Method for growing gold nanoflower particles with sharp tips by using metal films

A gold nanoflower and metal film technology, applied in the field of precious metal nanoparticle preparation, can solve the problems affecting the accuracy of measuring optical signals, difficult to remove surfactants, etc., and achieves strong local limitation of light field, short reaction time, good dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Add 0.08g CTAB and 0.56g CTAC to 19mL deionized water, then add 1mL 10mmol / L chloroauric acid aqueous solution, 200μL 10mmol / L silver nitrate aqueous solution, 33.5μL 12mol / L HCl aqueous solution and 160μL 100mmol / L ascorbic acid aqueous solution in sequence, and fully stirred to obtain a growth liquid.

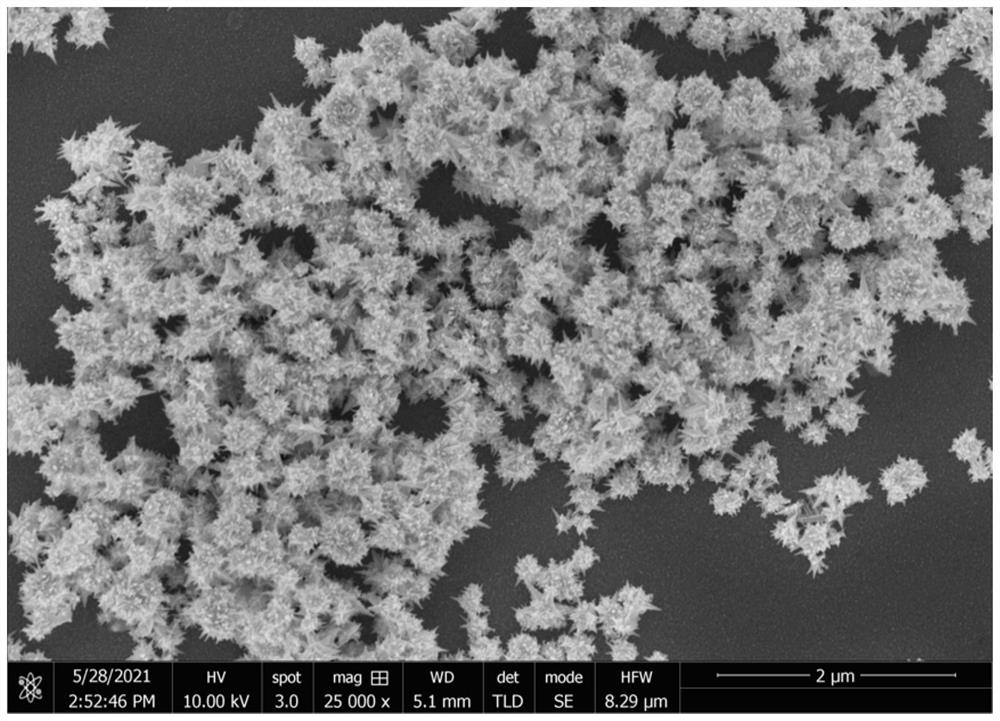

[0020] 2. Use a thermal evaporation coating instrument to vapor-deposit a silver film with a thickness of 10nm on a silicon wafer with a size of 5mm*5mm, and anneal at 200°C for 10min, then soak it in 2mL growth solution, and let it stand at room temperature After growing for 3 hours, wash with deionized water and ethanol to obtain gold nanoflower particles with sharp tips. Such as figure 1 As shown, the surface of the gold nanoflower particles is rough, with a sharp tip, and the diameter of the connection between the tip and the particle is small, and the particle size is mostly between 300 and 500 nm.

Embodiment 2

[0022] 1. Add 0.08g CTAB and 0.56g CTAC to 19mL deionized water, then add 1mL 10mmol / L chloroauric acid aqueous solution, 200μL 10mmol / L silver nitrate aqueous solution, 33.5μL 12mol / L HCl aqueous solution and 160μL 100mmol / L ascorbic acid aqueous solution, and Thoroughly stir to obtain growth liquid.

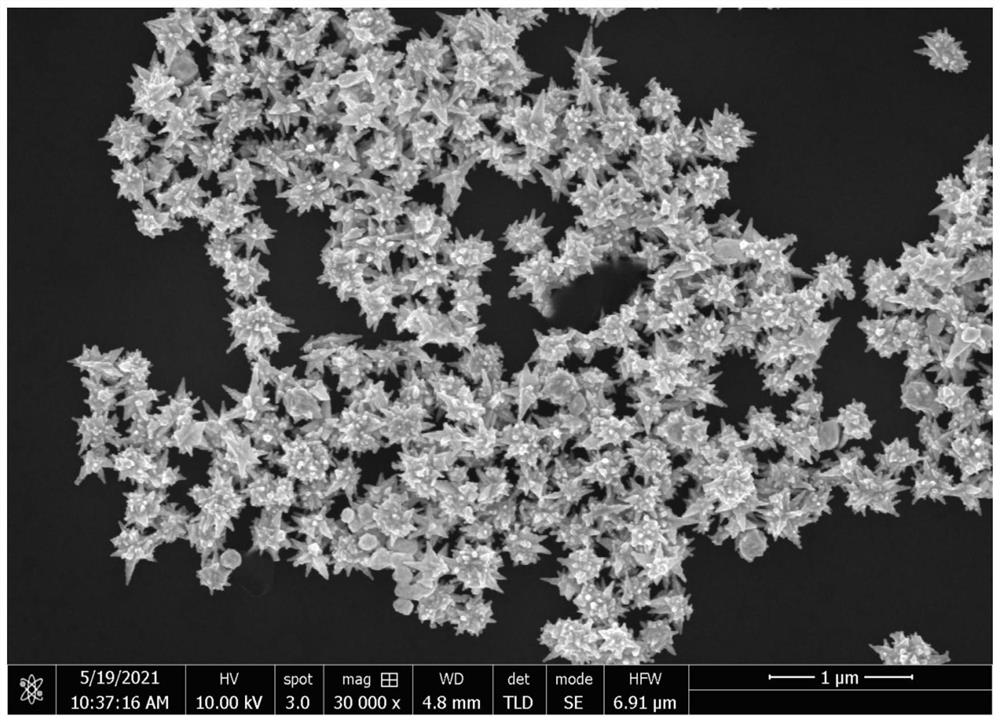

[0023] 2. Use a thermal evaporation coating instrument to vapor-deposit a gold film with a thickness of 10nm on a silicon wafer with a size of 5mm*5mm, and anneal at 200°C for 10min, then soak it in 2mL growth solution, and let it stand at room temperature After growing for 3 hours, wash with deionized water and ethanol to obtain gold nanoflower particles with sharp tips. Such as figure 2 As shown, the surface of the gold nanoflower particles is rough, with a sharp tip, and the diameter of the connection between the tip and the particle is relatively large, and the particle size is mostly between 200 and 500 nm.

Embodiment 3

[0025] 1. Add 0.08g CTAB and 0.56g CTAC to 19mL deionized water, then add 1mL 10mmol / L chloroauric acid aqueous solution, 200μL 10mmol / L silver nitrate aqueous solution, 33.5μL 12mol / L HCl aqueous solution and 160μL 100mmol / L ascorbic acid aqueous solution, and Thoroughly stir to obtain growth liquid.

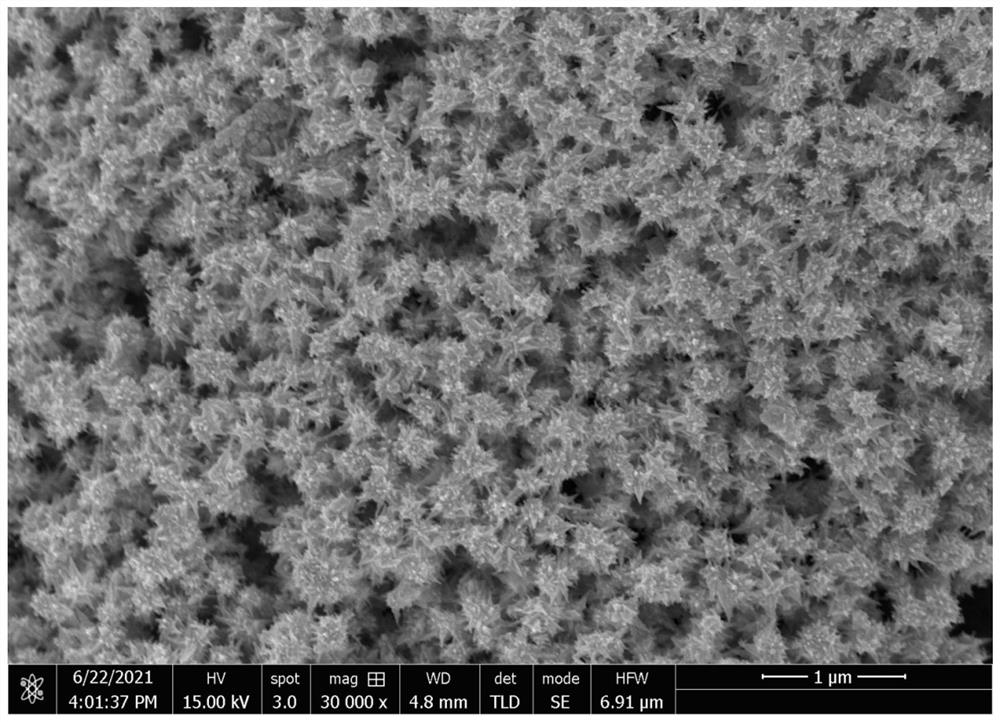

[0026] 2. Use a thermal evaporation coating instrument to evaporate an aluminum film with a thickness of 10nm on a silicon wafer with a size of 5mm*5mm, and anneal at 200°C for 10min, then soak it in 2mL growth solution, and let it stand at room temperature After growing for 3 hours, wash with deionized water and ethanol to obtain gold nanoflower particles with sharp tips. Such as image 3 As shown, the surface of gold nanoflower particles is rough, with sharp tips, and the particle size is mostly between 200-500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com