Liquid crystal state composite fiber membrane as well as preparation and application thereof

A technology of composite fiber membrane and liquid crystal state, which can be used in prosthetics, drug delivery, textiles and paper making, and can solve problems such as biocompatibility gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation of embodiment 1LC / PU liquid crystal composite fiber film

[0059] (1) Preparation of CN-COC binary blend liquid crystal (LC):

[0060] CN and COC are respectively 0:100, 10:90, 20:80, 30:70, 40:60, 50:50, 60:40, 70:30, 80:20, 90:10, 100 according to the mass ratio :0 Blending. Add the mixture into the glass tube, then place the glass tube in an oven, adjust the temperature to 95°C and maintain it for 3 minutes, at this time, both liquid crystal compounds reach the clearing point, then fully stir until the two liquid crystals are completely mixed, and cool into powder Samples were stored in a dry box for later use.

[0061] (2) Preparation of liquid crystal composite fiber membrane:

[0062] Accurately weigh the CN-COC binary co-liquid crystal (LC) prepared by CN and COC in (1) according to the mass ratio of 30:70, add it into dichloromethane, stir at a speed of 100r / min until completely dissolved, and obtain LC / Dichloromethane solution; according to...

Embodiment 2

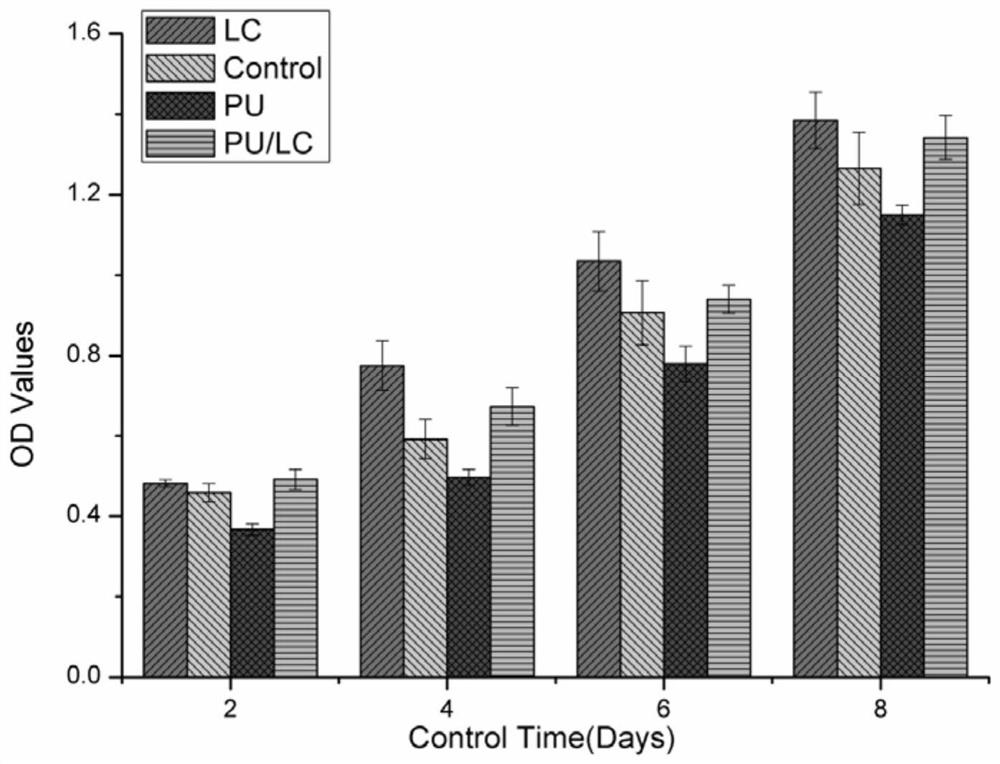

[0066] Performance analysis of embodiment 2LC / PU liquid crystal composite fiber membrane

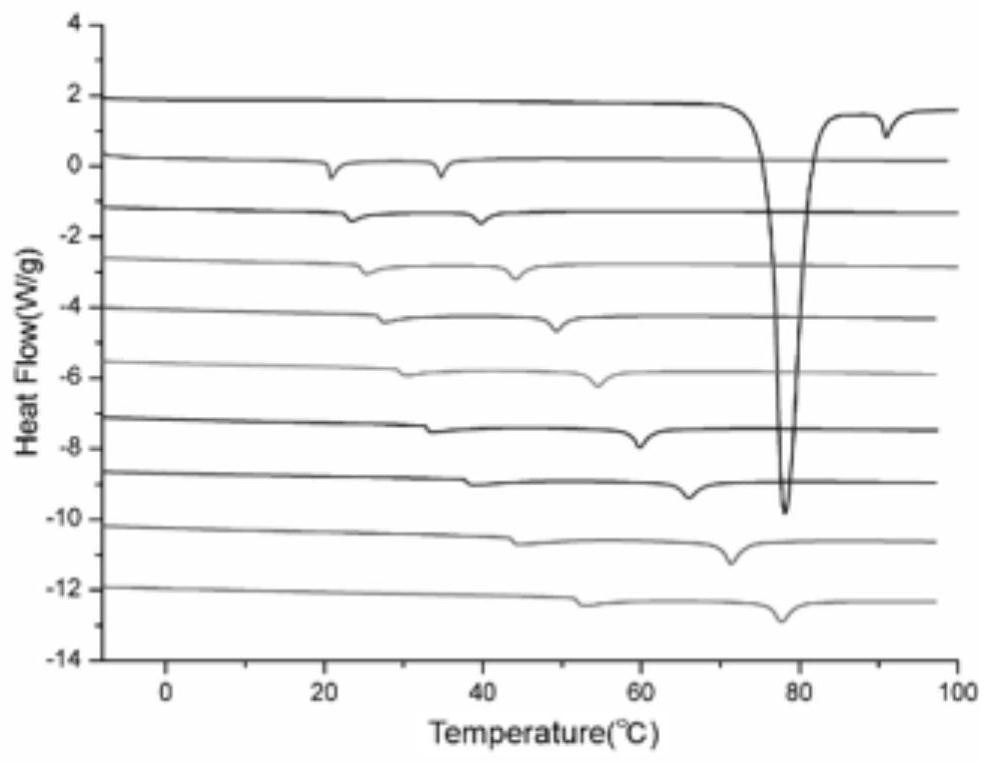

[0067] ① Weigh about 6-10 mg of dry CN-COC and LC / PU composite film, seal the aluminum crucible, put it into a differential scanning calorimeter, and raise the temperature from -20°C to 100°C at a rate of 5°C / min ℃, keep the temperature for 5min, cool down to -20℃, and heat up again, then drop to room temperature, the whole test process is under N 2 under protection. Observe and record the temperature during the change process of the liquid crystal composite film and take pictures. With the increase of the CN content, the liquid crystal phase temperature range of the CN-COC blended liquid crystal moves to a higher place. With the increase of the LC content in the LC / PU hybrid film, the mixed The liquid crystallinity of the film is more remarkable, and the liquid crystal phase interval also shifts to a higher position.

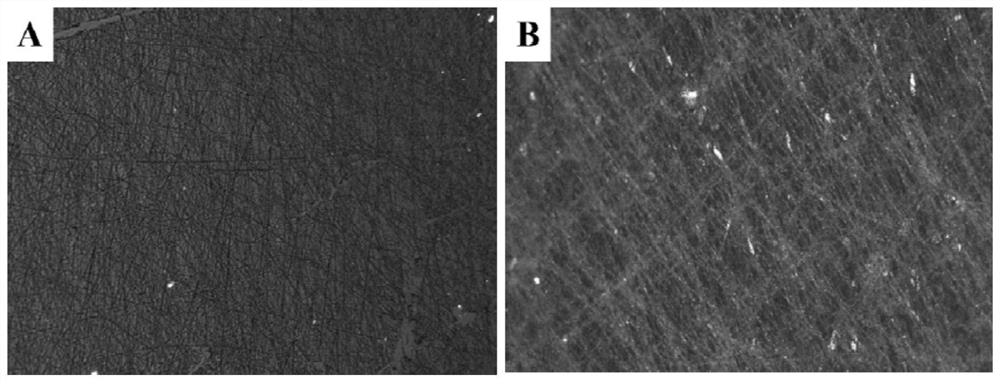

[0068] ② Place the CN-COC and LC / PU composite film on the inner gl...

Embodiment 3

[0070] Example 3 Preparation of Biomimetic Mineralized LC / PU Liquid Crystal Composite Fiber Membrane

[0071] The CN and COC were blended at a mass ratio of 30:70. Add the mixture into the glass tube, then place the glass tube in an oven, adjust the temperature to 95°C and maintain it for 3 minutes, at this time, both liquid crystal compounds reach the clearing point, then fully stir until the two liquid crystals are completely mixed, and cool into powder sample. Then add it into dichloromethane, stir until completely dissolved at a speed of 100r / min, and obtain LC / dichloromethane solution; according to the mass ratio of LC and PU of 40:60, accurately weigh PU and add it to the obtained LC / dichloromethane In the solution (wherein, the total concentration of PU is 8%), the mixture is continuously stirred until the solute is completely dissolved to obtain a LC / PU mixed solution.

[0072] Introduce the fully dissolved LC / PU mixed solution into the micro-syringe pump, select the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com