Composite material with metal nitride-loaded nitrogen-doped carbon network structure and preparation method and application thereof

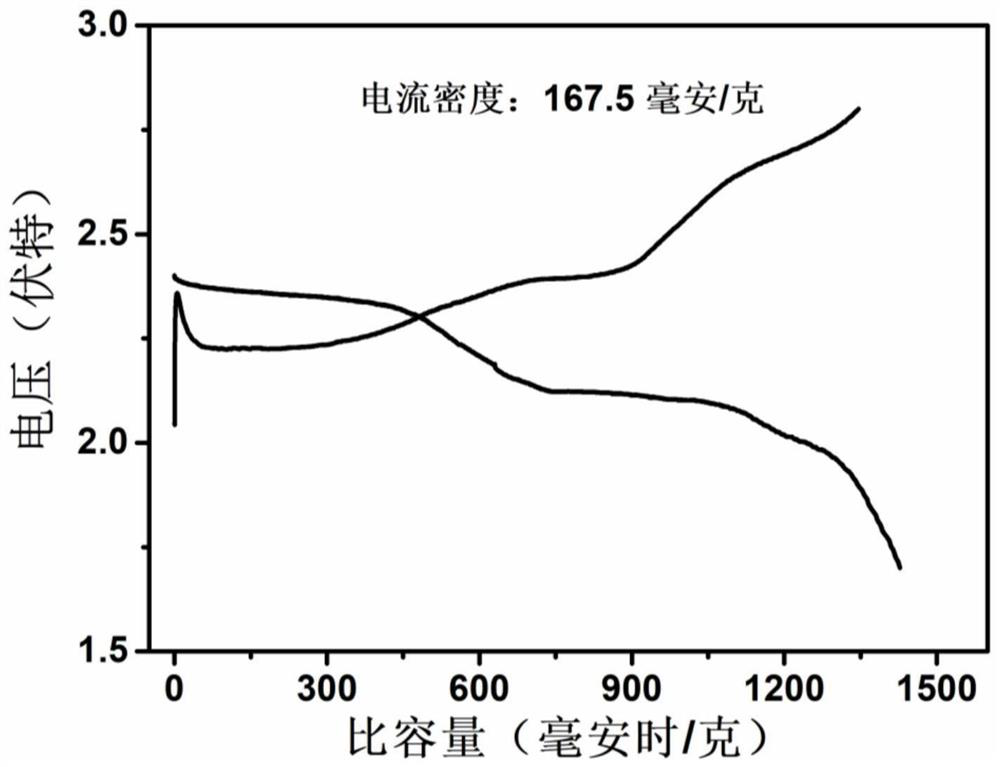

A nitrogen-doped carbon, network structure technology, applied in structural parts, electrochemical generators, active material electrodes, etc., can solve the problems of poor electronic conductivity of active materials, low active material loading, low reaction kinetics, etc. Effects of high loading, improved reaction kinetics, and improved rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of Ni 3 The compound of nitrogen-doped carbon network structure supported by N, the specific preparation method is as follows:

[0048] (1) Bamboo charcoal is alternately washed three times with ethanol and deionized water to remove impurities, soaked with 1mol / L sulfuric acid for 12 hours, and then dried at 60°C for use;

[0049] (2) 10g bamboo charcoal, 0.88g polyvinylpyrrolidone, 0.3g Ni(NO 3 ) 2 Disperse in 100mL deionized water, stir at 50-55°C to make it evenly mixed;

[0050] (3) Configure 0.2g / mL sodium hydroxide solution and 0.25g / mL ascorbic acid solution, slowly add these two solutions dropwise to the mixed solution in the above step (2), and stir at 50-55°C 3h, through suction filtration and deionized water washing, air drying at 60°C;

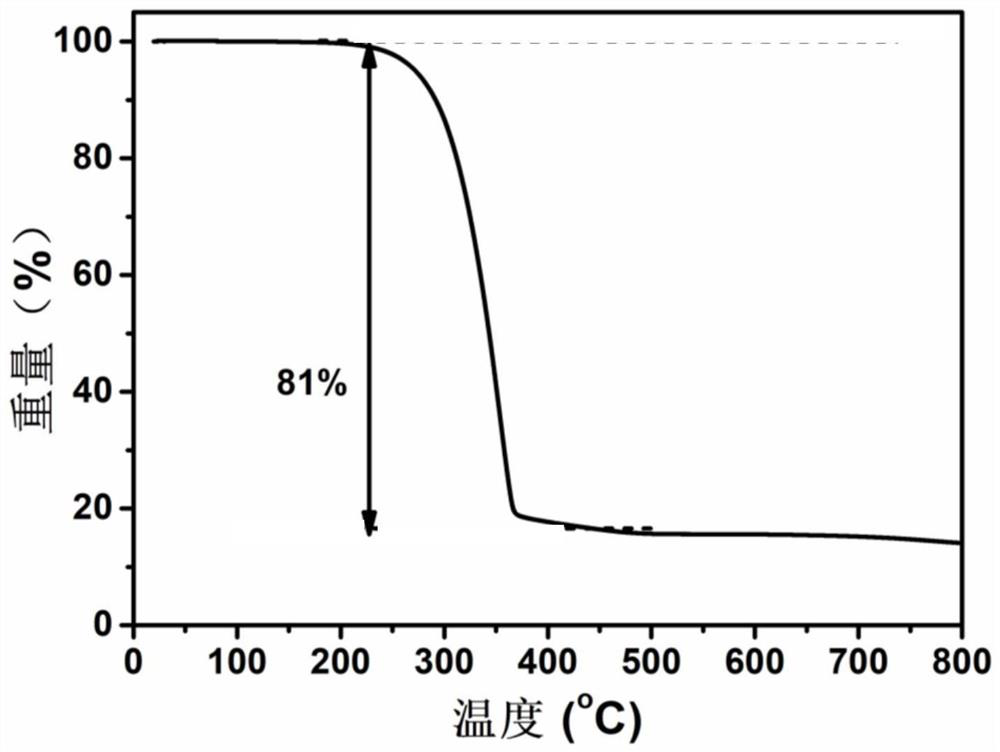

[0051] (4) the dried product in step (3) in NH 3 -Ar mixed atmosphere (wherein NH 3 The volume ratio of Ar and Ar is 1:1), at 550°C for 5h (heating rate 3°C / min), and cooled to room temperature to obtain t...

Embodiment 2

[0056] 1. Preparation of Fe 3 The compound of nitrogen-doped carbon network structure supported by N, the specific preparation method is as follows:

[0057] (1) The commercial bacterial cellulose was alternately washed with ethanol and deionized water three times to remove impurities, and then freeze-dried with liquid nitrogen at -196°C for 24 hours to prepare a fluffy three-dimensional network-shaped bacterial cellulose, which was cut into a circle with a diameter of 19 mm piece spare;

[0058] (2) Drop 25mg mL on each bacterial cellulose disk -1 FeCl 3 ·6H 2 50 μL of O ethanol solution, let it stand until the ethanol is completely volatilized;

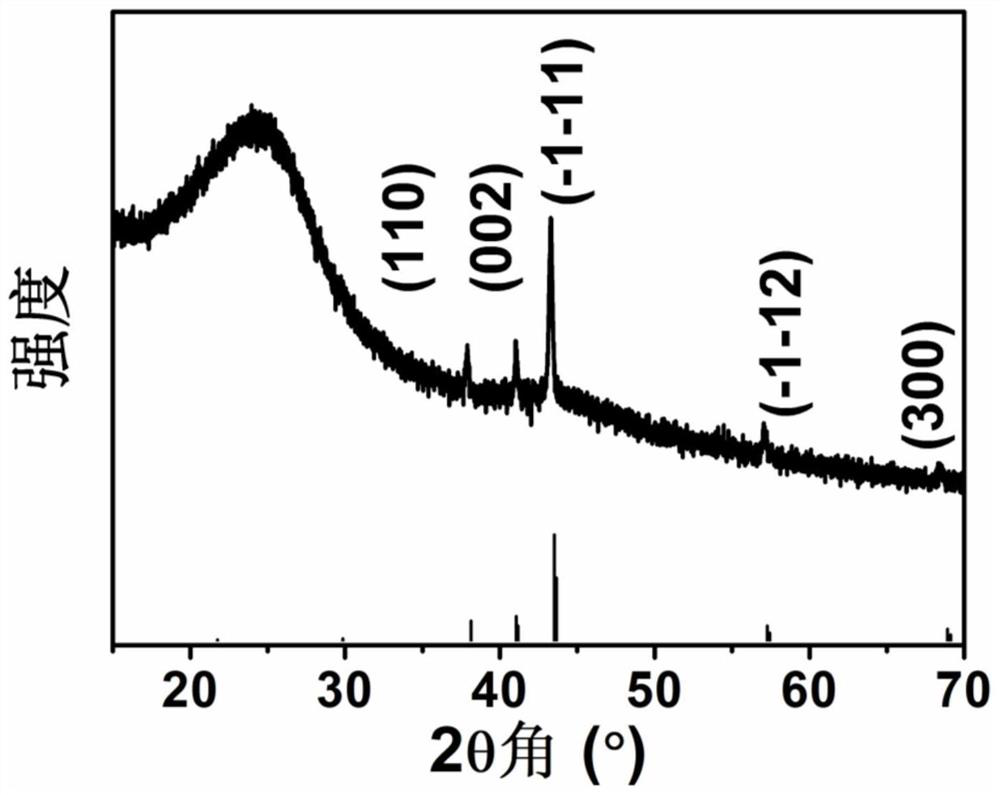

[0059] (3) The material after ethanol volatilization is placed in a tube furnace, and in pure NH 3 In the atmosphere, keep warm at 300 °C for 1 h, then keep warm at 800 °C for 2 h (heating rate is 5 °C / min), cool to room temperature, and obtain the target product (Fe 3 N-loaded nitrogen-doped carbon network composite), its XRD...

Embodiment 3

[0063] Preparation of Fe 1 Cu 2 The compound of nitrogen-doped carbon network structure supported by N, the specific preparation method is as follows:

[0064] (1) The commercialized bacterial cellulose was alternately washed three times with ethanol and deionized water to remove impurities, and the fluffy three-dimensional network bacterial cellulose was prepared by freeze-drying with liquid nitrogen, which was cut into discs with a diameter of 19 mm for later use;

[0065] (2) 10 discs of bacterial cellulose prepared in step (1), 0.05g CuCl 2 ·6H 2 Disperse O in 100mL deionized water, stir at 50-55°C to make it evenly mixed;

[0066] (3) Configure 0.1g / mL sodium hydroxide solution and 0.15g / mL ascorbic acid solution, slowly add these two solutions dropwise into the above-mentioned uniformly mixed solution, and stir at 50-55°C for 3h, filtered, washed with deionized water, and air-dried at 60°C;

[0067] (4) Place the dried product in 1g / mL of Fe 2 (SO 4 ) 3 In the aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com