Spaceflight ablation heat-proof chopped fiber/phenolic aldehyde high-density premix, manual premixing preparation method and composite material thereof

A technology of chopped fiber and premix, which is applied in the field of composite materials, can solve the problem of low shear strength between layers, and achieve the effect of weakening the concept of layers, flame-retardant mechanical strength, and good molding fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

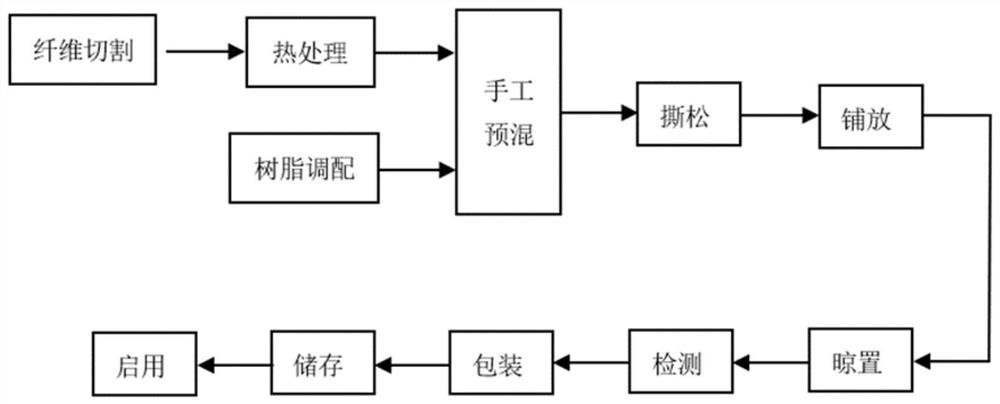

Method used

Image

Examples

Embodiment 1

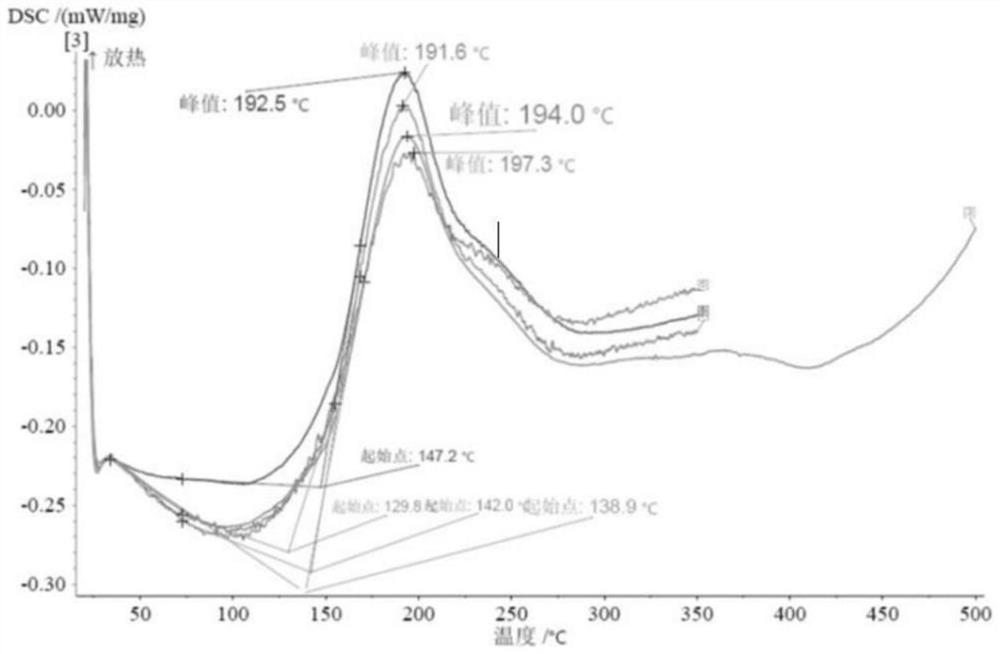

[0044] The raw materials for preparing the high-silica chopped fiber / aminophenolic premix and its composite material described in this embodiment include high-silica chopped fiber, aminophenolic resin, and absolute ethanol.

[0045] Among them, the aminophenol-formaldehyde resin adopts the product of brand 616, and its resin content is 60%. The high silica chopped fiber length is 50mm.

[0046] The preparation method of the high silica chopped fiber / aminophenol aldehyde premix and its composite material described in the present embodiment is specifically as follows:

[0047] 1. Filter the resin with a 100-200-mesh copper or stainless steel filter;

[0048] 2. The cut length of high silica chopped fiber is 24mm, and it is placed in an oven at (120±5)°C for 4 hours;

[0049] 3. Dilute 3.03kg of aminophenol-formaldehyde resin with 500ml of alcohol, stir well and form a liquid with appropriate concentration;

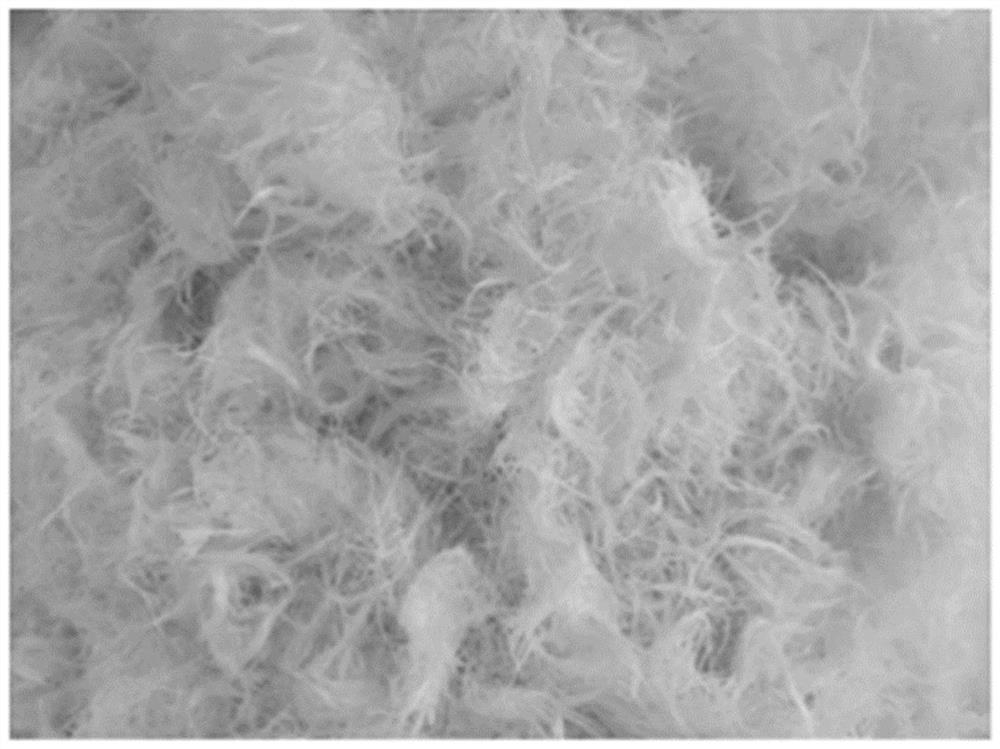

[0050] 4. Weigh 3kg of high-silica fiber, tear off the knots in it b...

Embodiment 2

[0059] The high-silica chopped fiber / magnesium phenolic premix and its composite material described in this embodiment are prepared from high-silica chopped fiber, magnesium phenolic resin, and absolute ethanol.

[0060] Wherein, the resin content of the magnesium phenolic resin is 55%. The high silica chopped fiber length is 50mm.

[0061] The preparation method of the high silica chopped fiber / magnesium phenolic premix and composite material described in the present embodiment is specifically as follows:

[0062] 1. Filter the resin with a 100-200-mesh copper or stainless steel filter;

[0063] 2. The cut length of high silica chopped fiber is 50mm, and it is placed in an oven at 120±5°C for 4 hours;

[0064] 3. Dilute 3.7kg magnesium phenolic resin with 1400ml alcohol, stir well and form a liquid with appropriate concentration;

[0065] 4. Weigh 3kg of high-silica fiber, tear off the knots in it by manual operation, and then mix the fiber and the prepared resin solution ...

Embodiment 3

[0073] The raw materials for preparing the viscose-based chopped carbon fiber / aminophenolic premix and its composite material described in this embodiment include viscose-based chopped carbon fiber, aminophenolic resin, and absolute ethanol.

[0074] Among them, the aminophenol-formaldehyde resin adopts the product of brand 616, and its resin content is 60%. The viscose-based chopped carbon fibers have a length of 20m.

[0075] The preparation method of the viscose-based chopped carbon fiber / aminophenolic premix and composite material described in the present embodiment is as follows:

[0076] 1. Filter the resin with a 100-200-mesh copper or stainless steel filter;

[0077] 2. The viscose-based chopped carbon fiber cut length is 40mm, and placed in an oven at 120±5°C for 4 hours;

[0078] 3. Dilute 1.50kg of aminophenol-formaldehyde resin with 900ml of alcohol, stir well and form a liquid with appropriate concentration;

[0079] 4. Weigh 1.00kg of viscose-based chopped car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com