Preparation method of wine filtering and upgrading material based on natural sodium bentonite

A sodium-based bentonite and bentonite technology, applied in the preparation of alcoholic beverages, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of low secondary utilization rate of activated carbon for wine, large waste, and Problems such as high production cost, to achieve the effect of promoting wine body harmony, simple process, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

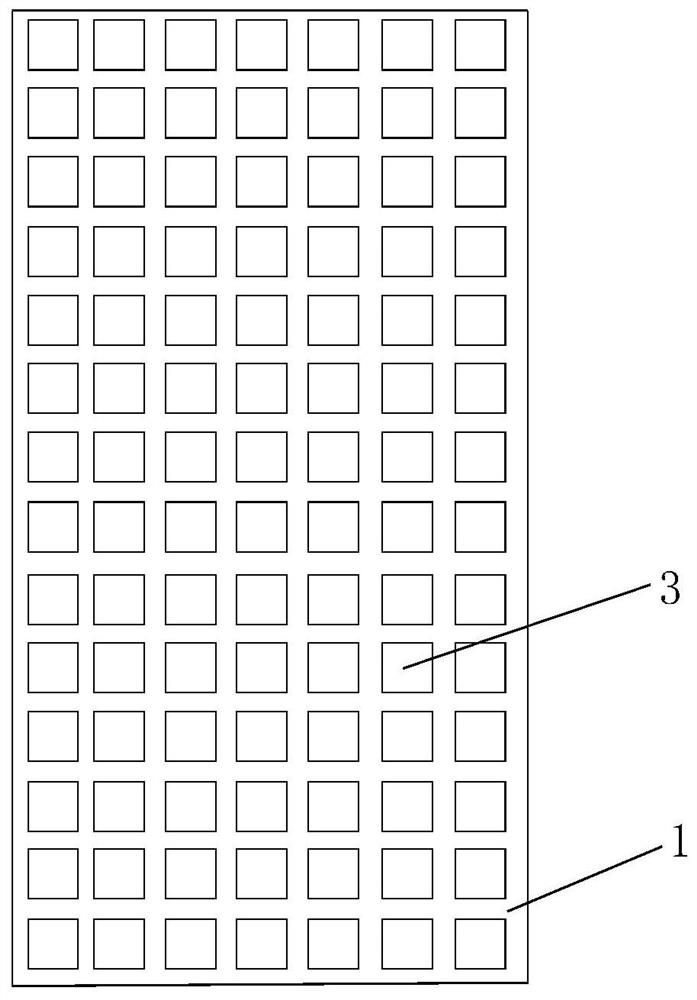

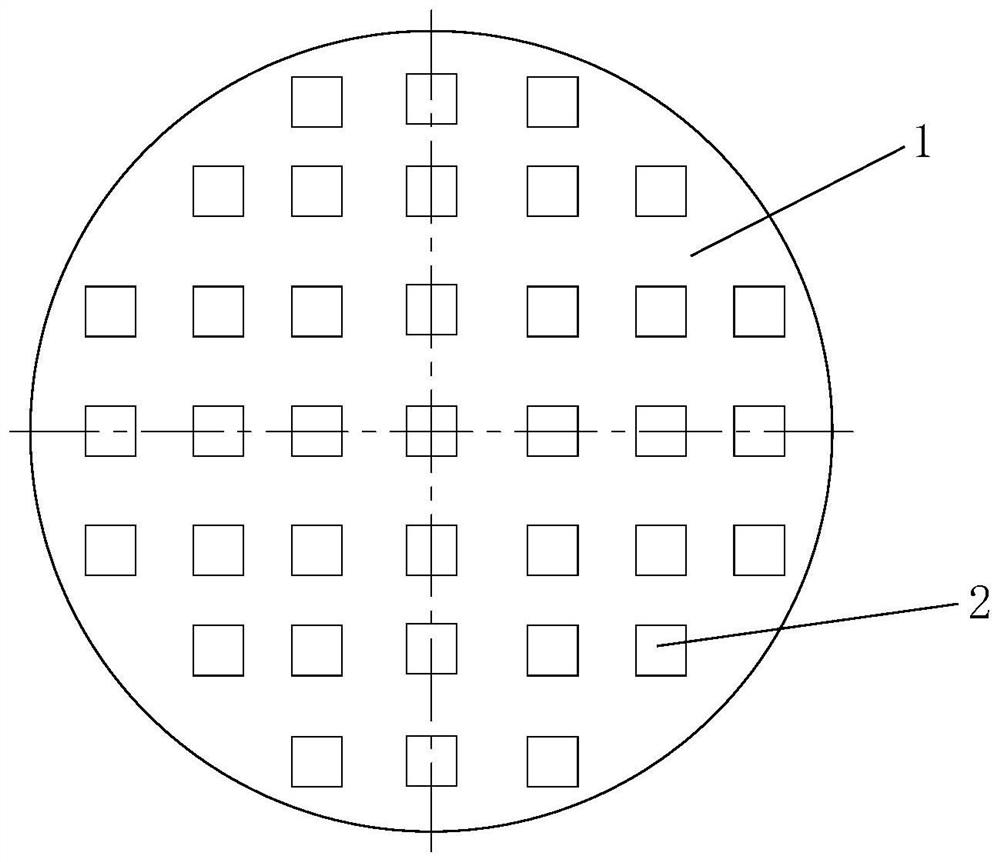

Image

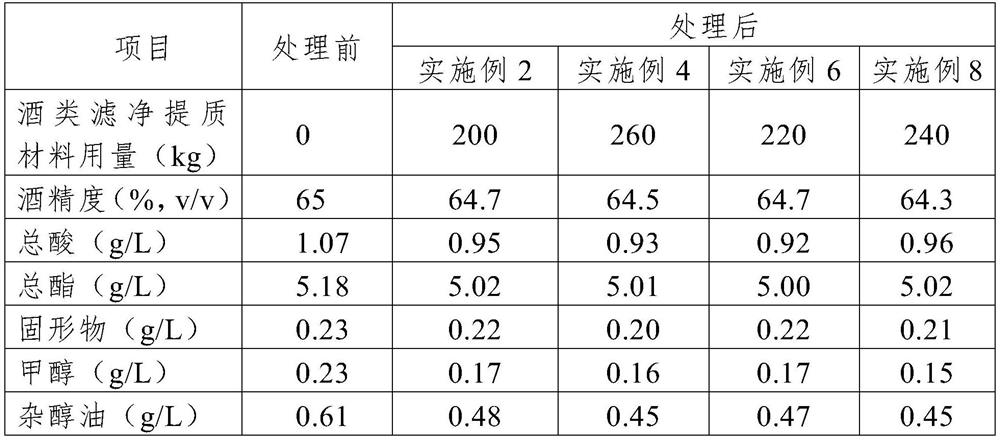

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

[0035] Step 1, preparation of bentonite raw material: pass natural sodium-based bentonite through a 220-mesh sieve, take the undersize, wash the undersize with distilled water several times to remove impurities, and obtain washed bentonite; place the washed bentonite in an oven at Dry for 24 hours under the condition of 100°C, and control the water content of the washed bentonite to ≤10%, then pass through a 300-mesh sieve, and take the under-sieve to obtain the bentonite raw material; the quality of the montmorillonite in the natural sodium-based bentonite is 100%. content greater than 60%, the pH value of the natural sodium-based bentonite is 9.4; the number of times of the washing is three times, and the washing method is: the undersize and distilled water are stirred and mixed evenly according to the mass ratio of 1:2 , static precipitation for 12 hours, and clear the supernatant.

[0036] Step 2, preparation of organ...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1. Preparation of bentonite raw material: Pass natural sodium-based bentonite through a 200-mesh sieve, take the undersize, and wash the undersize with distilled water several times to remove impurities to obtain washed bentonite; place the washed bentonite in an oven at temperature Dry for 20 hours under the condition of 90°C, and control the water content of the washed bentonite to ≤10%, then pass through a 250-mesh sieve, and take the sieve to obtain the bentonite raw material; the quality of the montmorillonite in the natural sodium-based bentonite is 100%. content greater than 60%, the pH value of the natural sodium-based bentonite is 10; the number of times of the washing is three times, and the washing method is: the undersize and distilled water are stirred and mixed evenly according to the mass ratio of 1:2 , static precipitation for 13 hours, and clear the supernatant.

[0043] Step 2, preparation of...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] Step 1. Preparation of bentonite raw material: pass natural sodium-based bentonite through a 300-mesh sieve, take the undersize, and wash the undersize with distilled water several times to remove impurities to obtain washed bentonite; place the washed bentonite in an oven at temperature Dry at 105°C for 22 hours, and control the water content of the washed bentonite to ≤10%, and then pass through a 280-mesh sieve to obtain the bentonite raw material; the quality of the montmorillonite in the natural sodium-based bentonite is 100%. content greater than 60%, the pH value of the natural sodium-based bentonite is 9; the number of times of the washing is three times, and the washing method is: the undersize and distilled water are stirred and mixed evenly according to the mass ratio of 1:2 , static precipitation for 12 hours, and clear the supernatant.

[0050] Step 2, preparation of organic bentonite: the bentonite ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com