Sand mill method for producing submicron aluminum hydroxide and aluminium oxide

An aluminum hydroxide and sub-micron technology, applied in the field of alumina, can solve the problems of low whiteness, low dispersion, difficult production, etc., and achieve the effect of uniform particle size and reasonable crystal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Embodiment: a kind of sand mill method produces submicron aluminum hydroxide, comprises following raw material by weight:

[0040] 50 parts of high-sulfur bauxite, 2 parts of lime, 3 parts of circulating mother liquor, 5 parts of red mud washing liquid, 1 part of crystal seed, and 0.7 part of sodium hydroxide.

[0041] Described crystal seed comprises following raw material in parts by weight:

[0042] Aluminum hydroxide 1 part, water 1.2 parts.

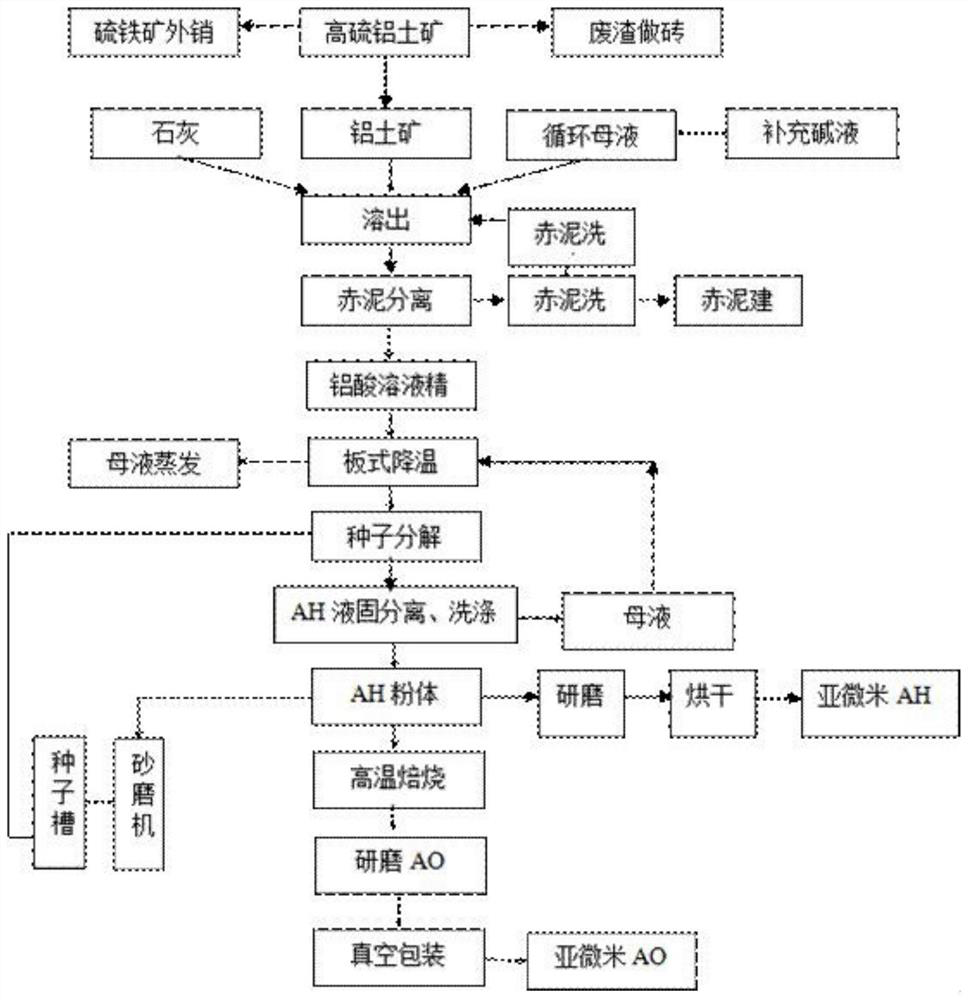

[0043] An alumina method for producing submicron aluminum hydroxide by a sand mill method, figure 1 as shown,

[0044] An alumina method for producing submicron aluminum hydroxide by sand mill method Equipment configuration process: high-sulfur bauxite - forced desulfurization bauxite concentrate powder and lime + circulating mother liquor - ball mill system grinding - ore pulp after desiliconization - High-pressure diaphragm pump-Bayer method high-pressure dissolution casing preheater-reaction kettle-nine-stage self-evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com