Cold-rolled stainless steel annealing and pickling process, and pickling equipment

A cold-rolled stainless steel, pickling technology, applied in heat treatment equipment, metal material coating process, manufacturing tools, etc., can solve the problems of high acid consumption, high power consumption, speed up cleaning speed, etc., to reduce acid temperature, improve Pickling efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a cold-rolled stainless steel annealing and pickling process. The pickling process allows the high-temperature strip to directly enter the pickling tank for pickling by controlling the temperature of the strip steel at the exit of the annealing furnace, and cancels the drying device at the exit of the annealing furnace. Descaling process and mechanical brushing device in the pickling section, and through the cascade overflow continuous pickling process system without nitric acid and hydrofluoric acid, the rapid cleaning of strip steel can be realized, and energy consumption and acid consumption can be reduced at the same time to obtain high surface quality The strip steel specifically comprises the following steps:

[0027] Step 1), after the cold-rolled stainless steel enters the annealing furnace to adjust the composition, by adjusting the cooling capacity of the cooling section of the annealing furnace, the temperature of the cold-rolled stain...

Embodiment 2

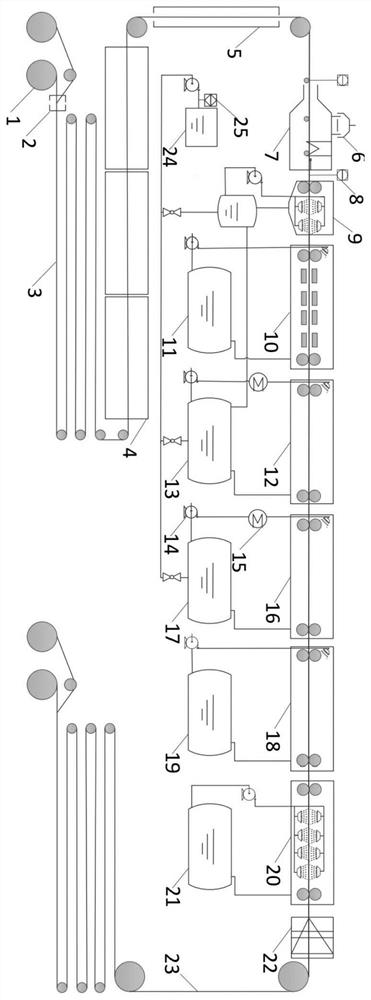

[0040] refer to figure 1 , which is a kind of pickling equipment for realizing the cold-rolled stainless steel annealing pickling process of the above-mentioned embodiment 1, including a strip steel conveying device (not shown in the figure) and uncoilers arranged in sequence along the traveling direction of the strip steel 23 Machine 1, welding machine 2, looper 3, annealing furnace 4, heat preservation chamber 5, temperature control device, pre-cleaning tank 9, electrolytic tank 10, 1# acid tank 12, 2# acid tank 16, passivation tank 18, rinse tank 20 and dryer 22.

[0041] Among them, the temperature control device is provided with a fan 6 and a heater 7, the temperature of the strip steel can be regulated by controlling the power of the fan and heater 7, and a plate temperature instrument 8 is also installed on the temperature control device to detect and control the temperature of the strip steel. Steel plate temperature; electrolyte circulation tank 11 is connected to el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com