Carborane-based hydrostatic pressure fluorescence sensing material as well as preparation method and application of hydrostatic pressure fluorescent sensing material

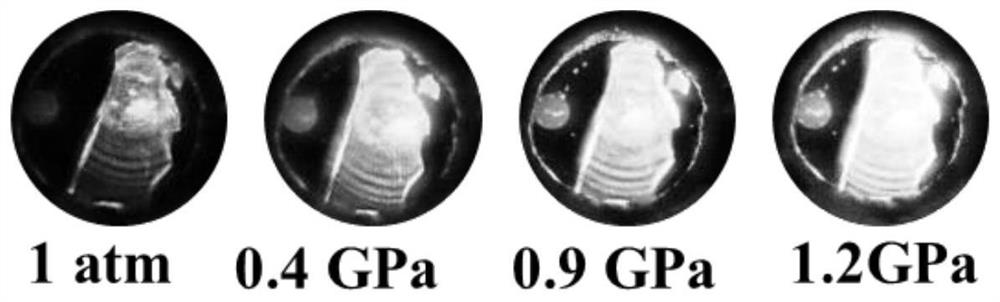

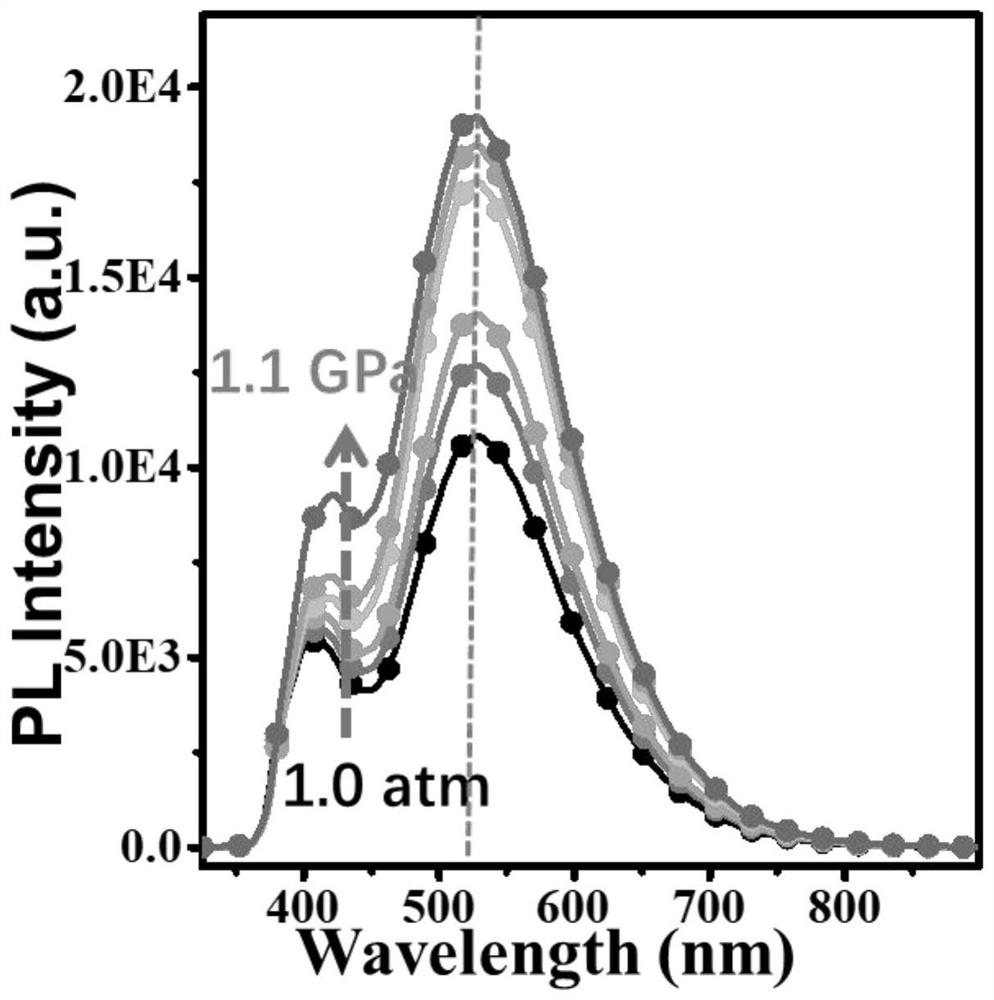

A fluorescence sensing and hydrostatic pressure technology, applied in the chemical field, can solve the problems of molecular luminescence intensity reduction, pressure sensor sensitivity reduction, fluorescence quenching, etc., achieve huge application potential, and overcome the effect of mechanofluorescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a pressure fluorescent sensing material based on carborane, comprising the following steps:

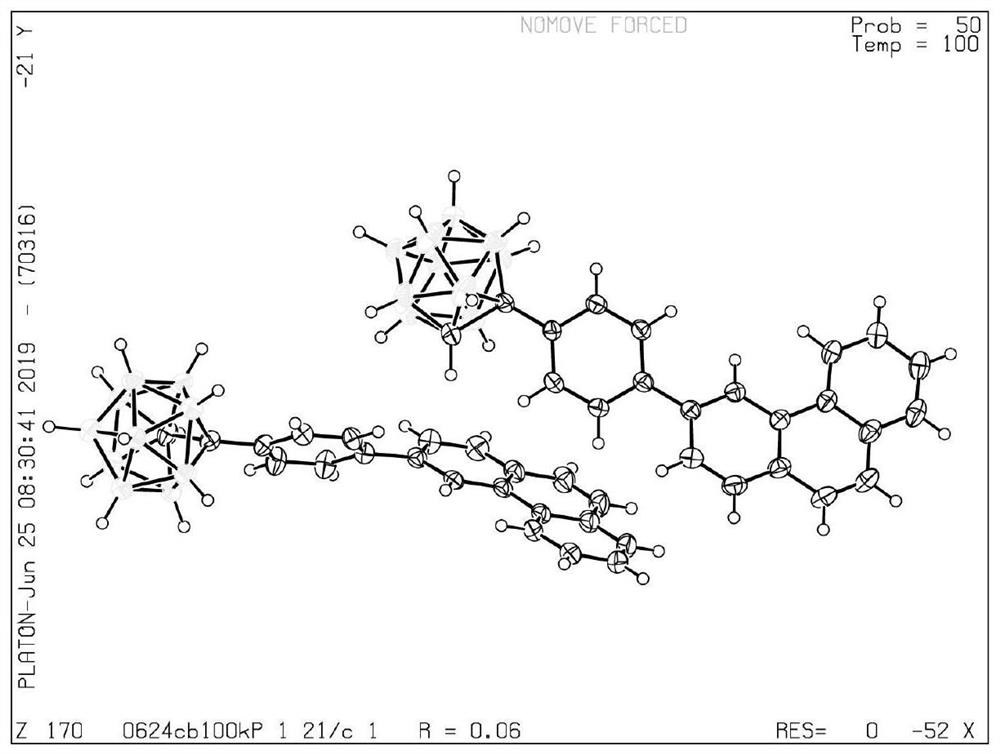

[0029] Weigh 0.299g (1mmol) of 4-carborane bromobenzene (I), 0.222g (1mmol) of phenanthrene boric acid (II), 0.091g (0.08mmol) of tetrakistriphenylphosphine palladium and 0.084g (0.8mmol) of sodium carbonate dissolved in 30mL tetrahydrofuran; under the protection of nitrogen atmosphere, heated and stirred at 90°C for 18h; at the same time, combined with thin layer chromatography (TLC) to determine the reaction process, after the reaction was terminated, the reaction system was extracted three times with water and dichloromethane, and then used The eluent of petroleum ether and dichloromethane in a volume ratio of 8:1 was purified by column chromatography to obtain 0.273 g of white powder with a yield of 35%, which was the target product carborane derivative (III).

[0030] The characterization data are as follows: 1H NMR (400MHz, Chloroform-d) δ8.84(d, J=...

Embodiment 2

[0033] A method for preparing a carborane-based pressure fluorescent sensing material, comprising the following steps:

[0034] Weigh 0.299g (1mmol) of 4-carborane bromobenzene (I), 0.267g (1.2mmol) of phenanthrene boric acid (II), 0.091g (0.08mmol) of tetrakistriphenylphosphine palladium and 0.084g (0.8mmol) of sodium carbonate ) was dissolved in 30mL tetrahydrofuran; under the protection of nitrogen atmosphere, heated and stirred at 90°C for 18h; at the same time, combined with thin layer chromatography (TLC) to determine the reaction process, after the reaction was terminated, the reaction system was extracted three times with water and dichloromethane, and then Purified by column chromatography with an eluent of petroleum ether and dichloromethane at 8:1 to obtain 0.288 g of a white powder with a yield of 37%, which is the target product carborane derivative (III).

Embodiment 3

[0036] A method for preparing a carborane-based pressure fluorescent sensing material, comprising the following steps:

[0037] Weigh 0.299g (1mmol) of 4-carborane bromobenzene (I), 0.244g (1.1mmol) of phenanthrene boric acid (II), 0.091g (0.8mmol) of tetrakistriphenylphosphine palladium and 0.084g (0.8mmol) of sodium carbonate ) was dissolved in 40mL of tetrahydrofuran; under the protection of nitrogen atmosphere, heated and stirred at 100°C for 18h; at the same time, combined with thin layer chromatography (TLC) to determine the reaction process, after the reaction was terminated, the reaction system was extracted three times with water and dichloromethane, and then Purified by column chromatography with petroleum ether and dichloromethane 8:1 eluent to obtain 0.280 g of white powder with a yield of 36%, which is the target product carborane derivative (III).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com