Water flushing slag industrial waste gas treatment device

A technology for industrial waste gas and treatment equipment, which is applied in the direction of heating equipment, dispersed particle filtration, lighting and heating equipment, etc. It can solve the problems that waste gas cannot cool down liquid water, etc., and achieve the effect of heat transfer, dryness maintenance and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

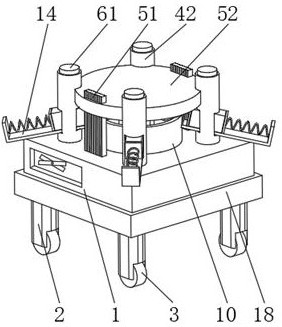

[0037] see Figure 1-7 , the present invention provides a technical solution: an industrial waste gas treatment device for water flushing slag, including a limit frame 1, a support leg 2 is symmetrically installed on the bottom of the limit frame 1, and a roller 3 is installed on the bottom of the support leg 2, and the position limit The external settings for box 1 are:

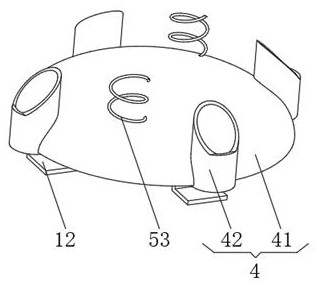

[0038] Cooling device 4, the cooling device 4 has a heat conduction plate 41, the top of the heat conduction plate 41 is symmetrically installed with a vent pipe 42, the vent pipe 42 runs through the heat conduction plate 41 and extends to the bottom of the heat conduction plate 41, and the top end of the vent pipe 42 runs through the limit frame 1 and extends to the top of the limit frame 1;

[0039] The heat conduction device 5, the heat conduction device 5 has a heat conduction plate 51, the top end of the heat conduction plate 51 extends to the top of the limit frame 1 and is equipped with a heat collec...

Embodiment 2

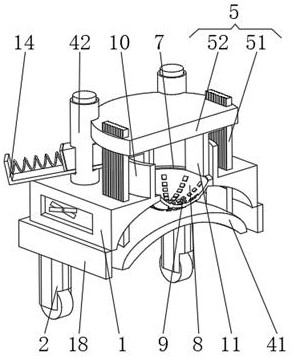

[0046] see Figure 1-7 , the present invention provides a technical solution: on the basis of Embodiment 1, a heat-conducting groove 7 is provided on the top of the limiting frame 1, and a heat-resistant film 8 is installed inside the heat-conducting groove 7, and the top of the heat-resistant film 8 is filled with water , the bottom of the heat-resistant film 8 is uniformly installed with a metal sheet 9 , and the metal sheet 9 penetrates the heat-resistant film 8 and extends to the outside of the heat-resistant film 8 .

[0047] The top of the limiting frame 1 is fixedly connected with a water retaining ring 10 near the position of the heat conduction groove 7, and both sides of the inner wall of the water retaining ring 10 are fixedly connected with a support frame 11, and the top of the support frame 11 is fixedly connected with the heat collecting plate 52.

[0048] One side of the air pipe 42 is fixedly connected with a track frame 14 , the track frame 14 runs through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com