Mixed conduction type solid oxide electrolytic tank and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

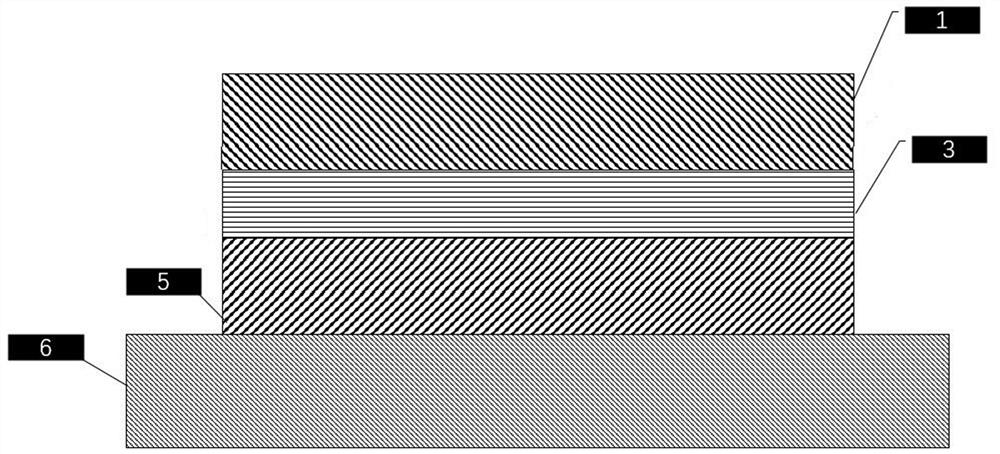

[0064] One embodiment of the present invention discloses a mixed conduction type solid oxide electrolytic cell, such as figure 1 As shown, it includes a porous metal support layer 6, a cathode layer 5, an electrolyte layer 3 and an anode layer 1 sequentially from bottom to top.

[0065] The porous metal support layer 6 is made of stainless steel whose main components are ferrite and cadmium. The porous metal support layer 6 is used as the support of the H-SOEC. Due to the addition of the metal support part, compared with other support methods, the electrons have the least path, so the polarization loss during the operation of the electrolytic cell can be reduced. Due to the good ductility of metal and better plasticity than ceramic materials, it is convenient to process, which can reduce the processing difficulty of H-SOEC and reduce the processing cost. Since the thermal conductivity of metal is better than that of ceramics, it can ensure that the H-SOEC will start up more q...

Embodiment 2

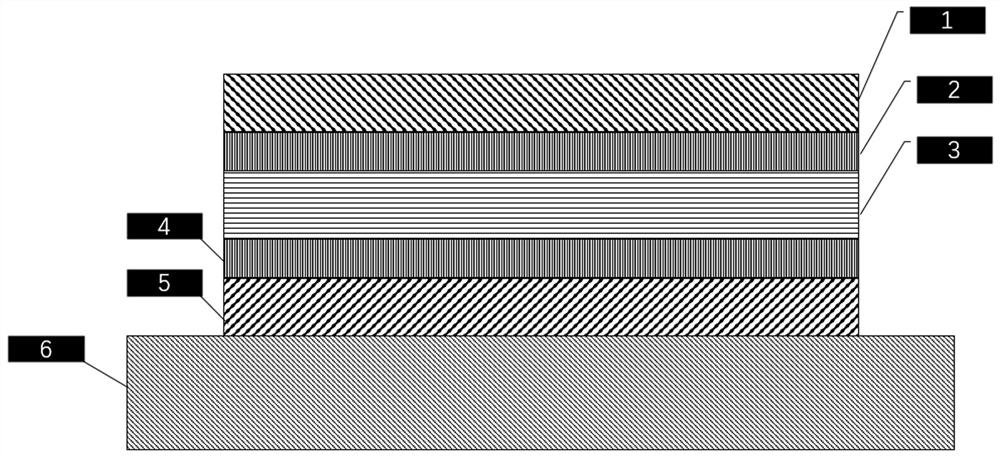

[0079] Optimizing on the basis of Example 1, the mixed conduction type solid oxide electrolytic cell also includes a functional layer one 4, a functional layer two 2, such as image 3 shown.

[0080] Functional layer one 4 is disposed between the cathode layer 5 and the electrolyte layer 3, and is used to fill the voids on the upper surface of the cathode layer and smooth its surface morphology. Preferably, the material used for the functional layer 4 is made by mixing the material of the electrolyte layer and the material of the cathode layer at a ratio of 1:1 and then ball milling in ethanol. This ratio can better modify the cathode morphology and fill the voids, thereby reducing the contact resistance of the cathode.

[0081] The functional layer 2 is arranged between the anode layer 1 and the electrolyte layer 3, and is used to fill the voids on the lower surface of the anode layer and smooth its surface morphology. Preferably, the material used for the functional layer ...

Embodiment 3

[0091] The present invention also discloses a method for preparing the mixed conduction type solid oxide electrolytic cell described in Example 1, which is characterized in that it includes the following steps:

[0092] S1. Prepare NBSCF powder, BZCYYb powder and NiO powder respectively;

[0093] S2. Prepare a porous metal support layer 6; mix ferrite and cadmium according to the mass ratio of 18.5:81.5, and then sequentially undergo calcination and pore-making processes to obtain a porous metal support layer 6; make the center of the porous metal support layer 6 a porous area , the edge is a non-porous region. Preferably, the porous area accounts for 60% to 80% of the total area, the pore diameter is 50 microns, and the distance between the holes is consistent;

[0094] S3. After mixing NBSCF powder and BZCYYb powder in a mass ratio of 4:1, add a binder, and sequentially undergo ball milling and calcination processes to obtain the cathode layer material, and uniformly spin-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com