Antibacterial and antifouling composite fabric and processing technology thereof

A technology of composite fabrics and processing technology, applied in the direction of improved hand-feeling fibers, synthetic resin layered products, lamination, etc., can solve the problems of less composite fabrics, easy breeding of bacteria, poor resistance to dirt, etc., and achieve improved antibacterial Ability, improve antifouling ability, improve hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

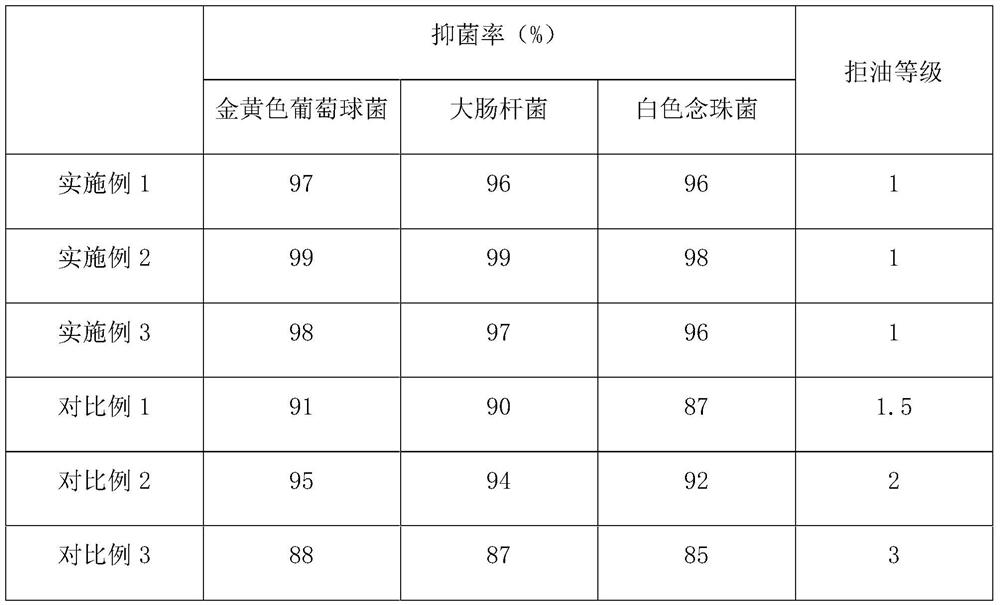

Examples

Embodiment 1

[0038] (1) Prepare the inner fabric:

[0039] a1. Preparation of finishing agent:

[0040] In a nitrogen atmosphere, mix double-terminated epoxycarbonyl polysiloxane and diethylenetriamine, add isopropanol, and heat up to 75°C for 4 hours to obtain amino-containing polysiloxane;

[0041] Mix toluene diisocyanate, polyester polyol, polyethylene glycol, and dibutyl dilauric acid, heat up to 80°C and react for 160 minutes; add 1,4-butanediol, dimethylol butyric acid, and sodium azide , 2,2-Dimethylolpropionic acid, react for 6 hours and cool down to 40°C; slowly add diethanolamine, react for 40 minutes, and obtain a polyurethane prepolymer;

[0042] Take polyurethane prepolymer and amino-containing polysiloxane, add emulsifier and deionized water, adjust the pH of the system to 6.5, and cut for 15 minutes; add silk peptide and cuprous bromide to mix, and react for 1 hour to prepare a finishing agent;

[0043] b1. Preparation of inner fabric:

[0044] Take the finishing agent p...

Embodiment 2

[0054] (1) Prepare the inner fabric:

[0055] a1. Preparation of finishing agent:

[0056] In a nitrogen atmosphere, mix double-ended epoxycarbonylpolysiloxane and diethylenetriamine, add isopropanol, heat up to 77°C and react for 4.5h to obtain amino-containing polysiloxane;

[0057] Take toluene diisocyanate, polyester polyol, polyethylene glycol, and dibutyl dilauric acid and mix them, raise the temperature to 82°C and react for 180 minutes; add 1,4-butanediol, dimethylol butyric acid, and sodium azide , 2,2-Dimethylolpropionic acid, react for 6.5h and cool down to 42°C; slowly add diethanolamine, react for 42min to obtain polyurethane prepolymer;

[0058] Take polyurethane prepolymer and amino-containing polysiloxane, add emulsifier and deionized water, adjust the pH of the system to 6, cut for 15 minutes; add silk peptide and cuprous bromide to mix, react for 2 hours, and prepare the finishing agent;

[0059] b1. Preparation of inner fabric:

[0060]Take the finishing ...

Embodiment 3

[0070] (1) Prepare the inner fabric:

[0071] a1. Preparation of finishing agent:

[0072] In a nitrogen atmosphere, mix double-ended epoxycarbonylpolysiloxane and diethylenetriamine, add isopropanol, heat up to 80°C and react for 5 hours to obtain amino-containing polysiloxane;

[0073] Mix toluene diisocyanate, polyester polyol, polyethylene glycol, and dibutyl dilauric acid, heat up to 85°C and react for 200 minutes; add 1,4-butanediol, dimethylol butyric acid, and sodium azide , 2,2-Dimethylolpropionic acid, after 7 hours of reaction, cool down to 45°C; slowly add diethanolamine, and react for 45 minutes to obtain a polyurethane prepolymer;

[0074] Take polyurethane prepolymer and amino-containing polysiloxane, add emulsifier and deionized water, adjust the pH of the system to 7, cut for 15 minutes; add silk peptide and cuprous bromide to mix, react for 3 hours, and prepare the finishing agent;

[0075] b1. Preparation of inner fabric:

[0076] Take the finishing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com