Preparation method and application method of vigorous growth control fertilizer

An application method and fertilizer technology, which is applied in the field of preparation of Konwang fertilizer, can solve problems such as high safety technical requirements, impact on yield and quality, and long residual time of ingredients, and achieve the effect of expanding molecular spectrum, ensuring effect, and suppressing top advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

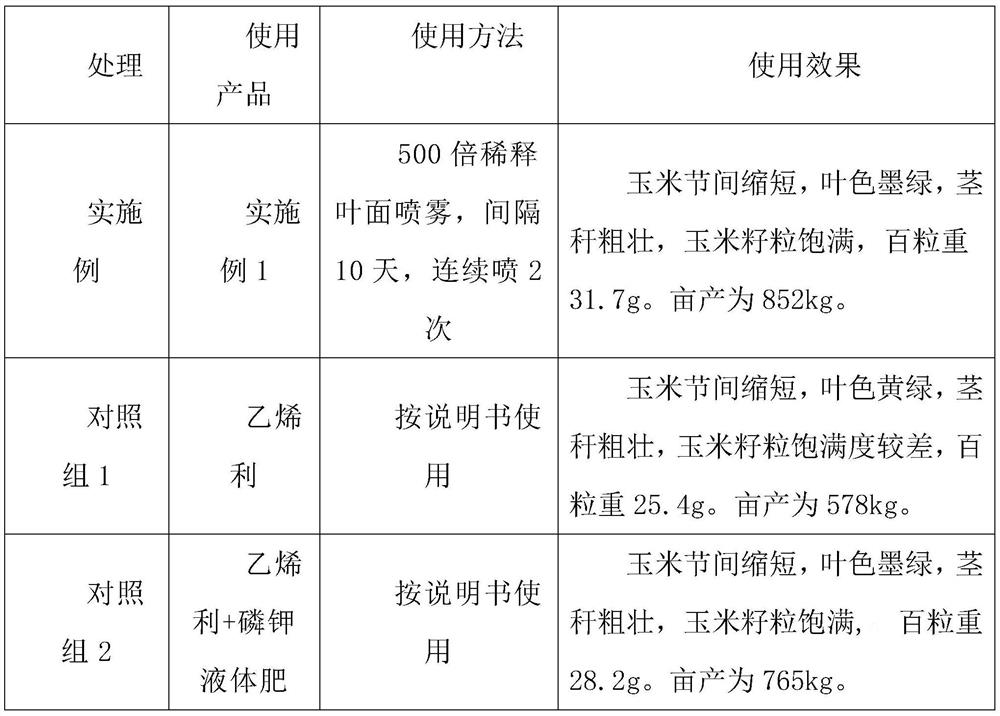

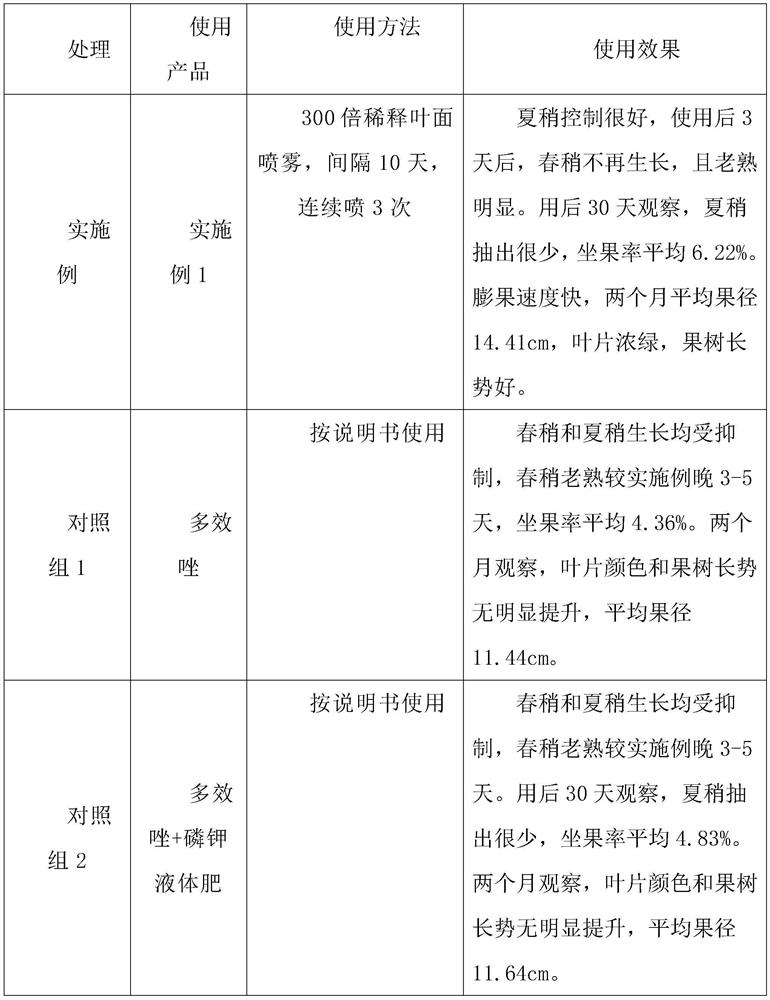

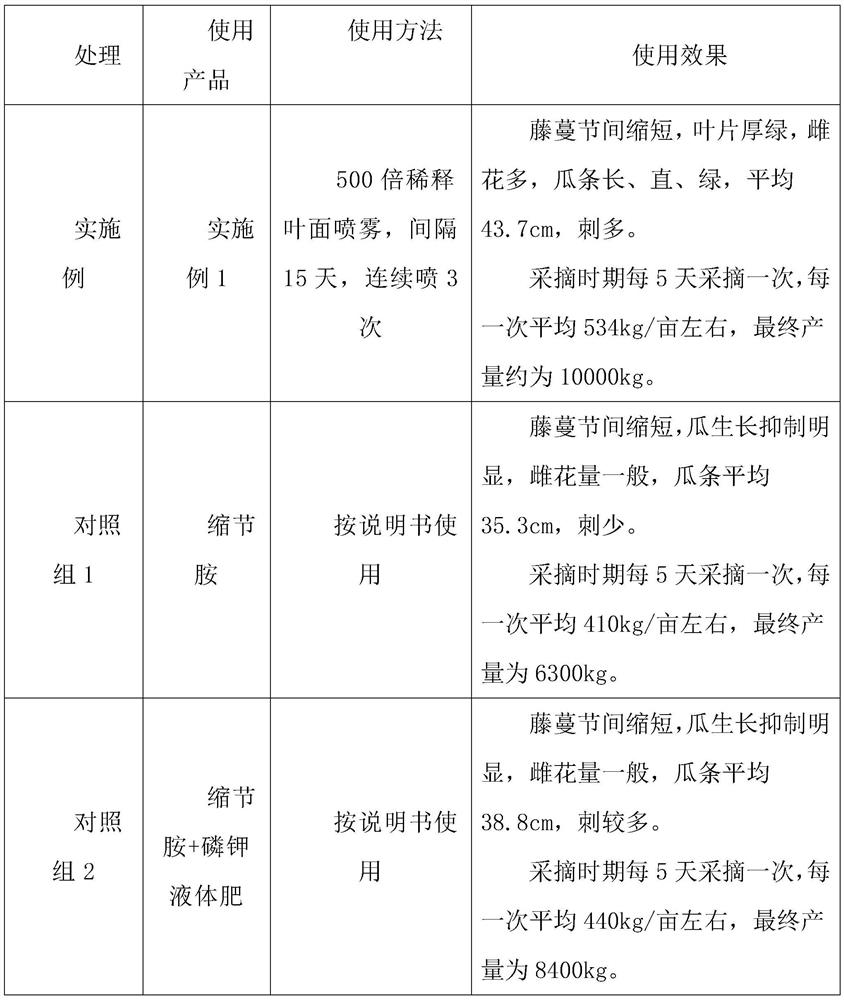

Examples

Embodiment 1

[0024] In a 1000L fermenter, add 600kg of water, and then add Spartina alterniflora and Hedyotis diffusa with a ratio of 9:1 and 80kg of crushed and mixed materials (calculated on a dry basis), according to 1:1:4:9:2: Magnesium sulfate, calcium carbonate, sodium chloride, glucose, soybean protein powder, potassium dihydrogen phosphate, defoamer and other fermentation auxiliary materials were added at a ratio of 1:1. The total mass of fermentation auxiliary materials was 0.5kg, and sterilized at 121°C for 30 minutes. Cool to 35°C, inoculate Bacillus subtilis (auxotroph), control the temperature at 35°C, the ventilation rate is 0.7m3 / min, and the stirring speed is 120 rpm. Ferment for 8 hours, reduce the ventilation rate to 0.5m3 / min, and add 2kg of sterilized DL-malic acid every 5 minutes, adding 40kg in total. After 20 hours of fermentation, the aeration volume was restored to 0.7m3 / min. Ferment for 24 hours, take a sample every half hour to observe the growth of the bacteria...

Embodiment 2

[0031] In a 1000L fermenter, add 600kg of water, and then add Spartina alterniflora and Hedyotis diffusa with a ratio of 9:1 and 80kg of crushed and mixed materials (calculated on a dry basis), according to 1:1:4:9:2: Magnesium sulfate, calcium carbonate, sodium chloride, glucose, soybean protein powder, potassium dihydrogen phosphate, defoamer and other fermentation auxiliary materials were added at a ratio of 1:1. The total mass of fermentation auxiliary materials was 0.5kg, and sterilized at 125°C for 25 minutes. Cool to 35°C, inoculate Bacillus subtilis (auxotroph), control the temperature at 35°C, the ventilation rate is 0.7m3 / min, and the stirring speed is 120 rpm. Ferment for 8 hours, reduce the ventilation rate to 0.5m3 / min, and add 2kg of sterilized DL-malic acid every 5 minutes, adding 40kg in total. After 20 hours of fermentation, the aeration volume was restored to 0.7m3 / min. Ferment for 24 hours, take a sample every half hour to observe the growth of the bacteria...

Embodiment 3

[0039]In a 1000L fermenter, add 600kg of water, and then add Spartina alterniflora and Hedyotis diffusa with a ratio of 9:1 and 80kg of crushed and mixed materials (calculated on a dry basis), according to 1:1:4:9:2: Magnesium sulfate, calcium carbonate, sodium chloride, glucose, soybean protein powder, potassium dihydrogen phosphate, defoamer and other fermentation auxiliary materials were added at a ratio of 1:1. The total mass of fermentation auxiliary materials was 0.5kg, and sterilized at 115°C for 30 minutes. Cool to 35°C, inoculate Bacillus subtilis (auxotroph), control the temperature at 35°C, the ventilation rate is 0.7m3 / min, and the stirring speed is 120 rpm. Ferment for 8 hours, reduce the ventilation rate to 0.5m3 / min, and add 2kg of sterilized DL-malic acid every 5 minutes, adding 40kg in total. After 20 hours of fermentation, the aeration volume was restored to 0.7m3 / min. Ferment for 24 hours, take a sample every half hour to observe the growth of the bacteria,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com