Preparation method of ultra-fine grain high-temperature-resistant high-frequency manganese zinc ferrite

A manganese-zinc-ferrite, high-temperature-resistant technology, used in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of poor high-temperature characteristics and large high-frequency losses, and achieve enhanced high-temperature characteristics and high-frequency losses. Small, loss-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

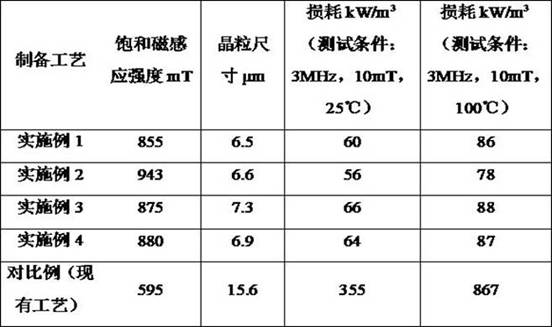

Examples

Embodiment 1

[0024] with Fe 2 o 3 , MnO 2 , ZnO as the main raw material, SnO 2 Dosing for auxiliary raw materials, Fe 2 o 3 Content 53mol%, MnO 2 Content 36mol%, ZnO content 11mol%, SnO 2 The content is 0.001wt%; after the batching is completed, a ball mill is carried out at a speed of 220 rpm, and the ball milling time is 2h; the raw material after the ball milling is pre-calcined, the pre-burning temperature is 850°C, and the holding time is 2h; Hetero-CaCO 3 Content 0.01wt%, V 2 o 5 Content 0.01wt%, TiO 2 Content 0.1wt%, Co 2 o 3 The content is 0.2wt%; the obtained raw materials are subjected to secondary ball milling, the speed of rotation is 220 rpm, and the ball milling time is 3h; after the secondary ball milling is completed, 10PVA is added for granulation; after that, pre-pressurized molding at room temperature is carried out, and the applied pressure is 3MPa; Then carry out high-temperature deformation alternately in the horizontal and vertical directions at a temper...

Embodiment 2

[0026] with Fe 2 o 3 , MnO 2 , ZnO as the main raw material, SnO 2 Dosing for auxiliary raw materials, Fe 2 o 3 Content 56mol%, MnO 2 Content 36mol%, ZnO content 8mol%, SnO 2 The content is 0.005wt%; after the batching is completed, a ball mill is carried out at a speed of 250 rpm, and the ball milling time is 3 hours; the raw materials after the ball milling are pre-calcined, the pre-calcination temperature is 950 ° C, and the holding time is 3 hours; Hetero-CaCO 3 Content 0.1wt%, V 2 o 5 Content 0.001wt%, TiO 2 Content 0.2wt%, Co 2 o 3 The content is 0.4wt%; the obtained raw materials are subjected to secondary ball milling, the speed of rotation is 250 rpm, and the ball milling time is 5h; after the secondary ball milling is completed, 15% PVA is added for granulation; then pre-pressurized at room temperature, and the applied pressure is 4MPa; followed by high-temperature deformation alternately in the transverse and longitudinal directions at a temperature of 1...

Embodiment 3

[0028] with Fe 2 o 3 , MnO 2 , ZnO as the main raw material, SnO 2 Dosing for auxiliary raw materials, Fe 2 o 3 Content 55mol%, MnO 2 Content 33mol%, ZnO content 12mol%, SnO 2 The content is 0.003wt%; after the batching is completed, a ball mill is carried out at a speed of 230 rpm, and the ball milling time is 2.5h; the raw material after the ball milling is pre-calcined, the pre-burning temperature is 900°C, and the holding time is 2.5h; Doping is carried out after completion , doped with CaCO 3 Content 0.05wt%, V 2 o 5 Content 0.005wt%, TiO 2 Content 0.15wt%, Co 2 o 3 The content is 0.3wt%; the obtained raw materials are subjected to secondary ball milling, the speed of rotation is 230 rpm, and the ball milling time is 4h; after the secondary ball milling is completed, 12% PVA is added for granulation; then pre-pressurized at room temperature, and the applied pressure is 3.5MPa; followed by high-temperature deformation alternately in the horizontal and vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com