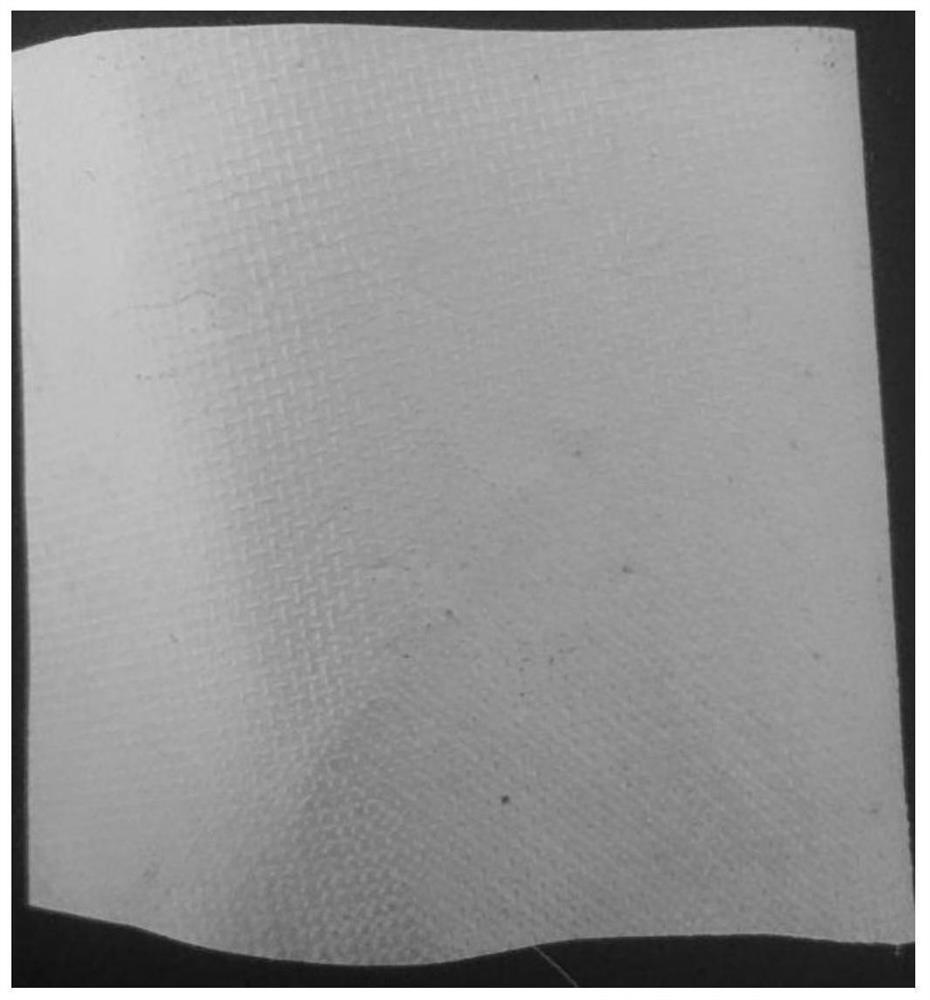

Polyimide composite nanofiber membrane with sandwich structure and preparation method thereof

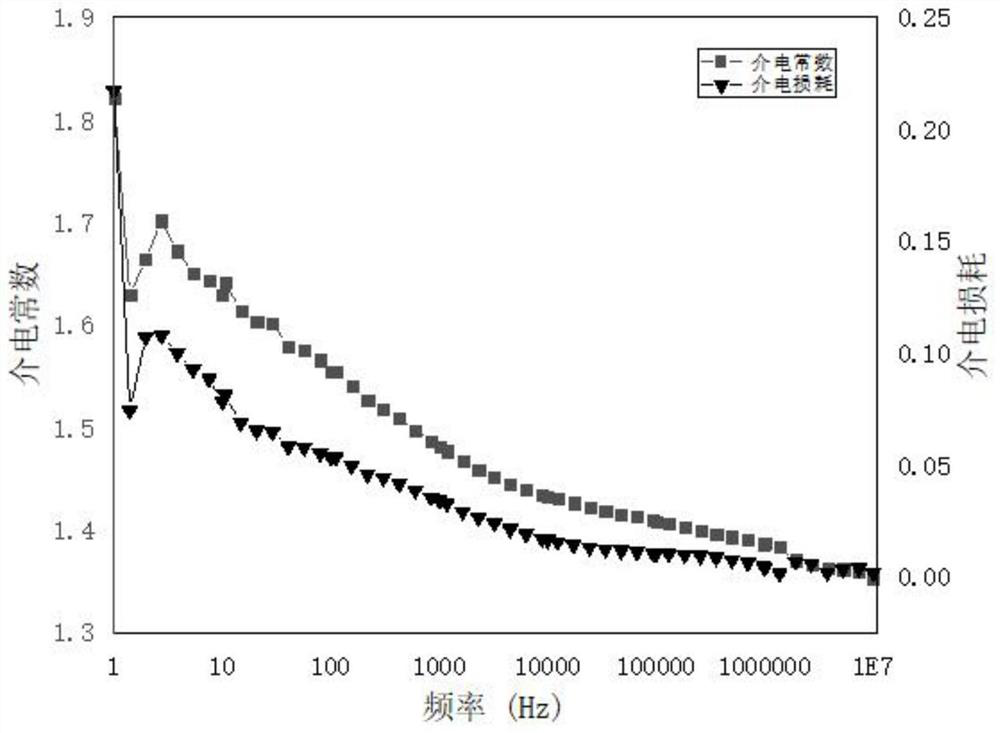

A technology of composite nanofibers and nanofiber membranes, applied in fiber treatment, nanotechnology, nanotechnology, etc., can solve problems such as high water absorption rate and decreased dielectric constant, so as to improve deterioration, reduce dielectric constant, and excellent durability hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

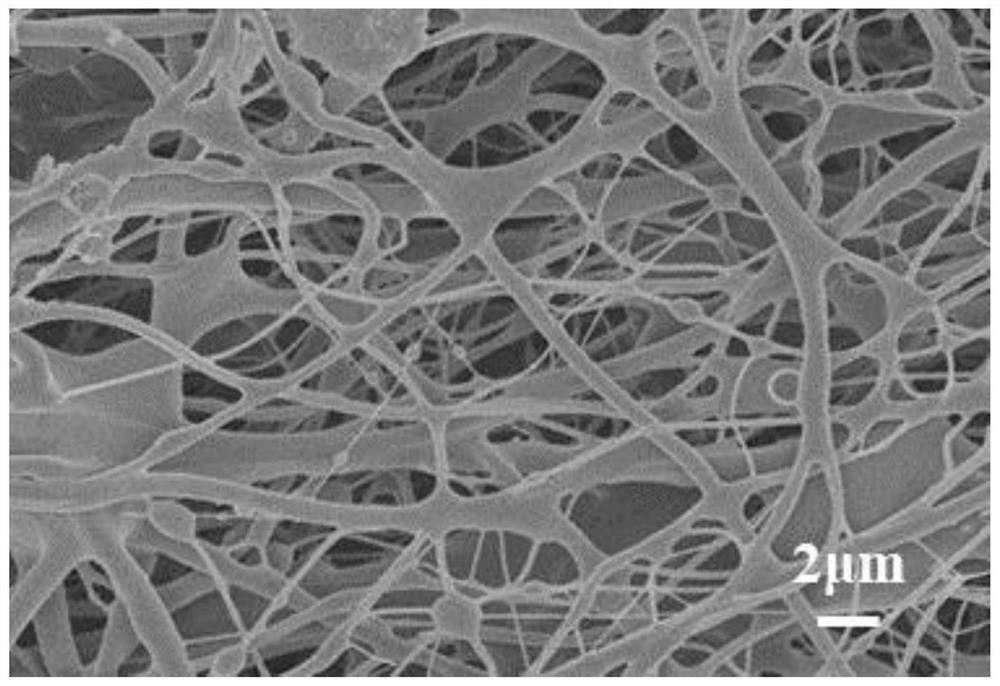

[0033] 1) Dissolve 20 g of polyimide acid in 20 g of DMAC solution, heat and stir at 80° C. for 30 min, until completely mixed uniformly, to obtain polyimide acid spinning solution. Take 0.6g polytetrafluoroethylene micro-nano powder, 0.6g polyvinylidene fluoride micro-powder, 4.4g DMF, 4.4g acetone, first mix DMF and acetone evenly, then add polytetrafluoroethylene micro-nano powder and polyvinylidene fluoride in turn Finely powdered, stirred at room temperature for 3 hours, and thoroughly mixed to obtain a polytetrafluoroethylene-polyvinylidene fluoride spinning solution.

[0034] 2) Using an electrospinning device, first spin 4mL polyimide acid solution to make an electrospun membrane, and then directly electrospin 4mL polytetrafluoroethylene-polyvinylidene fluoride mixed solution on the polyimide electrospun membrane Finally, 4 mL of polyimide acid solution was spun into an electrospun membrane to obtain a composite membrane with a sandwich structure. Among them, the spin...

Embodiment 2

[0038] 1) Dissolve 20 g of polyimide acid in 20 g of DMAC solution, heat and stir at 80° C. for 30 min, until completely mixed uniformly, to obtain polyimide acid spinning solution. Take 0.6g polytetrafluoroethylene micro-nano powder, 0.6g polyvinylidene fluoride micro-powder, 4.4g DMF, 4.4g acetone, first mix DMF and acetone evenly, then add polytetrafluoroethylene micro-nano powder and polyvinylidene fluoride in turn Finely powdered, stirred at room temperature for 3 hours, and thoroughly mixed to obtain a polytetrafluoroethylene-polyvinylidene fluoride spinning solution.

[0039] 2) Using an electrospinning device, first spin 4mL polyimide acid solution to make an electrospun membrane, and then directly electrospin 2mL polytetrafluoroethylene-polyvinylidene fluoride mixed solution on the polyimide electrospun membrane Finally, 4 mL of polyimide acid solution was spun into an electrospun membrane to obtain a composite membrane with a sandwich structure. Among them, the spin...

Embodiment 3

[0043] 1) Dissolve 20 g of polyimide acid in 20 g of DMAC solution, heat and stir at 80° C. for 30 min, until completely mixed uniformly, to obtain polyimide acid spinning solution. Take 0.6g polytetrafluoroethylene micro-nano powder, 0.6g polyvinylidene fluoride micro-powder, 4.4g DMF, 4.4g acetone, first mix DMF and acetone evenly, then add polytetrafluoroethylene micro-nano powder and polyvinylidene fluoride in turn Finely powdered, stirred at room temperature for 3 hours, and thoroughly mixed to obtain a polytetrafluoroethylene-polyvinylidene fluoride spinning solution.

[0044] 2) Using an electrospinning device, first spin 4mL polyimide acid solution to make an electrospun membrane, and then directly electrospin 8mL polytetrafluoroethylene-polyvinylidene fluoride mixed solution on the polyimide electrospun membrane Finally, 4 mL of polyimide acid solution was spun into an electrospun membrane to obtain a composite membrane with a sandwich structure. Among them, the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com