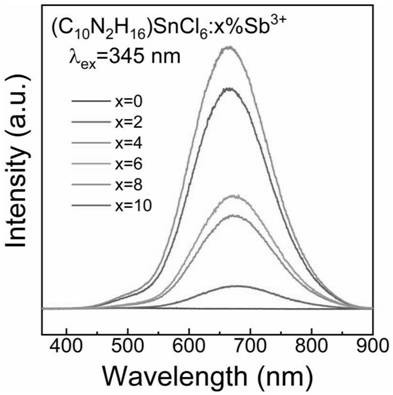

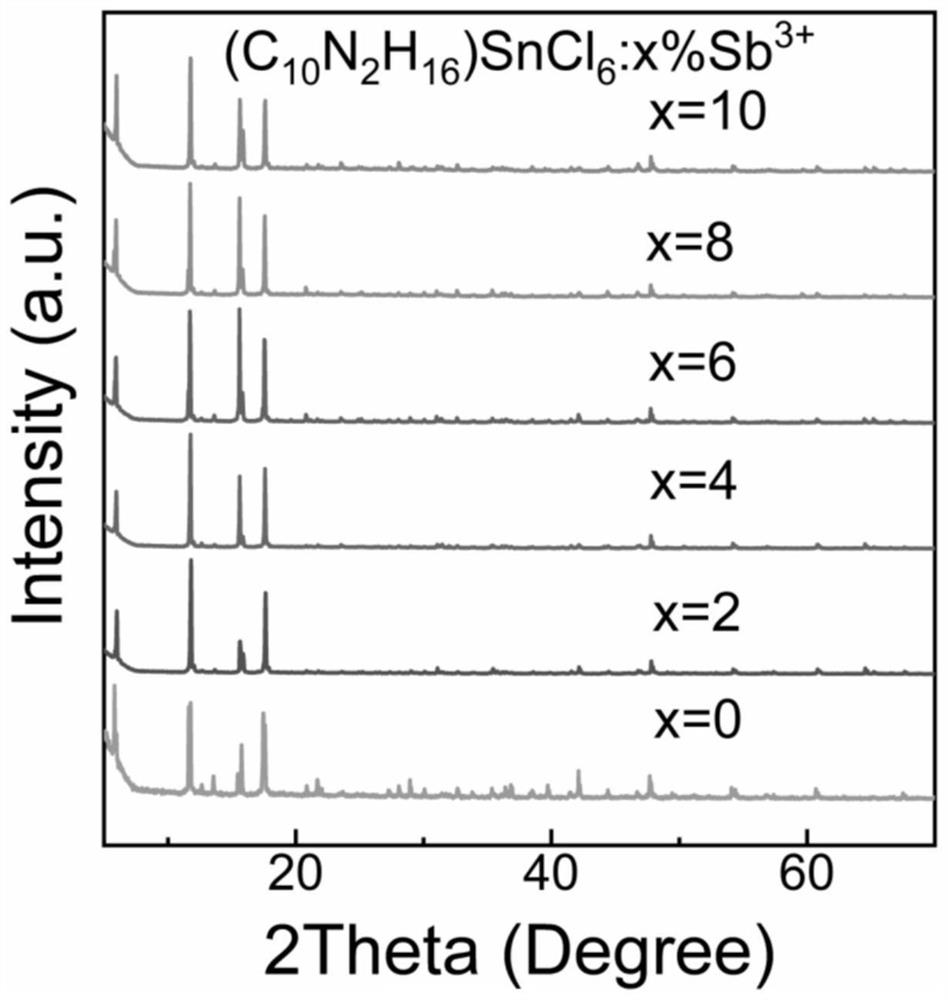

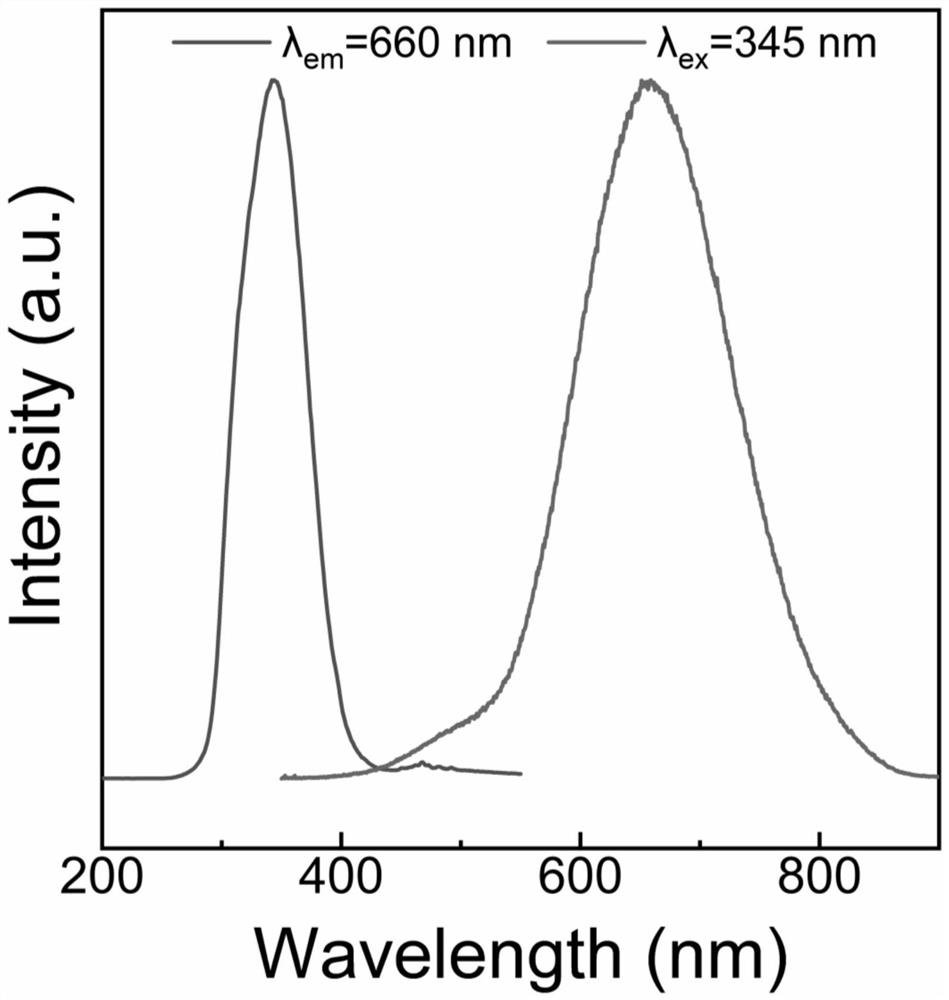

Antimony-doped organic-inorganic tin-based perovskite luminescent material and preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The present invention also provides a method for preparing an antimony-doped organic-inorganic metal halide material, comprising the following steps:

[0083] 1) After mixing 1-phenylpiperazine source, tin source, antimony source and hydrochloric acid solvent, and reacting by hydrothermal method, antimony-doped organic-inorganic metal halide is obtained.

[0084] In the present invention, the 1-phenylpiperazine source preferably includes 1-phenylpiperazine and / or 1-phenylpiperazine source acid salt, more preferably 1-phenylpiperazine or 1-phenylpiperazine Piperazine source acid salt.

[0085] In the present invention, the tin source preferably includes stannous chloride.

[0086] In the present invention, the antimony source preferably includes antimony chloride and / or antimony acetate, more preferably antimony chloride or antimony acetate.

[0087] In the present invention, the hydrochloric acid solvent preferably includes concentrated hydrochloric acid.

[0088] In...

Embodiment 1

[0114] (1) 0.98mmol stannous chloride and 0.02mmol antimony chloride are mixed and dissolved with 5ml concentrated hydrochloric acid to obtain a tin-antimony precursor solution;

[0115] (2) 1mmol 1-phenylpiperazine is mixed and dissolved with 5ml concentrated hydrochloric acid to obtain 1-phenylpiperazine precursor solution;

[0116] (3) Mix the precursor solutions prepared in steps (1) and (2), then place the mixed solution in a 25ml reaction kettle, raise the temperature to 110°C for 5h, keep the temperature for 10h, and drop to room temperature at 1°C / h to obtain the reaction Product mixing system.

[0117] (4) filtering the reaction product mixture system prepared in step (3), washing with ethanol, and freeze-drying to obtain antimony-doped organic-inorganic tin-based perovskite.

Embodiment 2

[0119] (1) 0.96mmol stannous chloride and 0.04mmol antimony chloride are mixed and dissolved with 5ml concentrated hydrochloric acid to obtain a tin-antimony precursor solution;

[0120] (2) 1mmol 1-phenylpiperazine is mixed and dissolved with 5ml concentrated hydrochloric acid to obtain 1-phenylpiperazine precursor solution;

[0121] (3) Mix the precursor solutions prepared in steps (1) and (2), then place the mixed solution in a 25ml reaction kettle, raise the temperature to 110°C for 5h, keep the temperature for 10h, and drop to room temperature at 1°C / h to obtain the reaction Product mixing system.

[0122] (4) filtering the reaction product mixture system prepared in step (3), washing with ethanol, and freeze-drying to obtain antimony-doped organic-inorganic tin-based perovskite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com