Recycling method of waste composite insulator in power industry, polypropylene/silicone rubber composite material and preparation method of polypropylene/silicone rubber composite material

A composite insulator and a technology in the power industry, applied in the field of silicone rubber, can solve the problems of difficult recycling, low mechanical strength, low impact strength, etc., and achieve the effects of increasing recycling value, improving mechanical properties, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

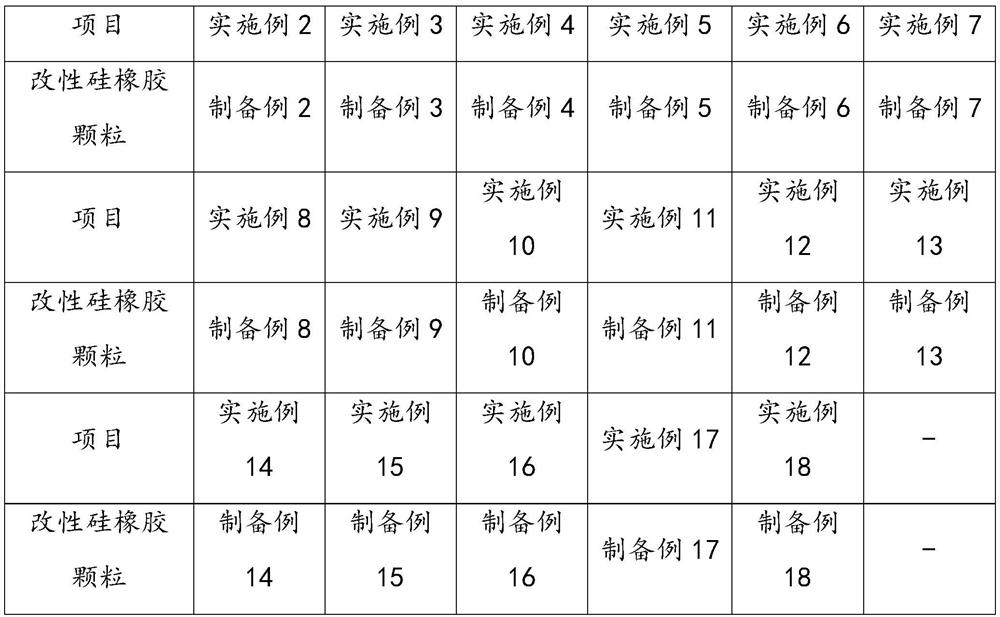

Examples

preparation example 1

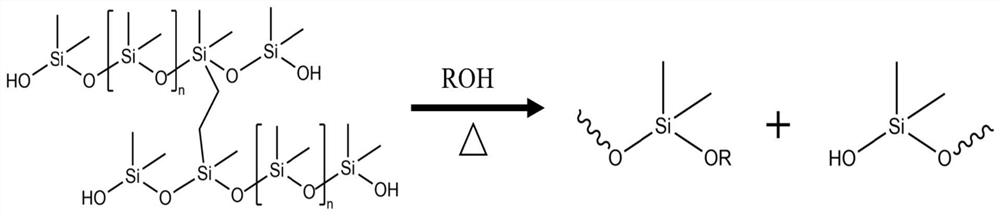

[0032] A method for recycling waste composite insulators in the power industry, specifically comprising the following steps:

[0033] S01. Use the crushing equipment to crush the waste composite insulator silicone rubber into silicon rubber particles, and the particle size after crushing is 80 mesh;

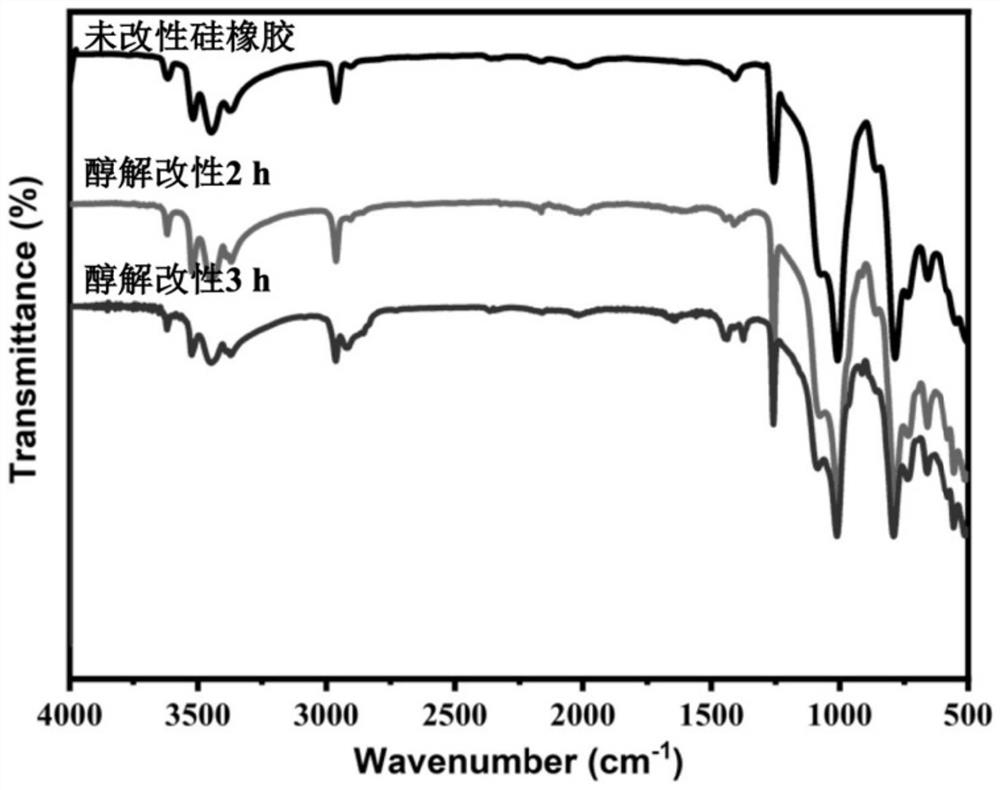

[0034] S02. Mix 50g of silicone rubber particles with 100g of 3,7-dimethyl-2,6-octadien-1-ol, and after standing for 24 hours, carry out high-temperature alcoholysis reaction in a pressure vessel, controlling the reaction temperature to 220°C , the control reaction time is 2h;

[0035] S03. After the reaction is finished, wash with ethanol solvent and dry to obtain modified silicone rubber particles.

preparation example 2

[0037] A method for recycling waste composite insulators in the electric power industry. Each step and the reagents and parameters used in each step are the same as those in Preparation Example 1, except that in S02, the reaction time of the high-temperature alcoholysis reaction is 2.5h.

preparation example 3

[0039] A method for recycling waste composite insulators in the electric power industry. Each step and the reagents and parameters used in each step are the same as those in Preparation Example 1, except that in S02, the reaction time of the high-temperature alcoholysis reaction is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com