Magnetic biochar adsorbent prepared from sorghum straws as well as preparation method and application thereof

A technology of sorghum straw and biochar, which is applied in the field of resource utilization of agricultural waste and sewage treatment, can solve the problems of low recovery efficiency of biochar adsorbents, poor recycling effect, complicated preparation steps, etc., and achieve high-value resource utilization The effect of utilization, low cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

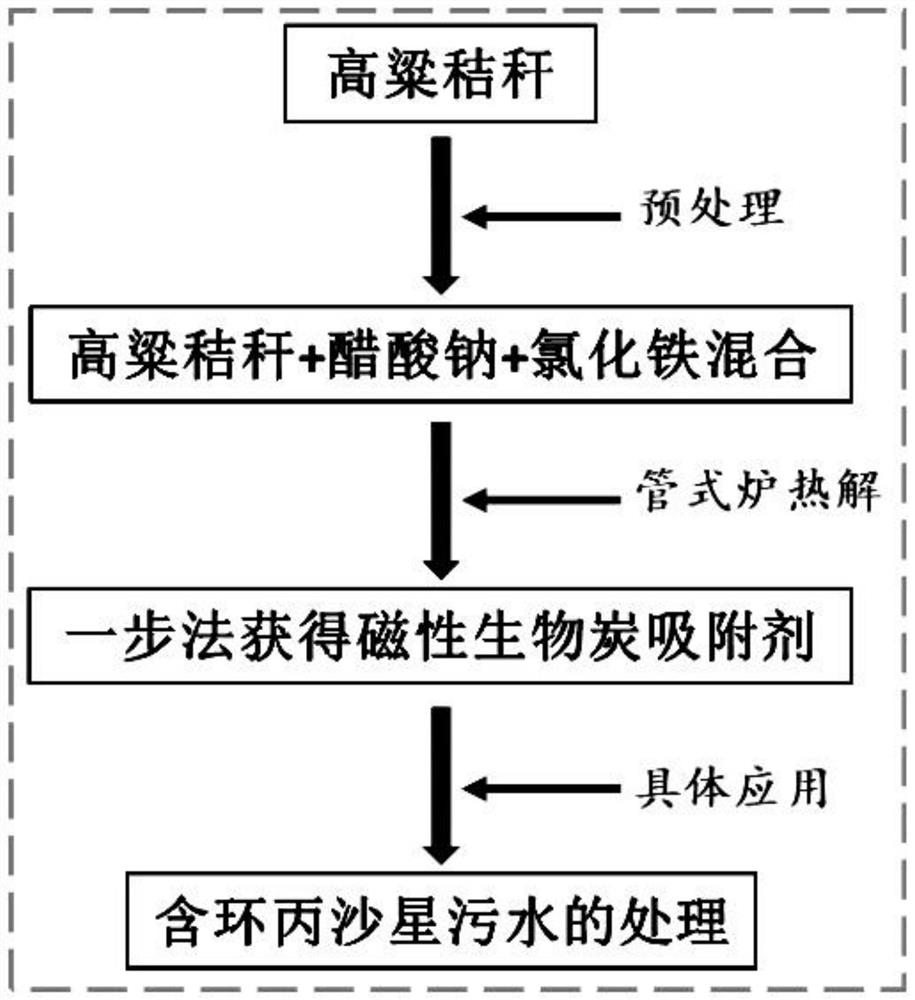

[0027] Such as figure 1 Shown is the preparation method and application of the sorghum stalk-based magnetic biochar adsorbent in the present invention, and its specific preparation steps:

[0028] 1. Wash the sorghum stalks, dry them at a temperature of 105±2° C. to constant weight, crush them through a 20-100 mesh sieve, and obtain the original samples of sorghum stalks.

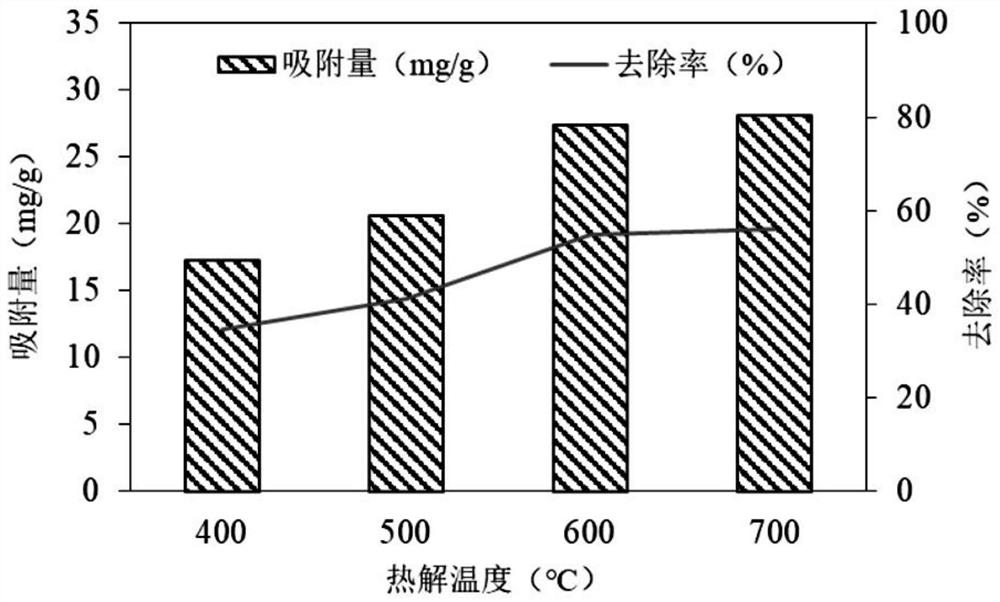

[0029] 2. Take 20g of the original sample of sorghum straw obtained in the above steps, place it in a 150mL crucible, put the crucible into a tube furnace, and mix the original sample of sorghum straw, sodium acetate, and ferric chloride in a ratio of 1:2:1. Mix, under the full protection of nitrogen, heat at a heating rate of 20°C / min to the set pyrolysis temperature t, the carbonization temperature is 400-700°C, and the pyrolysis time is 1.0h. After cooling, crush it with a pulverizer for 5 minutes to obtain fine Granular magnetic biomass adsorbent.

[0030] In this example, four pyrolysis temperatures ...

Embodiment 2

[0039] Such as figure 1 Shown is the preparation method and application of the sorghum stalk-based magnetic biochar adsorbent in the present invention, and its specific preparation steps:

[0040] 1. Wash the sorghum stalks, dry them at a temperature of 105±2° C. to constant weight, crush them through a 20-100 mesh sieve, and obtain the original samples of sorghum stalks.

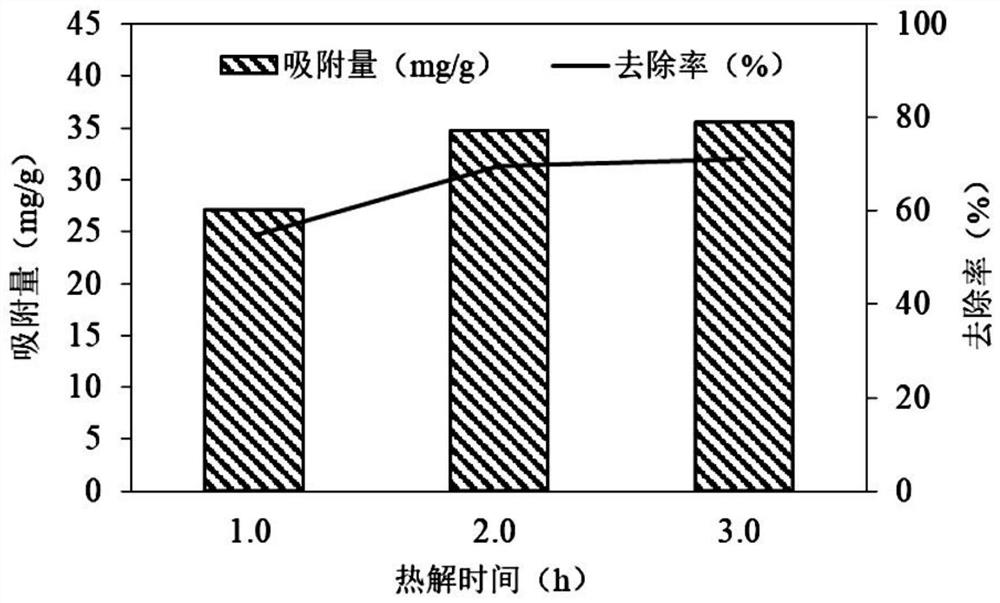

[0041] 2. Take 20g of the original sample of sorghum straw obtained in the above steps, place it in a 150mL crucible, put the crucible into a tube furnace, and mix the original sample of sorghum straw, sodium acetate, and ferric chloride in a ratio of 1:2:1. Mix, under the full protection of nitrogen, heat at a heating rate of 20°C / min to the set temperature of 600°C, pyrolysis and carbonization time t (1.0~3.0h), after cooling, crush with a pulverizer for 5 minutes to obtain fine particles of magnetic raw materials. material adsorbent.

[0042] In this example, three pyrolysis times are set to explore the ...

Embodiment 3

[0050] Such as figure 1 Shown is the preparation method and application of the sorghum stalk-based magnetic biochar adsorbent in the present invention, and its specific preparation steps:

[0051] 1. Wash the sorghum stalks, dry them at a temperature of 105±2° C. to constant weight, crush them through a 20-100 mesh sieve, and obtain the original samples of sorghum stalks.

[0052] 2. Take 20g of the original sample of sorghum straw obtained in the above steps, place it in a 150mL crucible, put the crucible into a tube furnace, and mix the original sample of sorghum straw, sodium acetate, and ferric chloride in a ratio of 1:2:1. Mixing, under the full protection of nitrogen, heating at a heating rate of 20°C / min to the set temperature of 600°C, pyrolysis and carbonization time of 2.0h, after cooling, pulverize with a pulverizer for 5 minutes to obtain a fine-grained magnetic biomass adsorbent.

[0053] 3. Prepare nine 100mL centrifuge tubes, weigh a certain amount of adsorbent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com