-necked flask equipped with a thermometer, a stirring bar, a reflux condenser, and a constant pressure dropping funnel device. Acyloxypropyltrimethoxysilane 400g, put the flask into the heating mantle for heating and stirring after feeding, put 40g ultrapure water and 80g solvent toluene into the constant pressure funnel, when the temperature in the flask is 30°C Start to evenly drop it into the four-necked flask, the temperature of the dropping process is not higher than 40°C, and the dropping time is 1h; the mixed solution of the ultrapure water and the first solvent is added dropwise at a rate of 0.5s to 1s;

[0038] After the dropwise addition, keep warm at 30°C for 3 hours and then conduct moisture detection. When the moisture content is detected to be less than 1000ppm, slowly add the neutralizing agent aluminum hydroxide to neutralize the...

Embodiment 3

[0041] Add 150 g of solvent methyl ethyl ketone, 1 g of polymerization inhibitor 2,3,5,6-tetramethylphenol, and a catalyst to a 1 L four-necked flask equipped with a thermometer, a stirring bar, a reflux condenser, and a constant pressure dropping funnel device. 0.4g of p-toluenesulfonic acid, 400g of γ-methacryloxypropyl trimethoxysilane, after feeding, put the flask into the heating mantle for heating and stirring, put 40g of ultrapure water and 60g of solvent methyl ethyl ketone into the constant In the pressure funnel, when the temperature in the flask is 40°C, it starts to be evenly added dropwise into the four-necked flask, the temperature of the dropping process is not higher than 40°C, and the dropping time is 0.5h; the ultrapure water and the first solvent The mixed solution is added dropwise at a rate of 0.5s to 1s;

[0042] After the dropwise addition, keep warm at 40°C for 2 hours and then conduct moisture detection. When the moisture content is detected to be less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap