Production technology of moisture-absorbing, quick-drying, one-way moisture-conducting and high-elastic fabric

A moisture-conducting, high-elasticity, moisture-absorbing and quick-drying technology, applied in the field of high-elasticity fabrics, can solve problems such as environmental hazards, environmental pollution, and inability to withstand multiple washings, and achieve the effects of simple preparation process, safety and environmental protection in the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

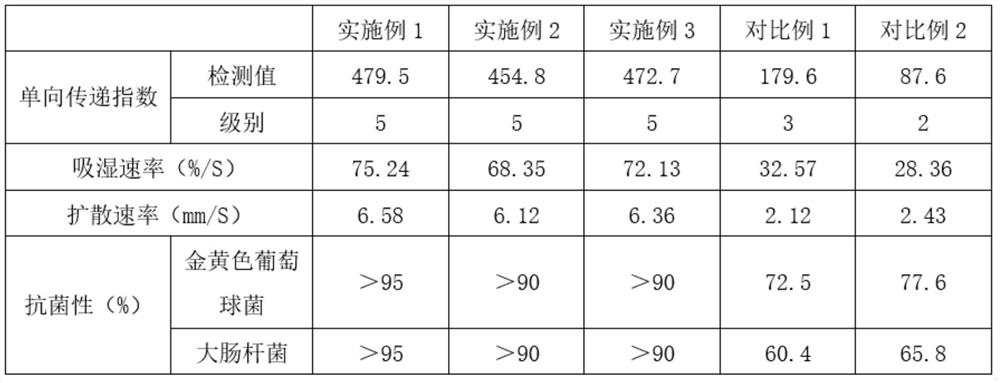

Examples

Embodiment 1

[0044] A production process for moisture-absorbing and quick-drying unidirectional moisture-conducting high-elastic fabrics, comprising the following steps:

[0046] Using moisture-conducting polyester fiber and cotton fiber according to the weight ratio of 3:1, after pretreatment, stretching into slivers, and then sequentially drawing, stretching, carding and twisting into yarns to obtain surface warp and surface weft;

[0047] Waterproof polyester fiber and polyurethane fiber are pretreated according to the weight ratio of 6:1.2, stretched into slivers, and then sequentially drawn, stretched, carded and then twisted into yarns to obtain inner warp and inner weft Wherein, the waterproof polyester fiber is obtained after finishing the polyester fiber with a silicone fluorine-free water repellant with a concentration of 60g / L;

[0048] Step 2, weaving the fabric:

[0049] Weaving using the joint binding method, that is, in the process of weavin...

Embodiment 2

[0062] Using moisture-conducting polyester fiber and cotton fiber according to the weight ratio of 2:1, after pretreatment, stretching into slivers, and then sequentially drawing, stretching, carding and twisting into yarns to obtain surface warp and surface weft;

[0063] Waterproof polyester fiber and polyurethane fiber are pretreated according to the weight ratio of 6:0.5 and stretched into slivers, and then drawn, stretched, carded and then twisted into yarns to obtain inner warp and inner weft Wherein, the waterproof polyester fiber is obtained after finishing the polyester fiber with an acrylic ester fluorine-free water repellant with a concentration of 10 / L;

[0064] Step 2, weaving the fabric:

[0065] Weaving using the joint binding method, that is, in the process of weaving the surface warp and surface weft to form the surface layer, the inner warp is lifted and interwoven with the surface weft at the same time, and in the process of weaving the inner warp and inner ...

Embodiment 3

[0078] Using moisture-conducting polyester fiber and cotton fiber according to the weight ratio of 4:1, after pretreatment, stretching into slivers, and then sequentially drawing, stretching, carding and twisting into yarns to obtain surface warp and surface weft;

[0079] Waterproof polyester fiber and polyurethane fiber are pretreated according to the weight ratio of 6:1.5 and stretched into slivers, and then drawn, stretched, carded and then twisted into yarns to obtain inner warp and inner weft Wherein, the waterproof polyester fiber is obtained after finishing the polyester fiber with a silicone fluorine-free water repellent with a concentration of 100g / L;

[0080] Step 2, weaving the fabric:

[0081] Weaving using the joint binding method, that is, in the process of weaving the surface warp and surface weft to form the surface layer, the inner warp is lifted and interwoven with the surface weft at the same time, and in the process of weaving the inner warp and inner weft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com