Method for separating manganese from ternary lithium ion battery positive electrode leachate

A lithium-ion battery and leaching solution technology, applied in secondary batteries, battery recycling, circuits, etc., can solve the problems of less separation research, large space occupation, and long process flow, and achieve simple equipment requirements, small changes and differences, and shorten recycling The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

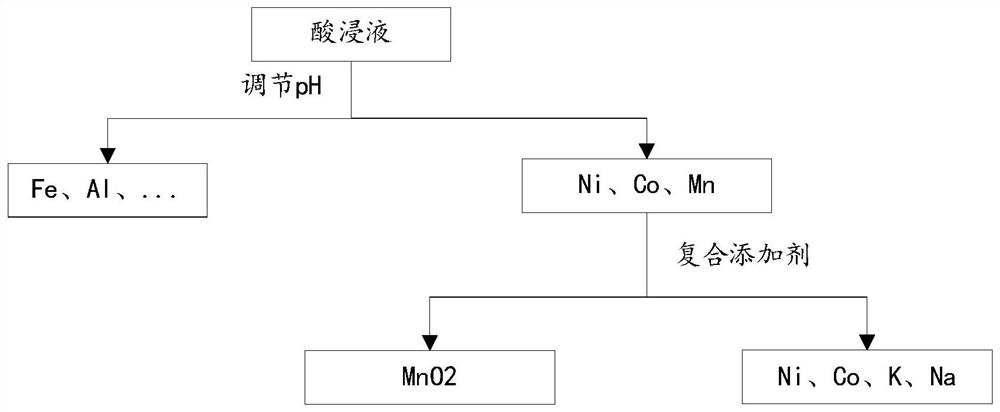

Method used

Image

Examples

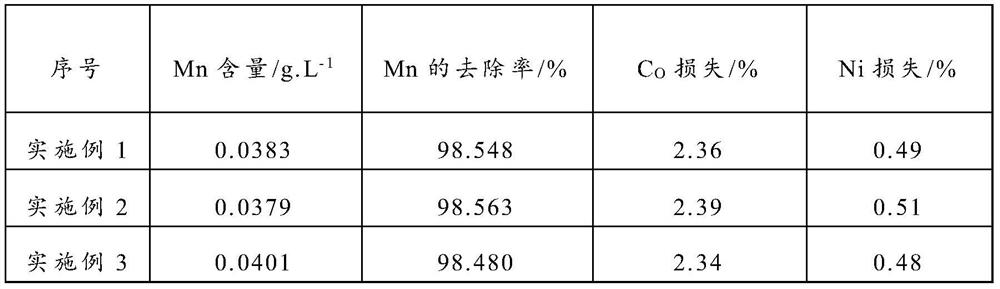

Embodiment 1

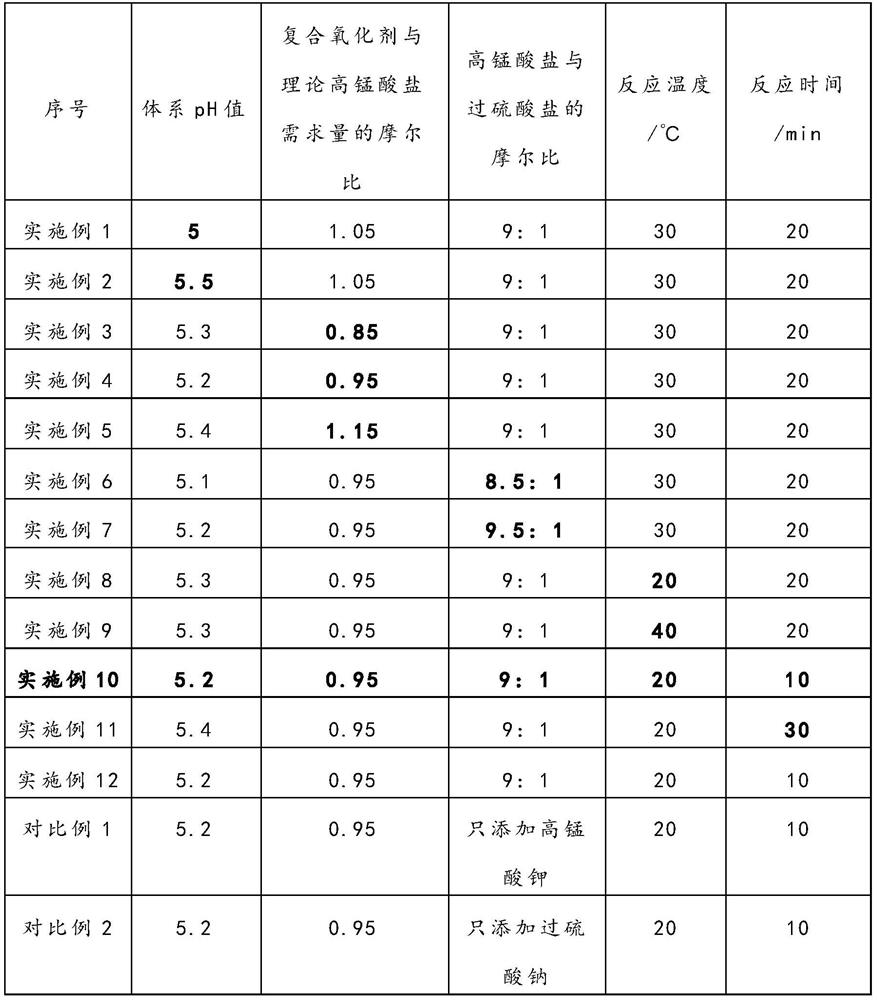

[0044] The method provided in this embodiment specifically includes the following steps:

[0045] A composite oxidant consisting of potassium permanganate and sodium persulfate is added to the positive electrode leaching solution of the above-mentioned lithium ion battery to make the Mn 2+ Oxidation reaction occurs, and the MnO 2 form precipitation, remove the manganese element in the leaching solution, and analyze and detect the residual manganese, cobalt and nickel content in the supernatant.

[0046] Wherein, the addition amount of the composite additive is 1.05 times of the theoretical value of the molar amount of potassium permanganate, and the molar ratio of potassium permanganate and sodium persulfate in the composite additive is 9:1.

[0047] During the oxidation reaction, the pH of the solution was 5, the temperature was 30° C., and the reaction time was 20 minutes.

Embodiment 2

[0049] The method provided in this embodiment specifically includes the following steps:

[0050] A composite oxidant consisting of potassium permanganate and sodium persulfate is added to the positive electrode leaching solution of the above-mentioned lithium ion battery to make the Mn 2+ Oxidation reaction occurs, and the MnO 2 form precipitation, remove the manganese element in the leaching solution, and analyze and detect the residual manganese, cobalt and nickel content in the supernatant.

[0051] Wherein, the addition amount of the composite additive is 1.05 times of the theoretical value of the molar amount of potassium permanganate, and the molar ratio of potassium permanganate and sodium persulfate in the composite additive is 9:1.

[0052] During the oxidation reaction, the pH of the solution was 5.5, the temperature was 30° C., and the reaction time was 20 minutes.

Embodiment 3

[0054] The method provided in this embodiment specifically includes the following steps:

[0055] A composite oxidant consisting of potassium permanganate and sodium persulfate is added to the positive electrode leaching solution of the above-mentioned lithium ion battery to make the Mn 2+ Oxidation reaction occurs, and the MnO 2 form precipitation, remove the manganese element in the leaching solution, and analyze and detect the residual manganese, cobalt and nickel content in the supernatant.

[0056] Wherein, the addition amount of the composite additive is 0.85 times of the theoretical value of the molar amount of potassium permanganate, and the molar ratio of potassium permanganate and sodium persulfate in the composite additive is 9:1.

[0057] During the oxidation reaction, the pH of the solution was 5.3, the temperature was 30° C., and the reaction time was 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com