Mineral processing technology for removing sesquioxide from collophanite through intermediate grading retreatment

A technology of sesquioxide and collophosphate, which is used in flotation, solid separation, etc., and can solve the problems of poor sorting, large dosage of cationic reverse flotation, and high foam viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

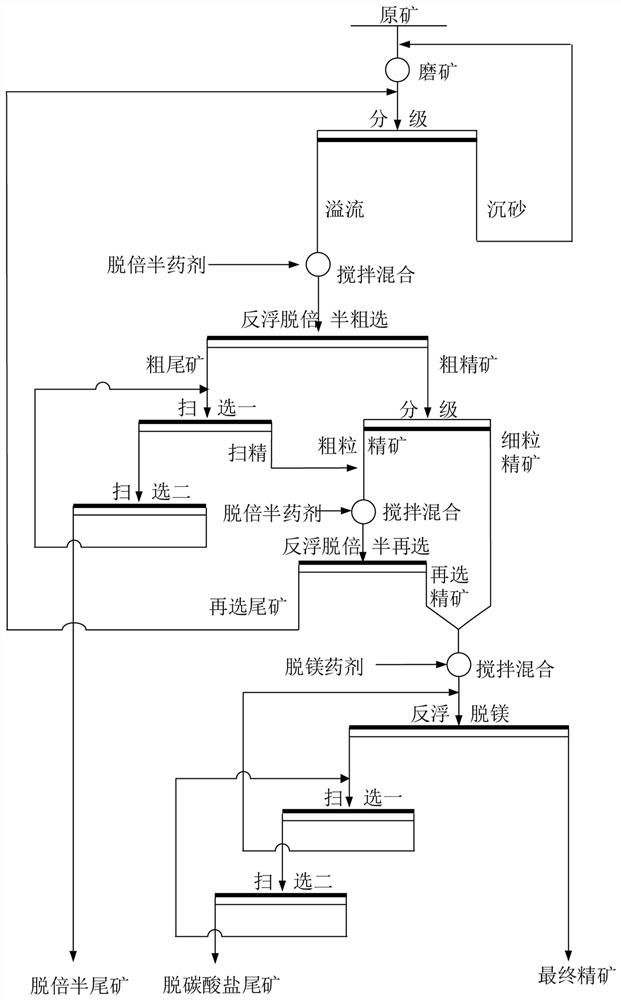

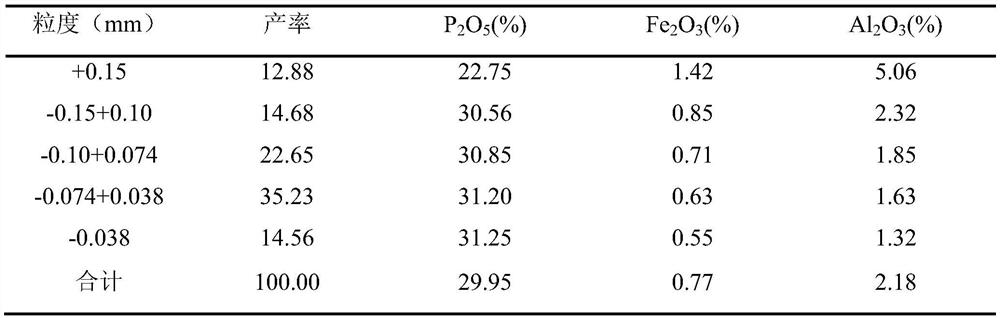

[0053] This example rubber phosphorus oreland ore P 2 O 5 The taste is 24.32%, the half oxide R 2 O 3 (Fe 2 O 3 + Al 2 O 3 The content of 7.18%, MgO content is 2.02%; the milling, the grading overflow concentration is 35%, and the particle size of the overflow is less than 0.074 mm in the overflow accounts for 53%. At this time, the particle size is less than 0.038 mm, which accounts for 16%, and the monomer dissolution 74%; in the process of intermediate grading and re-processing, the hydrogen production process, the process of process figure 1 The specific process steps are as follows:

[0054] (1) After mixing the original mine mill and the grading, the cationic capture is mixed, and the amount of cationic capping is 200g / T is 200g / T prototype (according to the original ore routine write) to obtain a coarse And coarse tailings; where cationic capture is c 10 Alkylpropyl ether amine is in the recuperator product of the acetic acid, and the neutralization is 60%.

[0055] (2)...

Embodiment 1-1

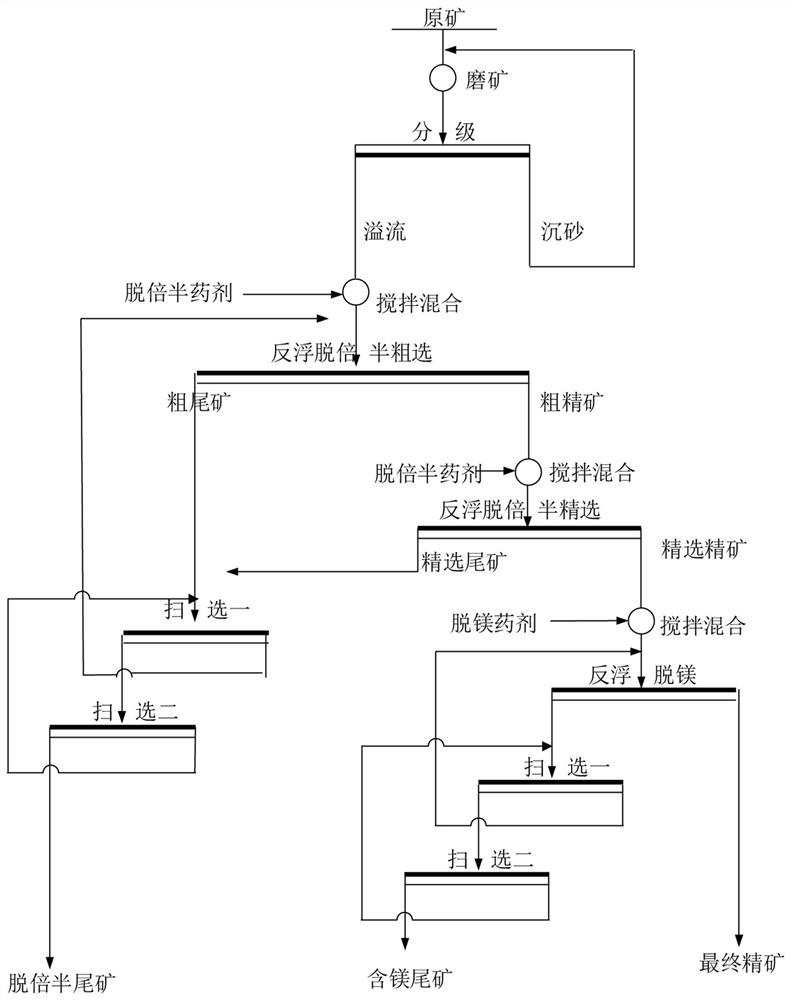

[0063] This example rubber phosphorus oreland ore P 2 O 5 The taste is 24.32%, the half oxide R 2 O 3 (Fe 2 O 3 + Al 2 O 3 The content of 7.18%, MgO content is 2.02%; the milling, the grading overflow concentration is 35%, and the particle size of the overflow is less than 0.074 mm in the overflow accounts for 53%. At this time, the particle size is less than 0.038 mm, which accounts for 16%, and the monomer dissolution 74%; no intermediate grading directly carry out clastped semi-oxide distribution process, process flow figure 2 The specific process steps are as follows:

[0064] (1) After mixing the original mine mill and the grading, the cationic collector is mixed, and the cationic capture deposit is supplied in 200g / T of the ore, and the coarse selection and coarse selection is obtained; where Cationic capture agent is C 10 Alkylpropyl ether amine is in the recuperator product of the acetic acid, and the neutralization is 60%.

[0065] (2) A cationic capture agent 150 g / t...

Embodiment 1-2

[0070] This example rubber phosphorus oreland ore P 2 O 5 The taste is 24.32%, the half oxide R 2 O 3 (Fe 2 O 3 + Al 2 O 3 The content of 7.18%, MgO content is 2.02%; the milling, the grading overflow concentration is 35%, and the particle size of the overflow is less than 0.074 mm in the overflow accounts for 53%. At this time, the particle size is less than 0.038 mm, which accounts for 16%, and the monomer dissolution 74%; in the process of intermediate grading and re-processing, the hydrogen production process, the process of process figure 1 The specific process steps are as follows:

[0071] (1) After mixing the original mine mill and the grading, the cationic collector is mixed, and the cationic capture deposit is supplied in 200g / T of the ore, and the coarse selection and coarse selection is obtained; where Cationic capture agent is C 10 Alkylpropyl ether amine is in the recuperator product of the acetic acid, and the neutralization is 60%.

[0072] (2) Screened the coars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com