Method for preparing nanoscale high-performance Nd2Fe14B/MnBi composite magnet material

A nd2fe14b, composite magnet technology, applied in the direction of magnetic materials, magnetic objects, inductance/transformer/magnet manufacturing, etc., to achieve the effect of suppressing structural deformities, high surface, and high magnetic energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

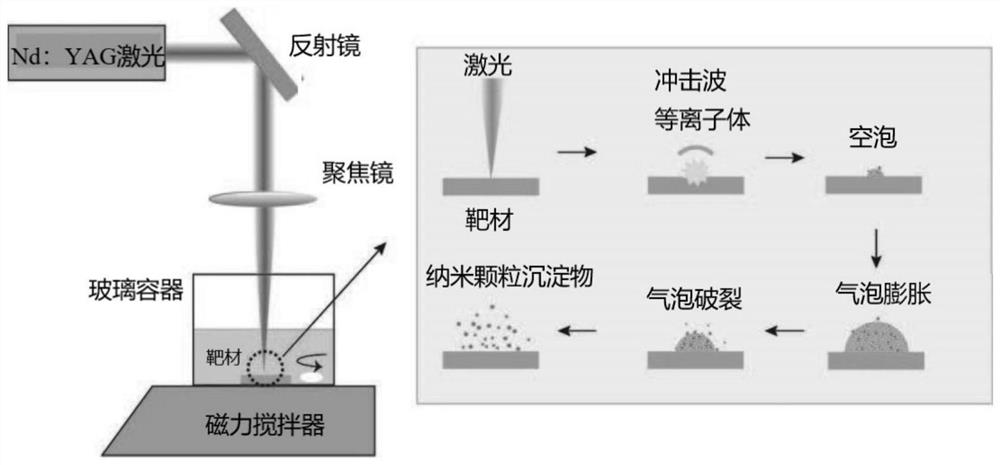

[0026] A method for preparing a nanoscale composite magnet material by a liquid-phase laser ablation method comprises the following steps:

[0027] (1) Batching stage: the atomic number ratio is Nd: Dy: Fe: Nb: Co: B = 9: 0.4: 80.24: 0.36: 3: 6, convert the atomic number ratio into a mass ratio, and then weigh the metal Powder materials Nd, Dy, Tb, In, Fe, Co, FeB (the mass fraction of B in FeB is 19.83%) and NbFe (the mass fraction of Nb in NbFe is 66.3%), and then add the finished MnBi (atoms of Mn and Bi The number ratio is 54:46) After the powder is fully ground and mixed, the raw material powder is pressed into a block with a length of 15mm, a width of 15mm, and a thickness of 4mm under a pressure of 15Mpa;

[0028] (2) Pre-burning stage: the pressed block is heated at 1050 o C pre-burned for 4 hours to form a precursor;

[0029] (3) Ablation stage: the temperature of the precursor is lowered to room temperature, and the precursor is cleaned with an ultrasonic cleaning ...

Embodiment 2

[0033] A method for preparing a nanoscale composite magnet material by a liquid-phase laser ablation method comprises the following steps:

[0034] (1) Dosing stage: atomic ratio: Nd: Dy: Fe: Nb: Co: B=9: 0.4: 80.24: 0.36: 3: 6, convert the atomic number ratio into mass ratio, and then weigh the metal powder material Nd, Dy, Tb, In, Fe, Co, FeB (the mass fraction of B in FeB is 19.83%) and NbFe (the mass fraction of Nb in NbFe is 66.3%), and then add the finished MnBi (the atomic number ratio of Mn and Bi 54:46) After the powder is fully ground and mixed, the raw material powder is pressed into a block with a length of 12mm, a width of 15mm, and a thickness of 6mm under a pressure of 15Mpa;

[0035] (2) Pre-burning stage: the pressed block is heated at 1050 o C pre-burned for 4 hours to form a precursor;

[0036] (3) Ablation stage: the temperature of the precursor is lowered to room temperature, and the precursor is cleaned with an ultrasonic cleaning agent for 30 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com