Alkyl ether dithiophosphate collecting agent and preparation method and application thereof

A technology of alkyl ether-based dithiophosphate and alkyl ether-based dithiophosphoric acid, which is applied in solid separation, flotation and other directions, can solve the problem of low collection effect, inability to meet comprehensive utilization of mineral resources, single species, etc. problem, to achieve the effect of weak collecting ability, good foam mineralization effect and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of two (2-butoxyethyl) ammonium thiophosphate collectors:

[0047]Add 23.64 parts of ethylene glycol n-butyl ether into the reactor, and slowly add 13.08 parts of phosphorus pentasulfide, raise the temperature to about 85°C, and react for 3 hours while stirring, and a black oily liquid is obtained from the reaction. Use a constant pressure dropping funnel to load 6.81 parts of ammonia solution with a concentration of 25%, and slowly drop it into the reactor. The reaction is violent. After the reaction is over, a white precipitate is formed. The white solid obtained by filtering and decompressing distillation is di (2-Butoxyethyl)ammonium thiophosphate.

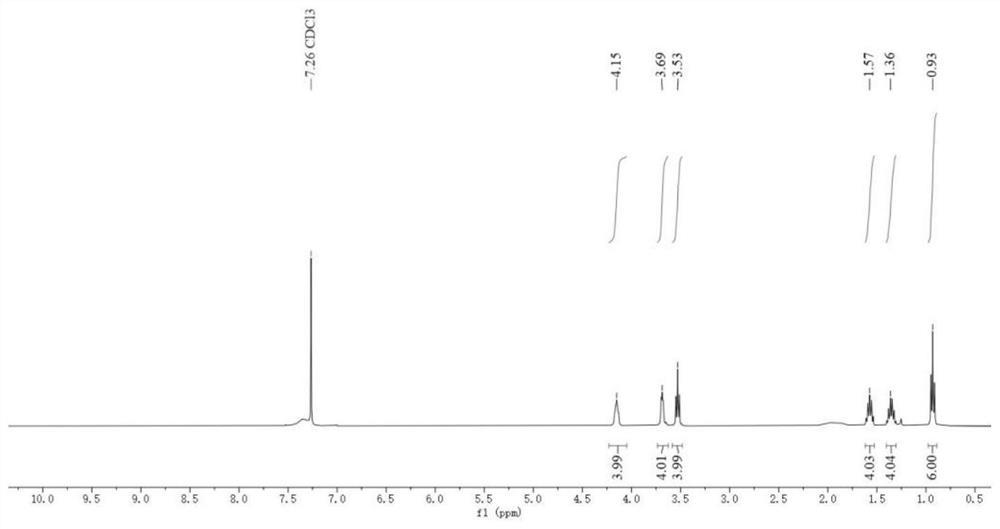

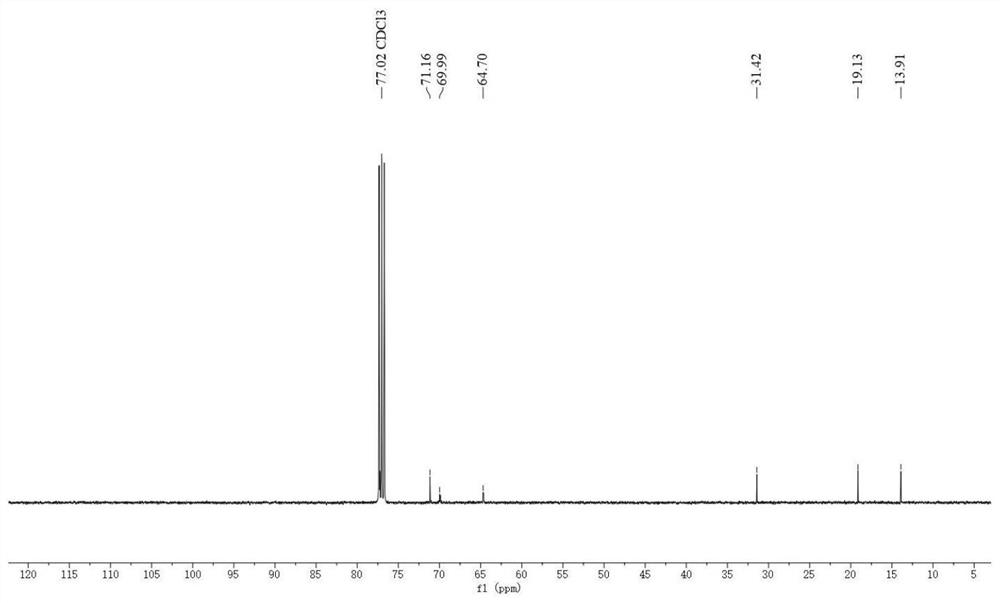

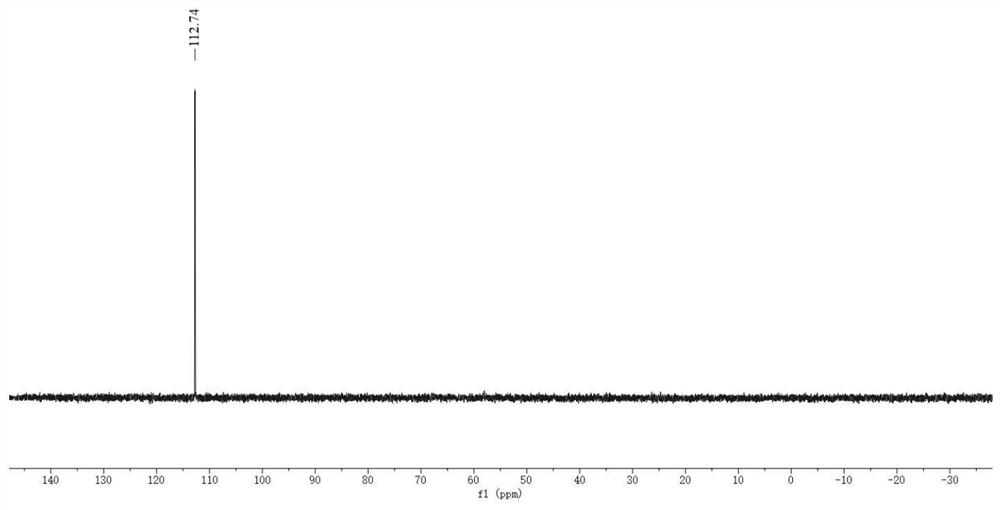

[0048] The obtained two (2-butoxyethyl) ammonium thiophosphate is characterized after purification, and its nuclear magnetic resonance 1 H. 13 C and 31 P picture see respectively figure 1 , figure 2 and image 3 , see the infrared spectrum Figure 4 , the NMR analysis of the target product is shown i...

Embodiment 2

[0055] Preparation of two (2-butoxyethyl) ammonium thiophosphate collectors:

[0056] Add 118.17 parts of ethylene glycol n-butyl ether into the reactor, and slowly add 60.4 parts of phosphorus pentasulfide, raise the temperature to about 90°C, and react for 4 hours while stirring, and the reaction will give a black oily liquid. Filling 34.06 parts of concentration with constant pressure dropping funnel is 25% aqueous ammonia solution, slowly drips in the reactor, reacts violently, treats that reaction finishes, has white precipitation to generate, and the white solid that filters, decompression distillation obtains is two ( 2-butoxyethyl) ammonium thiophosphate.

Embodiment 3

[0058] Preparation of two (2-propoxyethyl) ammonium thiophosphate collectors:

[0059] Add 63.12 parts of ethylene glycol propyl ether into the reactor, and slowly add 33.68 parts of phosphorus pentasulfide, raise the temperature to 90°C, and react for 5 hours while stirring, and the reaction gives a black-green oily liquid. Use a constant pressure dropping funnel to load 20.44 parts of ammonia solution with a concentration of 25%, slowly drip it into the reactor, the reaction is violent, after the reaction is finished, a white precipitate is formed, and the white solid obtained by filtering and vacuum distillation is distillate. Ammonium (2-propoxyethyl)thiophosphate.

[0060] The obtained two (2-propoxyethyl) ammonium thiophosphate is characterized after purification, and its nuclear magnetic resonance 1 H. 13 C and 31 P picture see respectively Figure 5 , Figure 6 and Figure 7 , see the infrared spectrum Figure 8 , the NMR analysis of the target product is shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com