Multi-dimensional micro-nano non-noble metal composite catalyst as well as preparation and application thereof

A composite catalyst and non-precious metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of low catalytic activity and high cost, and achieve the promotion of adsorption And dissociation, enhance the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] CoO@Co 2 Mo 3 O 8 Preparation of -525 composite catalyst:

[0048] 1) Weigh 10mmol of cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and sodium molybdate dihydrate (Na 2 MoO 4 ·2H 2 O) were dissolved in 87.5 mL of deionized water, respectively, and dispersed for 30 min under magnetic stirring at 500 r / min. Transfer the dispersed sodium molybdate aqueous solution to the cobalt chloride solution, and continue to disperse with magnetic stirring at 500 r / min for 1 hour to obtain a CoMo precursor solution. The bright red CoMo precursor solution was transferred to a 250 mL polytetrafluoroethylene reactor, hydrothermally reacted at 160 °C for 6 hours, cooled at room temperature, and the product was washed with deionized water and absolute ethanol, respectively, and then placed in an oven for 80 It was dried at °C for 8 hours to obtain CoMo precursor powder.

[0049] 2) 100 mg of CoMo precursor powder was added to the porcelain boat and placed in a tube furnace at a volu...

Embodiment 2

[0051] Co@Co 2 Mo 3 O 8 Preparation of -550 composite catalyst:

[0052] The only difference from Example 1 is that it is heated to 550° C. in step 2), and the rest are the same as in Example 1 to obtain Co@Co 2 Mo 3 O 8 -550 composite catalyst.

Embodiment 3

[0054] Co@Co 2 Mo 3 O 8 Preparation of -575 composite catalyst:

[0055] The only difference from Example 1 is that it was heated to 575° C. in step 2), and the rest were the same as in Example 1 to obtain Co@Co 2 Mo 3 O 8 -575 composite catalyst.

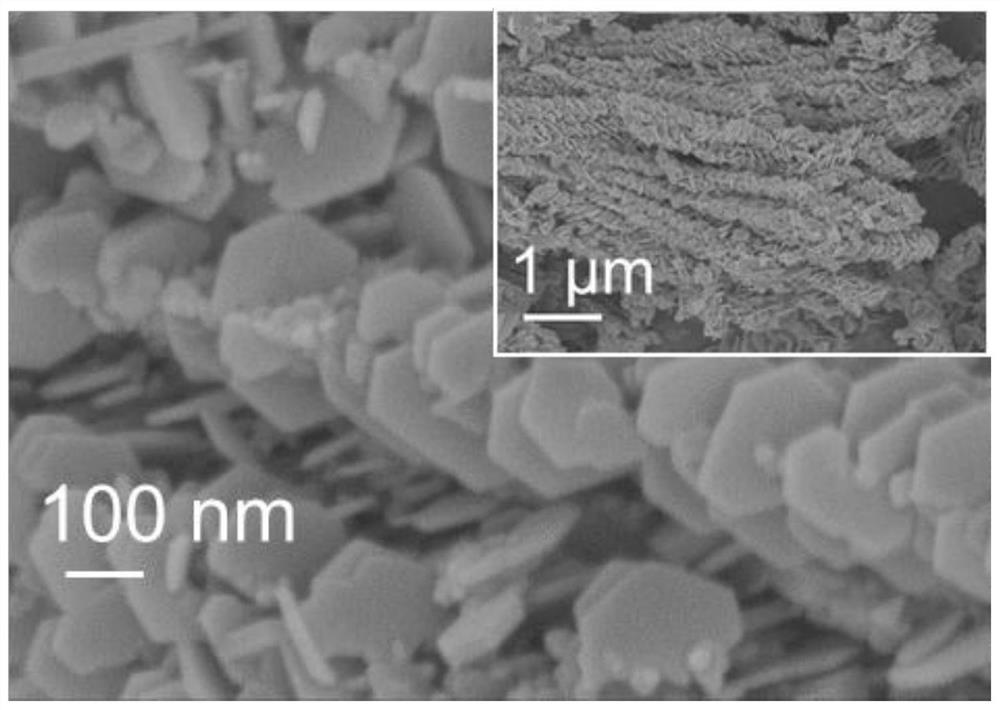

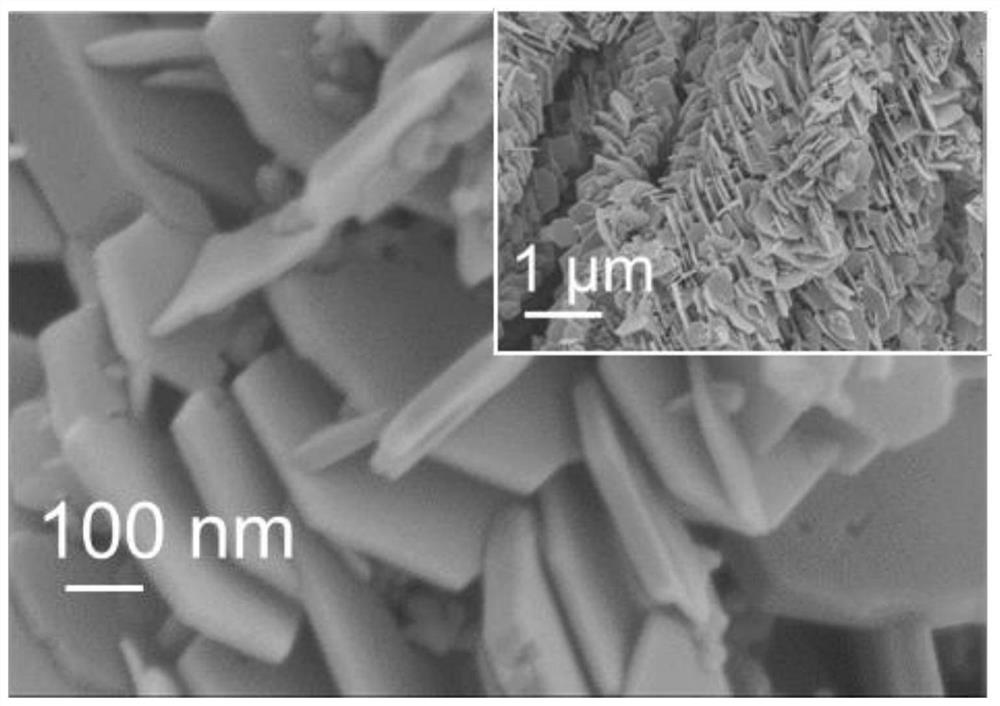

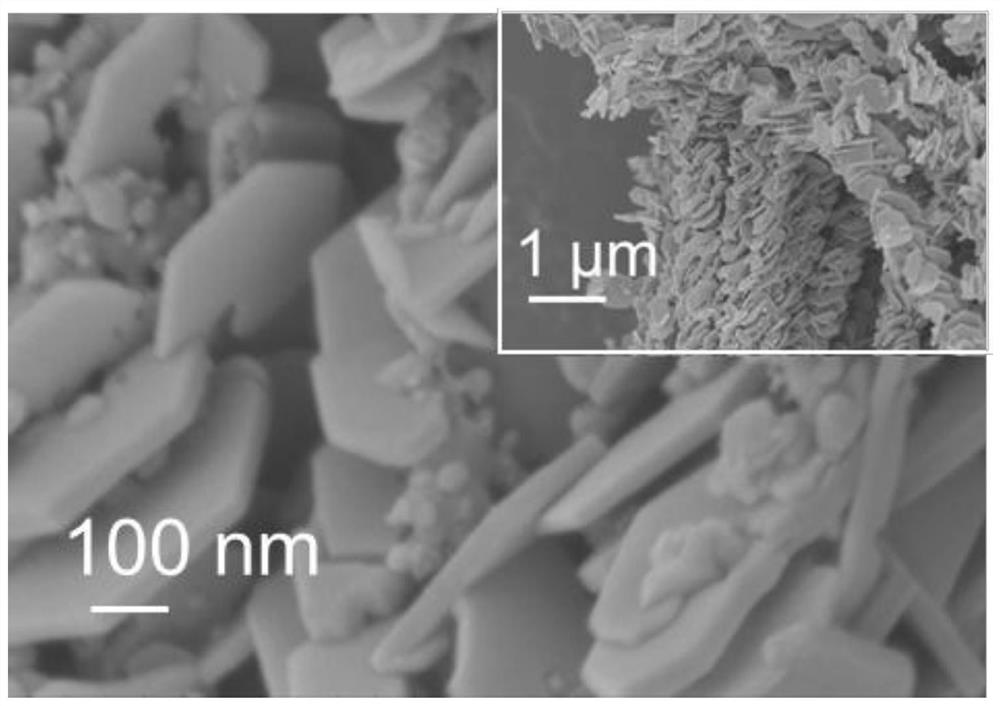

[0056] CoO@Co prepared in Example 2 Mo 3 O 8 -525, Co@Co 2 Mo 3 O 8 -550, Co@Co 2 Mo 3 O 8 The scanning electron microscope photo of -575 composite catalyst is as follows figure 1 , figure 2 , image 3 shown. The macroscopic appearances of the three are almost the same, showing a one-dimensional rod-like shape with a length of 2-10 μm and a width of 200-500 nm. The rod-shaped structure is composed of two-dimensional regular hexagonal nano-sheets with a thickness of 20-50 nm and a side length of 50-200 nm and zero-dimensional nanoparticles with a thickness of 10-50 nm, with uniform size and complete structure. Co@Co 2 Mo 3 O 8 -575 composite catalyst with CoO@Co 2 Mo 3 O 8 -525 and Co@Co 2 Mo 3 O 8 The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com